Intermediate temperate pressure swing adsorption method for using bifunctional adsorbent in adsorption enhanced type vapor reforming and water-vapor transformation reactions

A technology of steam reforming and water-gas shift, applied in chemical instruments and methods, using solid contact hydrogen separation, inorganic chemistry, etc., can solve the problems of increased catalyst and adsorbent consumption, complicated operation, high energy consumption, etc., to achieve The effect of improving gas processing capacity, reducing system complexity, and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

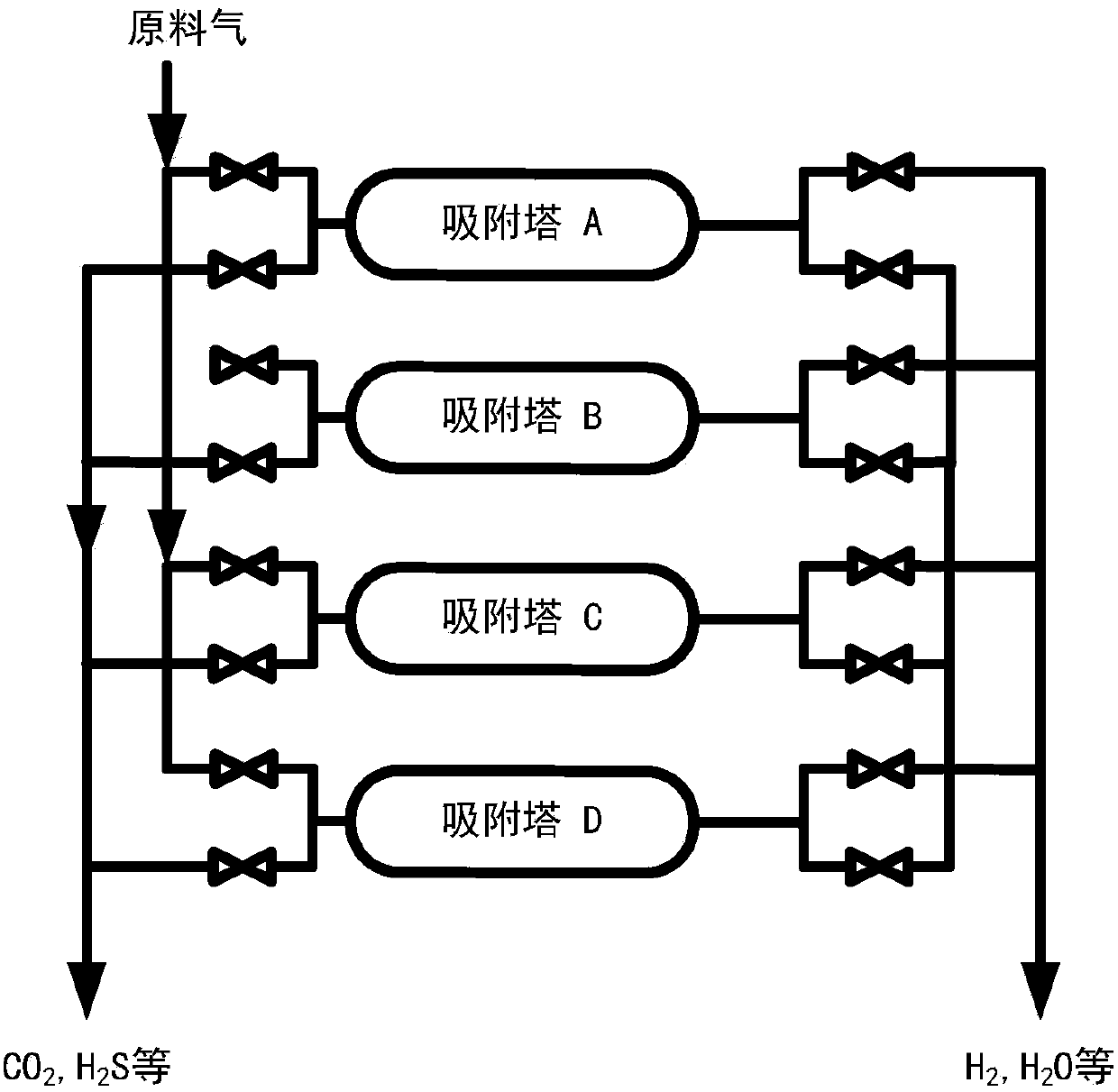

[0049] This example adopts four adsorption tower configurations, see figure 1 shown. The raw material gas is transported from the raw material gas buffer tank through the insulation pipeline, through the high temperature resistant program-controlled valve, to the adsorption tower; Steps of pressure release in direction, reverse pressure release, flushing, 2 pressure equalizations and final charge.

[0050] The composition of raw gas is as follows:

[0051]

[0052] Raw gas pressure: 5MPa

[0053] Raw gas temperature: 400-450°C

[0054] The pressures of the four adsorption towers are adjustable, and the adsorption towers are filled with adsorbents, and the adsorbents are composed of K 2 CO 3 Modified Mg-Al hydrotalcite compounded with molecular sieves and activated carbon, K 2 CO 3 The modified Mg-Al hydrotalcite accounts for 50% of the total mass of the adsorbent.

[0055] After the feed gas enters the adsorption tower, it undergoes steam reforming and water-gas shi...

Embodiment 2

[0081] This example uses a four-tower configuration, such as figure 1 shown. The raw material gas is transported from the raw material gas buffer tank through the insulated pipeline, through the high temperature resistant program-controlled valve, to the adsorption tower.

[0082] The composition of raw gas is as follows:

[0083]

[0084] Raw gas pressure: 3MPa

[0085] Raw gas temperature: 200-300°C

[0086] The pressure of the four adsorption towers is adjustable, and the adsorption tower is equipped with an adsorbent, which is composed of Na-modified Zn-Al hydrotalcite, molecular sieve, activated carbon, NaNO 3 The modified Zn-Al hydrotalcite accounts for 70% of the total mass of the adsorbent.

[0087] The specific operation steps are the same as in Example 1, and the changes are as follows: when the adsorption capacity of the adsorbent reaches 60% of the saturated adsorption capacity, the adsorption towers are automatically switched, and the previously working ads...

Embodiment 3

[0090] This example adopts 2 adsorption tower configurations, such as figure 2 shown. The raw material gas is transported from the raw material gas buffer tank through the insulated pipeline, through the high temperature resistant program-controlled valve, to the adsorption tower. The steps experienced by each adsorption tower include four steps of pressure charging, adsorption, pressure release and purging.

[0091] The composition of raw gas is as follows:

[0092]

[0093] Raw gas pressure: 3MPa

[0094] Raw gas temperature: 200-300°C

[0095] The pressure of the two adsorption towers is adjustable, and the adsorption tower is equipped with adsorbent, and the adsorbent is made of Na 2 CO 3 The modified Mg-Al hydrotalcite is composited with activated carbon, and the Na-modified Mg-Al hydrotalcite accounts for 20% of the total mass of the adsorbent.

[0096] The specific operation steps are the same as in Example 1, and the changes are as follows: when the adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com