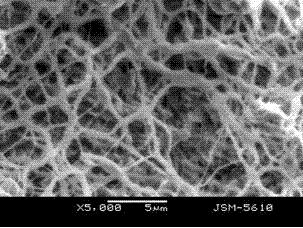

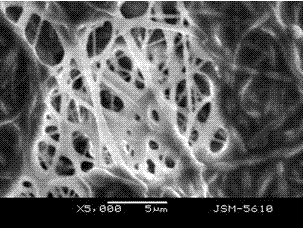

Method for preparing SiC/C nano-fiber membrane by electrostatic spinning

A nanofiber membrane and electrospinning technology, which is applied in the direction of spinning solution preparation, fiber treatment, fiber chemical characteristics, etc., can solve the problems of low yield, limited length of SiC products, complicated process, etc., and achieve high efficiency and spinnable Good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] N 2 Add 7.2mL of dimethyldichlorosilane, 20.75mL of diphenyldichlorosilane and 9.3mL of trimethylchlorosilane dropwise into a 1L reaction kettle containing 9.0g of Na and 200mL of xylene in 15min, at 98℃ After refluxing for 24 hours, suction filtration, the filtrate was added dropwise into anhydrous methanol to obtain a white precipitate, which was washed with methanol and deionized water respectively to obtain a dimethylsilane-diphenylsilane copolymer. The polysilane copolymer has a weight average molecular weight of 600 and a molecular weight distribution coefficient of 1.46 as determined by GPC. Weigh 1 g of dimethylsilane-diphenylsilane copolymer and dissolve it in xylene to prepare a 5% solution (A); weigh 1 g of polyacrylonitrile and dissolve it in DMF to prepare a 5% solution (B). Measure 1mL of A solution and 5mL of B solution, mix them and stir for 30min to make spinning solution. The above spinning solution was sucked into the needle tube and spun at a volta...

Embodiment 2

[0023] N 2 Under protection, add 12mL of dimethyldichlorosilane, 12.5mL of diphenyldichlorosilane and 0.5mL of trimethylchlorosilane dropwise into a 1L reaction kettle containing 7.5g of Na and 200mL of xylene in 15 minutes, and reflux at 113°C After 16 hours, it was filtered with suction, and the filtrate was added dropwise to methanol to obtain a white precipitate, which was washed with methanol and deionized water respectively to obtain a dimethylsilane-diphenylsilane copolymer. The polysilane copolymer has a weight-average molecular weight of 10,000 and a molecular weight coefficient of 1.50 as determined by GPC. Weigh 2 g of dimethylsilane-diphenylsilane copolymer and dissolve in tetrahydrofuran to prepare a 10% solution (A); weigh 2 g of polyacrylonitrile and dissolve in DMF to prepare a 10% solution (B). Measure 5mL of solution A and 1mL of solution B, mix them and stir for 30min to prepare spinning solution. The above-mentioned spinning solution was sucked into the n...

Embodiment 3

[0025] N 2 Under protection, the mixture of 12.0mL dimethyldichlorosilane, 20.75mL diphenyldichlorosilane and 3.0mL trimethylchlorosilane was added dropwise in 15 minutes to a 1L reaction kettle containing 9.8g Na and 200mL xylene, at 138°C After refluxing for 10 h, suction filtration was performed, and the filtrate was added dropwise to methanol to obtain a white precipitate, which was washed with methanol and deionized water respectively to obtain a dimethylsilane-diphenylsilane copolymer. The weight-average molecular weight of the polysilane copolymer measured by GPC is 2400, and the molecular weight coefficient is 1.35. Weigh 2 g of dimethylsilane-diphenylsilane copolymer and dissolve in tetrahydrofuran to prepare a 20% solution (A); weigh 1.5 g of polyacrylonitrile and dissolve in DMF to prepare a 15% solution (B). Measure 3mL each of A and B solutions, mix them and stir for 30min to make spinning solution. The above-mentioned spinning solution was sucked into the needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com