Method for preparing water treatment phosphorus accumulation filler by sintering with household garbage incineration residues

A domestic waste incineration and water treatment technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., to save mineral resources, avoid secondary pollution, and improve phosphorus adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

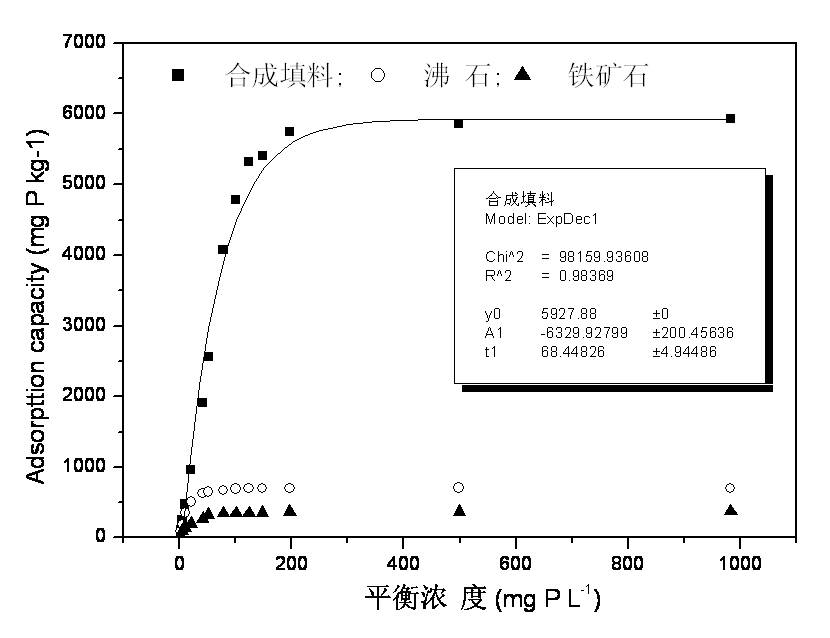

Embodiment 1

[0035] The raw material domestic waste incineration slag of this embodiment is sieved by a trommel sieve with an aperture of 80 mm, and the oxides of Ca, Fe and Al in the sieved domestic waste incineration slag are respectively represented by CaO, Fe 2 o 3 and Al 2 o 3 Calculated, the mass percentages are 7.1%, 6.6% and 15.6% respectively; the sieved domestic waste incineration slag and the clay with a plasticity index of 18.0 are mixed according to the mass percentage of 75% and 25%, and the mixture is machined into a particle size 15-30 mm filler; when sintering at high temperature, rapidly rise from room temperature to 400°C and keep for 10 minutes; then slowly and quickly raise the temperature to 1200°C, stabilize the final sintering temperature, keep for 10 minutes, and then get the water-treated phosphorus-polymer filler after cooling. Namely synthetic fillers.

[0036] Heavy metal leaching experiments show that the leaching concentrations of Cd, Zn, Cr, Cu, Pb, and N...

