Method for inspection of magnetic recording medium, magnetic recording medium, and magnetic recording/reproducing device

A technology of magnetic recording medium and inspection method, which is applied in the field of magnetic recording medium inspection, magnetic recording medium and magnetic recording and reproducing device, and can solve the problems of unstable magnetic recording and reproducing characteristics, inability to remove extremely small amounts of pollutants, etc., and achieve magnetic recording Stable regeneration characteristics, less pollution, and excellent environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1~4

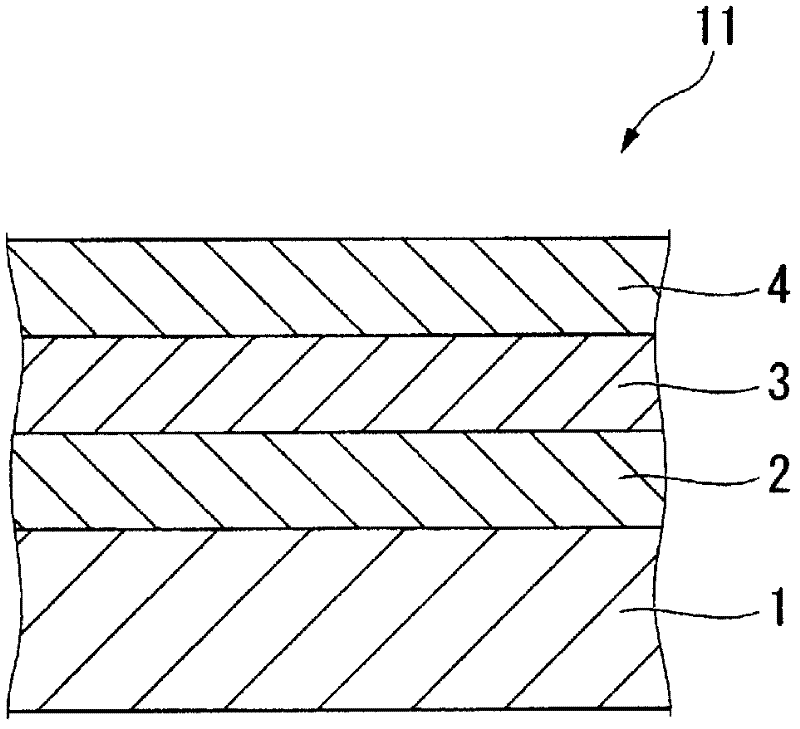

[0085] As a non-magnetic substrate, a crystallized glass substrate (manufactured by Ohara Corporation) having an outer diameter of 65 mm, an inner diameter of 20 mm, and a thickness of 0.635 mm was prepared. Next, a texture (texture) is applied to this non-magnetic substrate, and it is fully washed and dried. Next, after placing the above-mentioned textured non-magnetic substrate in the chamber of a DC magnetron sputtering device (manufactured by ANELBA (Japan), C3040), exhaust until the ultimate vacuum degree in the above-mentioned chamber is 2×10 -7 Holder (2.7×10 -5 Pa).

[0086] Using a DC sputtering method, a FeCoB film was sequentially formed as a soft magnetic layer, a Ru film was formed as an intermediate layer, and a 25Fe-30Co-45Pt film was formed as a magnetic layer on a non-magnetic substrate. The film thicknesses of the respective layers obtained by film formation were 60 nm for the soft magnetic layer, 10 nm for the intermediate layer, and 15 nm for the magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com