Efficient leaching technology of metal ions in chrysotile nanofiber

A nanofiber and chiropterite technology, which is applied in the field of efficient leaching of metal ions in silica nanofibers, can solve the problems of low pH value of tail acid, environmental hazards, high acid concentration, etc., achieve efficient leaching and reduce environmental costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

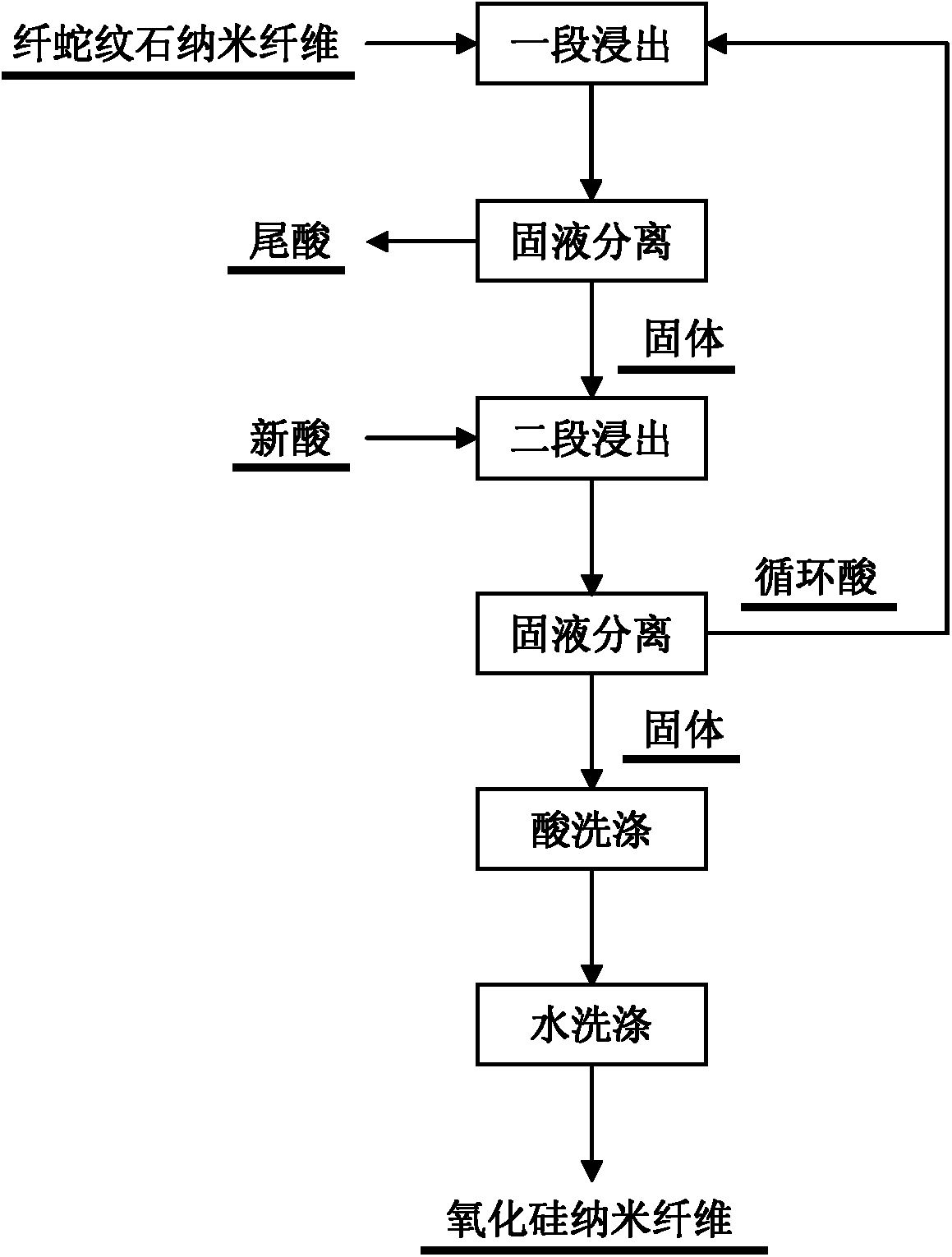

[0034] Two-stage hydrochloric acid countercurrent leaching, see the flow chart figure 1 . Hydrochloric acid solution with a hydrogen ion concentration of 0.8 mol / L was used as the leaching agent, and hydrochloric acid was added at a solid-to-liquid ratio of 1:50 g / ml. The leaching time of each section was 2 h, the temperature was 80 ° C, and the stirring speed was 500 rpm. Fresh chrysotile nanofiber solids were added in the first stage, and fresh acid was added in the second stage. The direction of the solid is one stage → two stages, and the direction of the liquid is two stages → one stage. At the same time, add 2% leaching aid oxalic acid in the second stage. The pH of the tail acid discharged after the first stage of leaching is measured each time. After 8 to 10 batches of leaching, the pH value of the tail acid is stable at about 0.8, and the countercurrent leaching system reaches equilibrium. After the solid discharged from the second stage is washed with hydrochloric...

Embodiment 2

[0036] The operation process is the same as in Example 1, except that the hydrochloric acid solution with a hydrogen ion concentration of 0.5 mol / L is used as the leaching agent, and hydrochloric acid is added at a solid-to-liquid ratio of 1:80 g / ml. The leaching time of each section is 4 hours, and the temperature is 95 ° C. The stirring speed is 700 rpm. Add 8% leaching aid sodium citrate in the second stage. The pH of the tail acid discharged after the first stage of leaching is measured each time. After 8 to 10 batches of leaching, the pH value of the tail acid is stable at about 0.8, and the countercurrent leaching system reaches equilibrium. After the solid discharged from the second stage is washed with hydrochloric acid of pH=2 and deionized water several times, silicon oxide nanofibers with a purity greater than 92% are obtained.

Embodiment 3

[0038] The operation process is the same as in Example 1, except that the hydrochloric acid solution with a hydrogen ion concentration of 1.0 mol / L is used as the leaching agent, and hydrochloric acid is added at a solid-to-liquid ratio of 1:40 g / ml. The leaching time of each section is 1 h, and the temperature is 60 ° C. The stirring speed is 400 rpm. Add 5% leaching aid sodium oxalate in the second stage. The pH of the tail acid discharged after the first stage of leaching is measured each time. After 8 to 10 batches of leaching, the pH value of the tail acid is stable at about 0.8, and the countercurrent leaching system reaches equilibrium. After the solid discharged from the second stage is washed with hydrochloric acid of pH=2 and deionized water several times, silicon oxide nanofibers with a purity greater than 92% are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com