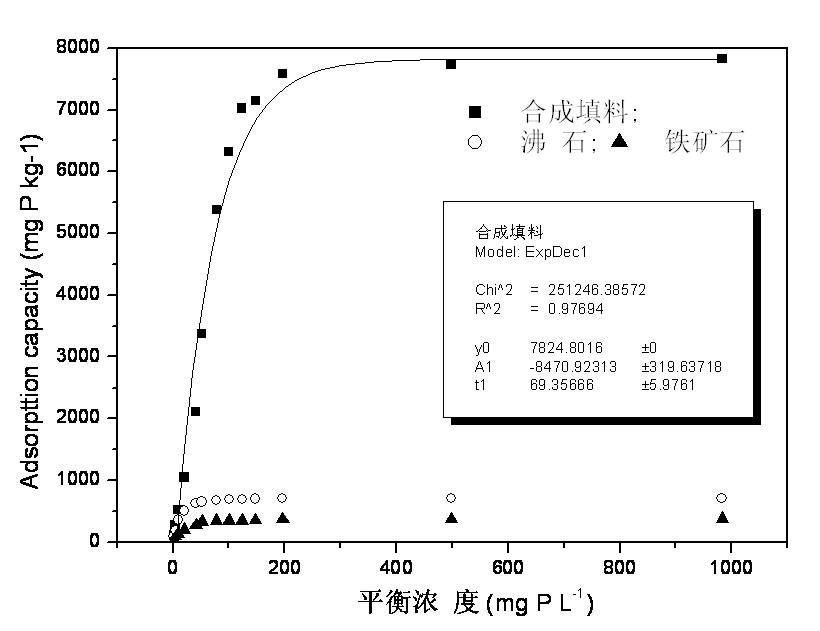

Embodiment 2

[0043] The raw material domestic waste incinerator slag of this embodiment is sieved by a trommel sieve with an aperture of 50 mm, and the oxides of Ca, Fe and Al in the sieved domestic waste incinerator slag are respectively represented by CaO, Fe 2 o 3 and Al 2 o 3 Calculated, the mass percentages are 10.8%, 8.0% and 14.8% respectively; the sieved domestic waste incineration slag and the clay with a plasticity index of 17.5 are mixed according to the mass percentage of 70% and 30%, and the mixture is machined into a particle size 5-25 mm filler; when sintering at high temperature, rapidly rise from room temperature to 420°C and keep for 8 minutes; then slowly and quickly raise the temperature to 900°C to stabilize the final sintering temperature and keep for 12 minutes, and after cooling, the water-treated phosphorus-polymer filler is obtained. That is, synthetic fillers.

[0044] Heavy metal leaching experiments show that the leaching concentrations of Cd, Zn, Cr, Cu, Pb...

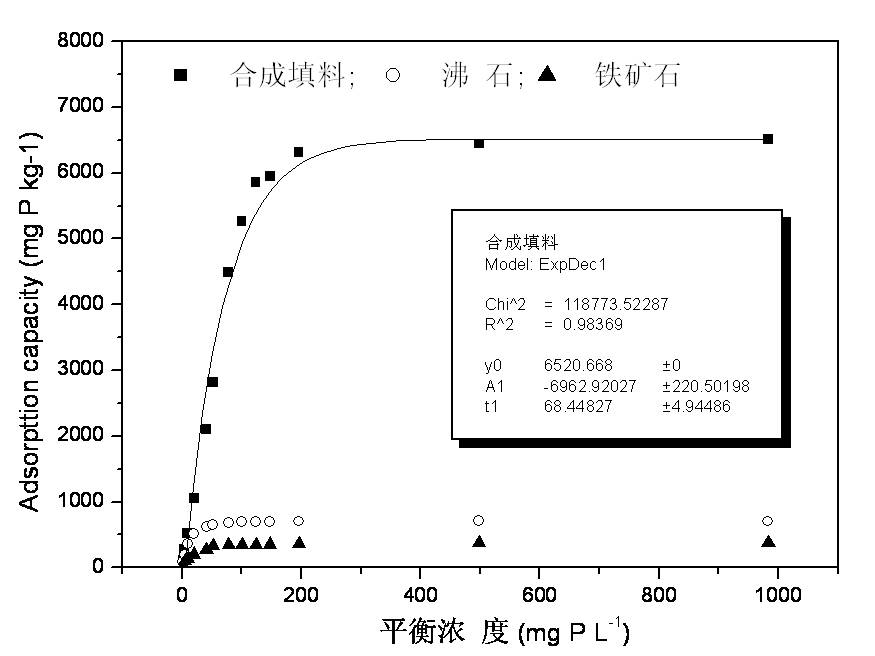

Embodiment 3

[0051] The raw material domestic waste incinerator slag of this embodiment is sieved by a trommel sieve with an aperture of 100 mm, and the oxides of Ca, Fe and Al in the sieved domestic waste incinerator slag are respectively represented by CaO, Fe 2 o 3 and Al 2 o 3 Calculated, the mass percentages are 7.3%, 6.6% and 16.1% respectively; the sieved domestic waste incineration slag and clay with a plasticity index of 18.3 are mixed according to the mass percentages of 65% and 35%, and the mixture is machined into a particle size 30~50mm filler; when sintering at high temperature, rapidly rise from room temperature to 380°C and keep for 12 minutes; then slowly and quickly raise the temperature to 1400°C to stabilize the final sintering temperature and keep for 8 minutes; after cooling, the water-treated phosphorus-polymer filler is obtained. That is, synthetic fillers.

[0052] Heavy metal leaching experiments show that the leaching concentrations of Cd, Zn, Cr, Cu, Pb, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com