Scale calibrating device and scale calibrating method for hopper scale with hopper or hopper bin horizontal detection

A hopper scale and hopper technology, applied in the field of measurement correction and calibration devices, can solve the problems of damage to the load cell, uneven load distribution, high labor intensity, etc., and achieve the effect of reducing labor intensity, improving the qualification rate and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

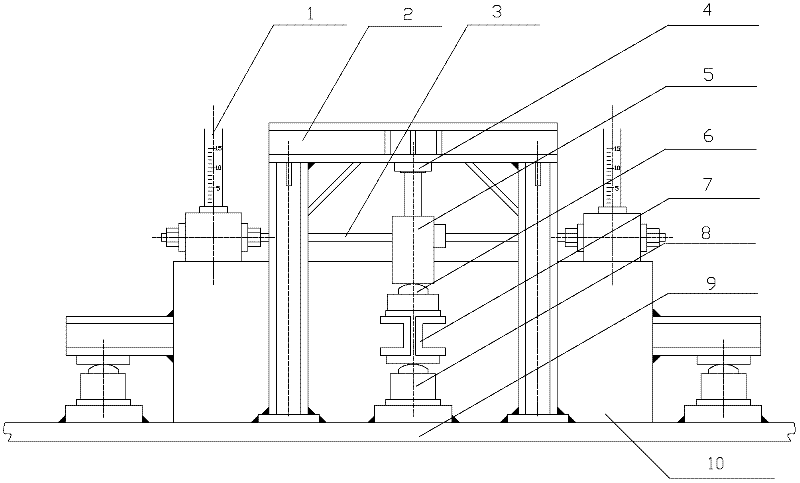

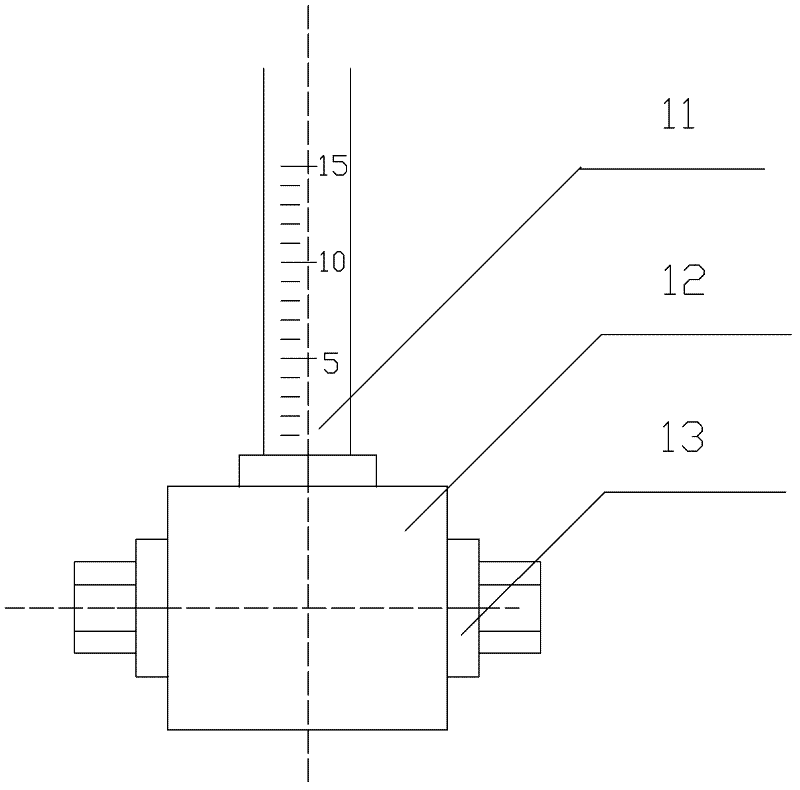

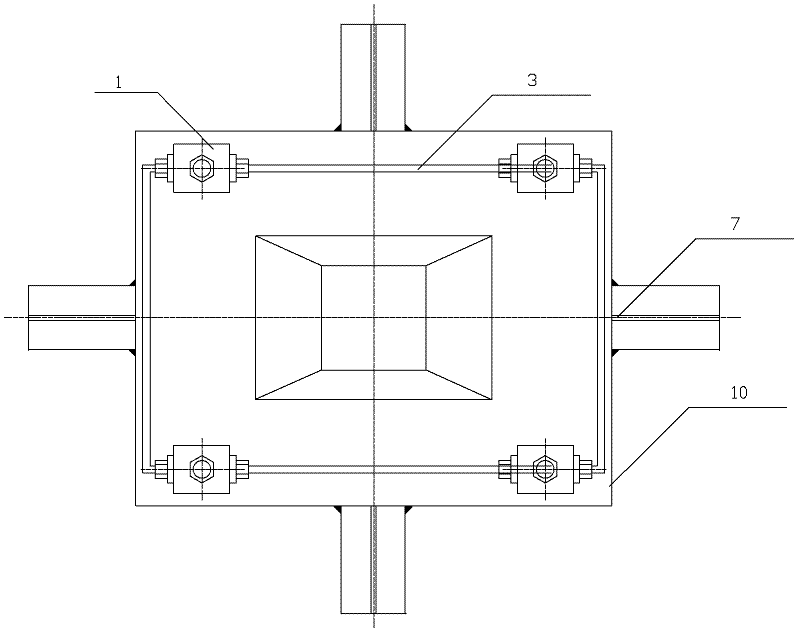

[0036] see figure 1 , figure 2 , image 3 According to this embodiment, the hopper scale calibration device with hopper / silo level detection mainly includes a magnetic level 1, a gantry frame 2, a magnetic level connecting hose 3, a spacer 4, a jack 5, and a standard scale for calibration. A load cell 6, a pressure application platform 7 and a weighing display instrument matched with four standard load cells 6; wherein, the gantry 2 is fixedly connected with the supporting beam or the foundation 9, and a jack is placed below the center position of the horizontal beam of the gantry 2 5. A pad 4 with a thickness of 20 to 60 cm is placed between the gantry 2 and the jack 5 to adjust the distance between the gantry 2 and the jack 5 placed under the pad 4; On the upper surface of the load cell 6, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com