Preparation method of phenolic resin microballoons and method for preparing phenolic resin-based carbon spheres by use of preparation method

The technology of phenolic resin and microspheres is applied in the field of preparation of resin microspheres and carbon spheres, which can solve the problems of high cost, complicated preparation method, difficult control of the diameter of microspheres, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

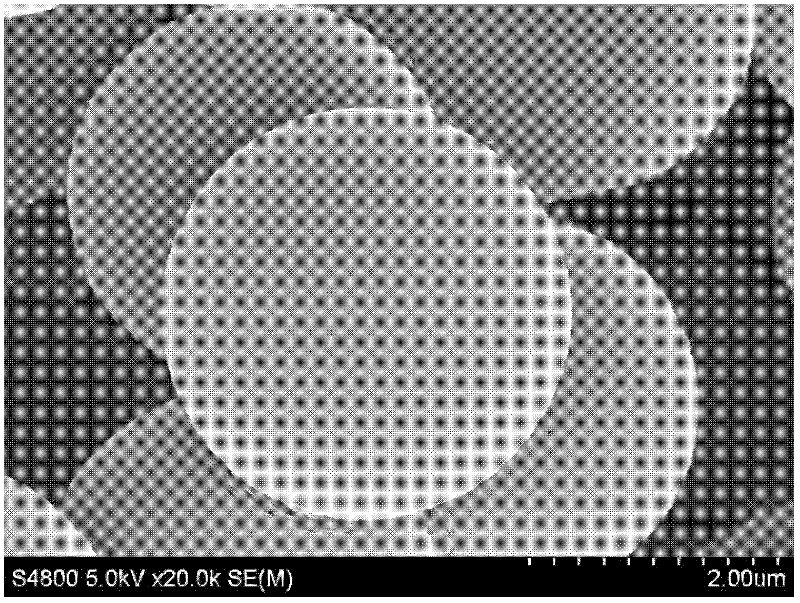

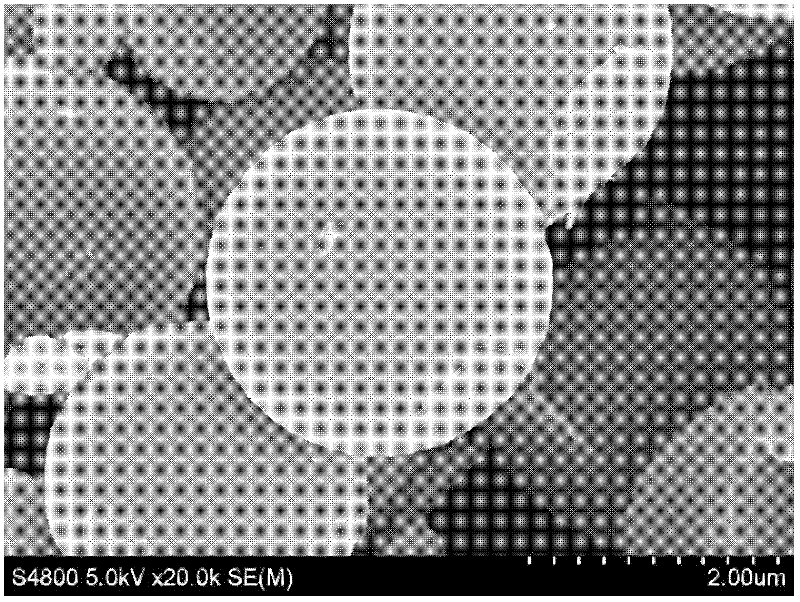

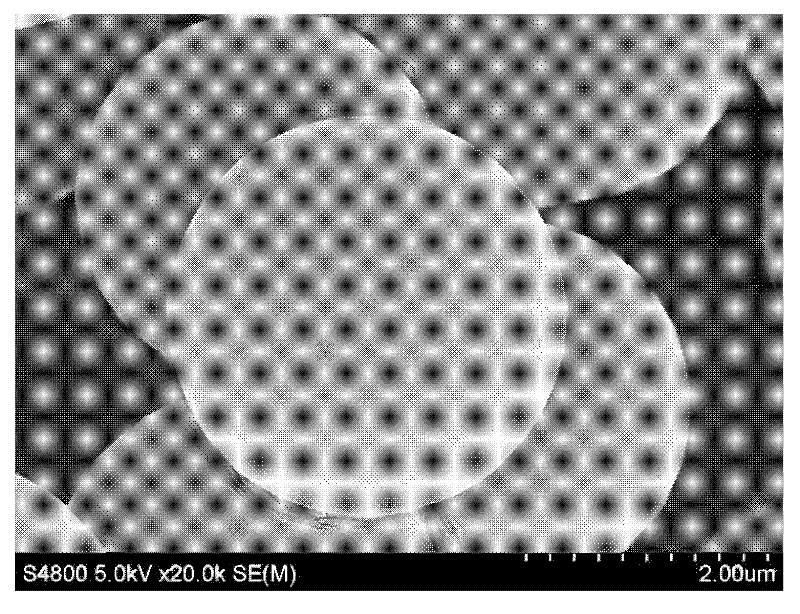

[0010] Specific embodiment one: the preparation method of phenolic resin microspheres in the present embodiment is carried out according to the following steps: step 1, by the mol ratio of resorcinol and phenol is 1: 0~9, resorcinol and formaldehyde The molar ratio of resorcinol and sodium carbonate is 1: 1.2~2.7, the molar ratio of resorcinol and sodium carbonate is 1:0~0.002, the molar ratio of resorcinol and sodium bicarbonate is 1:0~0.002 and resorcinol and sodium carbonate The molar ratio of water is 1: 16~60, mixing resorcinol, phenol, formaldehyde, sodium carbonate, sodium bicarbonate and water, stirring under the condition of 15~30r / min for 10~30min to obtain the reaction solution; step 2. Place the reaction solution in step 1 in an oil bath, stir at 20-30r / min while raising the temperature to 70-150°C and keep it for 4-6 hours to obtain a suspension of phenolic resin microspheres; step 3, the obtained in step 2 The suspension of the phenolic resin microspheres is suct...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of resorcinol to phenol in step 1 is 1:0.4-6. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the molar ratio of resorcinol to phenol in step 1 is 1:5. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com