Moderate temperature pressure swing adsorption method for CO2, H2S and H2 mixed gas separation

A technology of pressure swing adsorption and mixed gas, which is applied in the field of clean energy, can solve the problems of increasing gas drying links, waste of raw gas, and complicated operation, and achieve the goal of improving gas processing capacity, reducing system heat exchange equipment, and reducing system complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

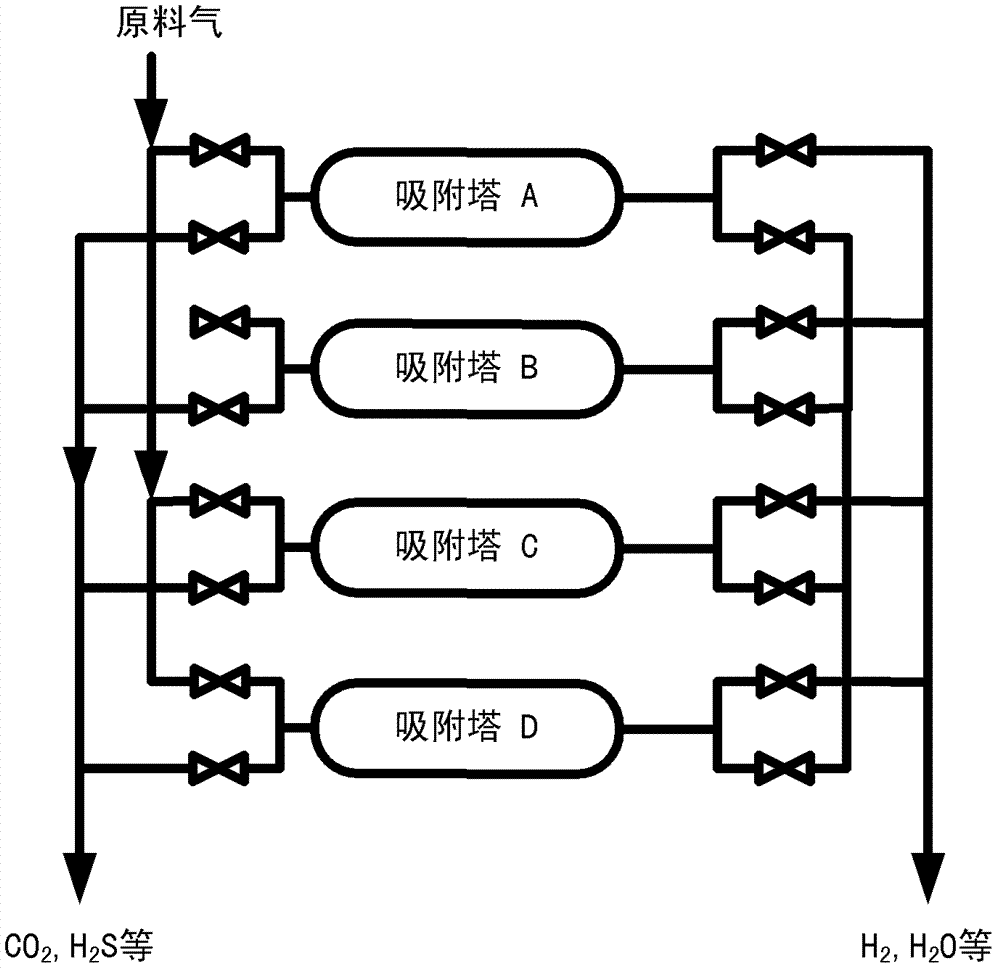

[0036] This example adopts four adsorption tower configurations, see figure 1 . The raw material gas is transported from the raw material gas buffer tank through the insulation pipeline, through the high temperature resistant program-controlled valve, to the adsorption tower; the pressure swing adsorption is composed of 4 adsorption towers; each adsorption tower needs to experience adsorption and 2 times of pressure drop 1. Forward pressure release, reverse pressure release, flushing, 2 equal pressure rises, and final flushing, a total of 9 steps.

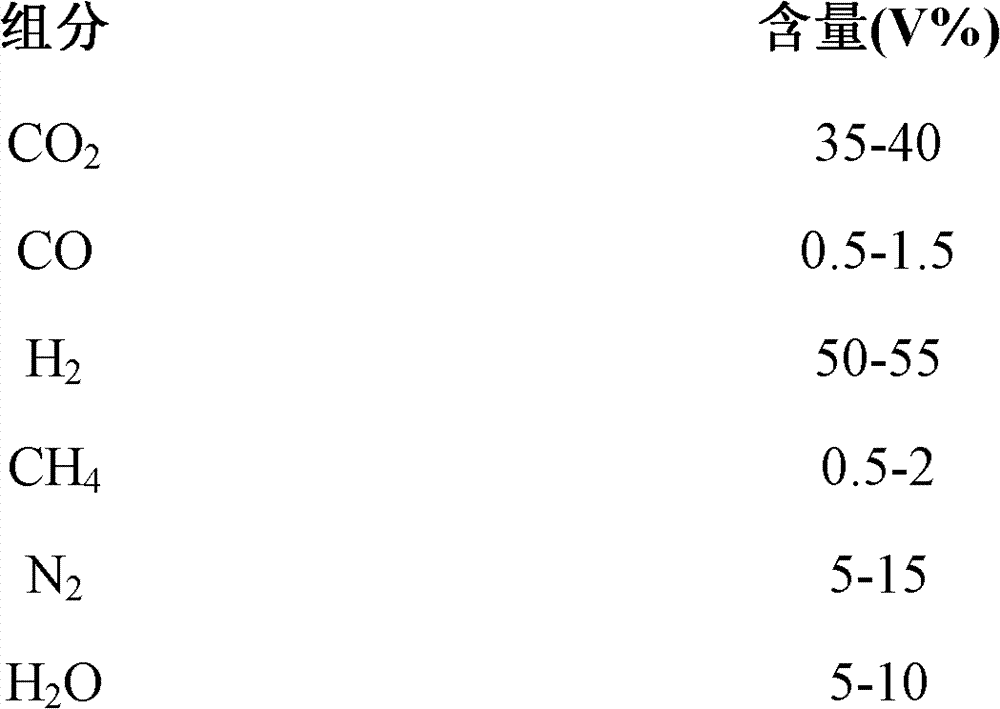

[0037] Raw gas is the outlet gas after the typical coal gasification gas passes through the shift reactor, and its components are:

[0038]

[0039]

[0040] Raw gas pressure: 2.7MPa

[0041] Raw gas temperature: 200-350°C,

[0042] The pressure of the four adsorption towers is adjustable,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com