Method for continuous production of high-concentration methylal

A technology of methylal and formaldehyde, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as difficult to handle, high loss of raw materials, and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

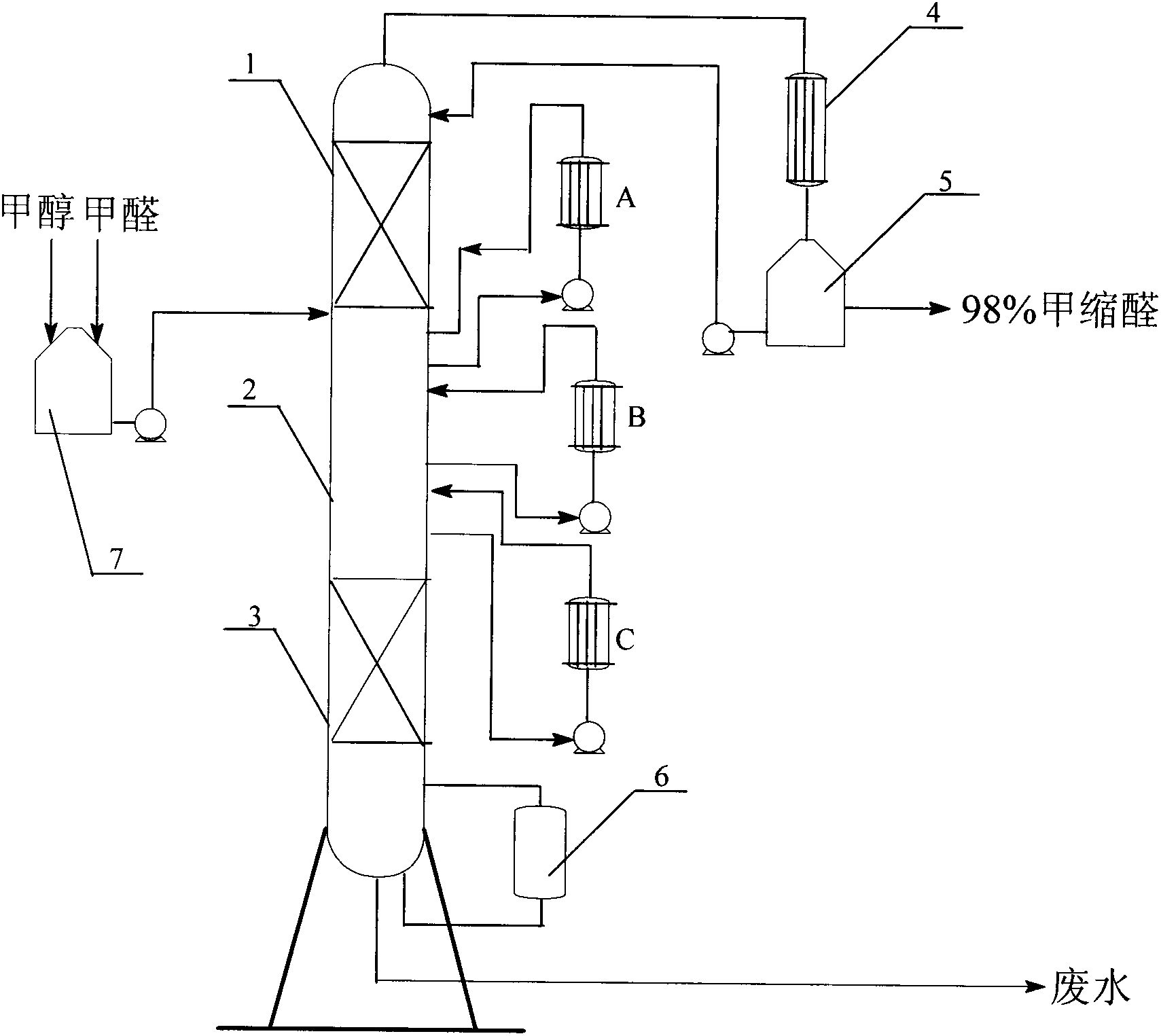

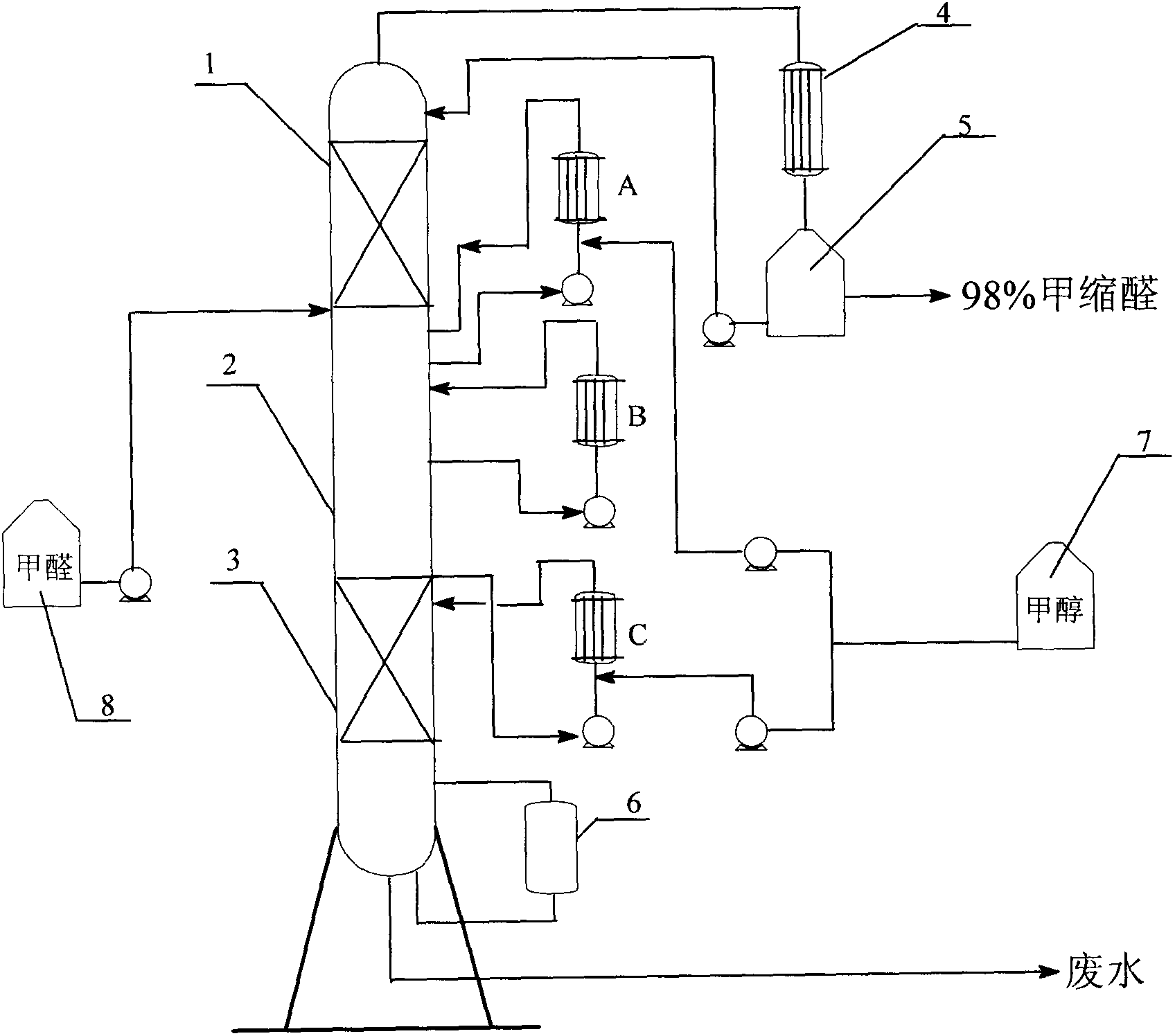

Method used

Image

Examples

Embodiment 1

[0045] Preheat 37% industrial formaldehyde solution to 40°C, and feed it into the formaldehyde feed port of the reactive distillation tower with a metering pump at a rate of 75.7Kg / h; preheat 99% industrial methanol to 40°C, and use a metering pump to The speed of / h is added to the methanol feed port at the entrance of the secondary reactor A, and at the same time, the metering pump is added to the methanol feed port of the secondary reactor C at a speed of 18.1Kg / h; the temperature of the top reflux section is controlled at 37 ° C, The control temperature of the tower kettle was 102°C, and the reflux ratio was 5:1.

Embodiment 2

[0047] Preheat 37% industrial formaldehyde solution to 40°C, and feed it into the formaldehyde feed port of the reactive distillation tower with a metering pump at a rate of 75.7Kg / h; preheat 99% industrial methanol to 40°C, and use a metering pump to The speed of / h is added to the methanol feed port at the entrance of the secondary reactor A, and at the same time, the metering pump is added to the methanol feed port of the secondary reactor C at a speed of 18.1Kg / h; the temperature of the top reflux section is controlled at 38 ° C, The control temperature of the tower kettle was 102°C, and the reflux ratio was 5:1.

Embodiment 3

[0049] Preheat 37% industrial formaldehyde solution to 40°C, and feed it into the formaldehyde feed port of the reactive distillation tower with a metering pump at a rate of 75.7Kg / h; preheat 99% industrial methanol to 40°C, and use a metering pump to The speed of / h is added to the methanol feed port at the entrance of the secondary reactor A, and at the same time, the metering pump is added to the methanol feed port of the secondary reactor C at a speed of 18.1Kg / h; the temperature of the top reflux section is controlled at 37 ° C, The control temperature of the tower kettle was 102°C, and the reflux ratio was 5:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com