Application of straw biomass charcoal in processing electroplating wastewater

A biochar and electroplating wastewater technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult disposal and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

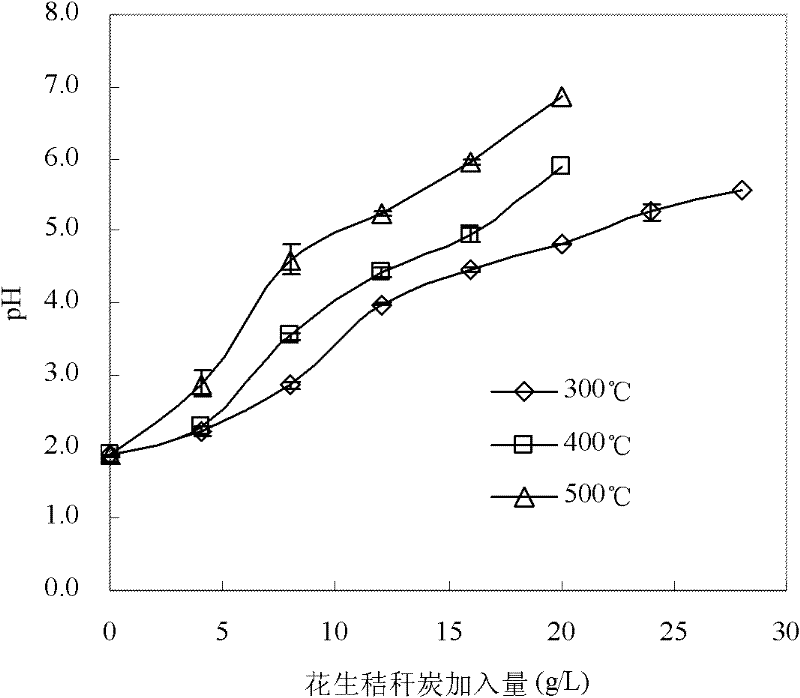

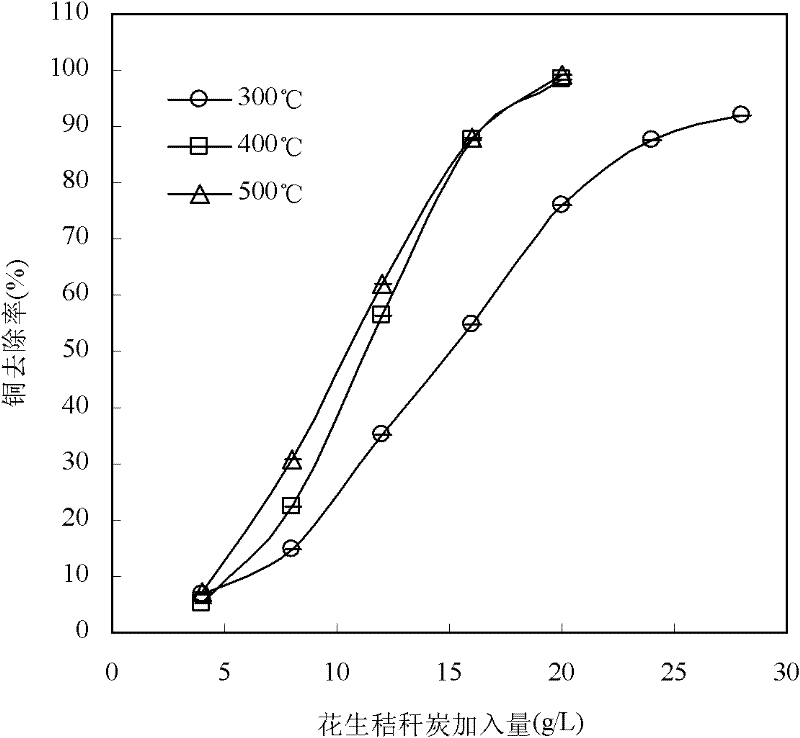

[0021] Effects of biochar prepared at different temperatures on acid and copper removal from wastewater.

[0022] Preparation of biochar from air-dried peanut stalks under anaerobic conditions of 300°C, 400°C, and 500°C [see utility model patent: 201020683459.3 and references: Yuan, J.H., Xu, R.K., Zhang, H. 2011. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresource Technology 102: 3488-3497], collected the pickling wastewater produced by electroplating copper in an electroplating factory in Nanjing. Add biochar to wastewater at a ratio of 4g / L-28g / L, mix straw biochar that has passed through a 60-mesh sieve with acid wastewater in the reaction tank, stir continuously for 2 hours, let stand for 8 hours, and then stir for 0.5 After standing still for 1.5 hours, the mixed solution was separated from the biochar through a sand filter device, and the clear liquid was discharged. The pH of the solution and the copper content in the ...

Embodiment 2

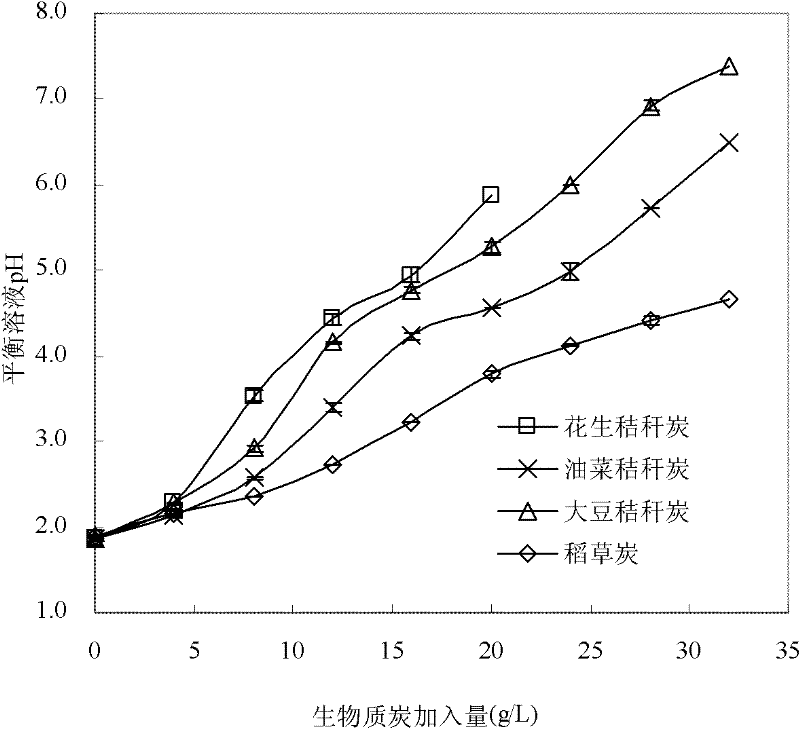

[0025] Comparison of removal of acid and copper in electroplating wastewater by peanut straw charcoal, soybean straw charcoal, rapeseed straw charcoal and rice straw charcoal.

[0026] According to the method in Example 1, air-dried peanut straw, soybean straw, rapeseed straw and rice straw were subjected to anaerobic pyrolysis at 400° C. to prepare corresponding biochar. Mix the straw biochar passed through a 60-mesh sieve with the electroplating wastewater in Example 1 at a ratio of 4g / L to 32g / L, stir continuously for 2 hours, let stand for 8 hours, stir for another 0.5 hours, and let stand for 1.5 hours , the mixed liquid was separated from the biochar by a sand filter device, the clear liquid was discharged, the pH and copper content of the filtrate were measured, and the effect of removing acid and copper by the straw biochar at the same time was investigated. image 3 It is the pH of the filtrate after the reaction of four kinds of straw biochar and electroplating waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com