Stable gas membrane and method used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater

An organic amine and gaseous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult to obtain by-product ammonium salt solution, low service life of components, wetting leakage, etc., to eliminate Effects of mass transfer resistance, fluid flow stability, and avoidance of backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

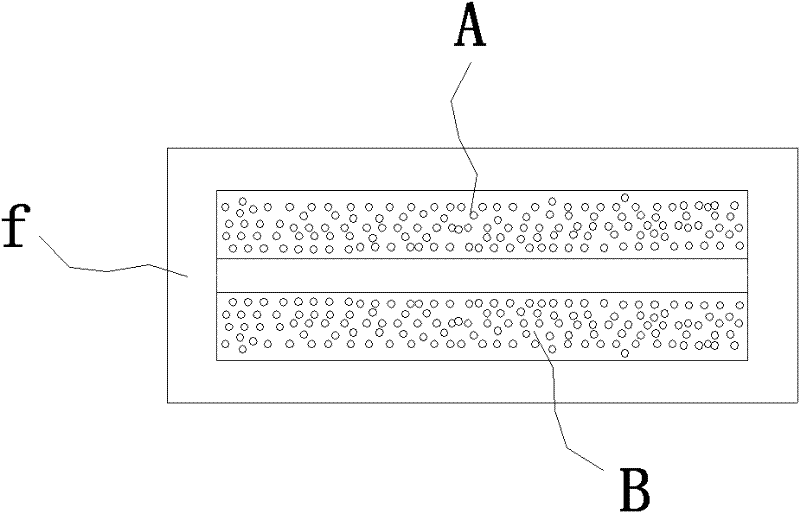

[0044] A stable gaseous membrane device made of polypropylene hollow fiber microporous hydrophobic membrane was used to treat dilute ammonia solution. The effective membrane area based on the inner diameter of the hollow fiber membrane A that feed liquid enters is 5.10m 2 , The parameters of the membrane are: outer diameter 0.48mm, inner diameter 0.38mm, average pore diameter 0.02μm, porosity 40%.

[0045] Feed liquid: Ammonia solution: Influent ammonia concentration C 0 =5018ppm, flow rate Q=20L / h, pH=12.3, temperature T=30°C;

[0046] Absorbent: H 2 SO 4 The initial concentration is 5%, the flow rate is 10L / h, and the temperature is 30°C.

[0047] Experimental results: the concentration of ammonia nitrogen in the effluent is 45ppm, the removal rate of ammonia nitrogen is 99.1%, and the mass transfer coefficient is 5.14×10 -6 m / s. After repeated use in many experiments, the concentration of ammonium sulfate in the absorption liquid can reach 28.5%.

[0048] After one m...

Embodiment 2

[0054] The stable gaseous membrane module and its parameters are the same as in Example 1;

[0055] Feed liquid to be treated: imported ammonia nitrogen concentration C 0 =3018ppm, NaCl concentration is 15%, flow Q=20L / h, pH>12, temperature T=30°C;

[0056] Absorbing liquid: sulfuric acid solution with an initial concentration of 5%, flow rate 10L / h, temperature 20°C

[0057] Experimental results: the concentration of ammonia nitrogen in the effluent is 10ppm, the removal rate of ammonia nitrogen is 99.8%, and the mass transfer coefficient is 6.77×10 -6 m / s.

Embodiment 3

[0062] A self-made polypropylene stabilized gaseous membrane module was used to treat solutions containing ammonia and isopropanol. The effective membrane area based on the inner diameter of the hollow fiber membrane A entering the feed liquid is 1.45m 2, The parameters of the membrane are: outer diameter 0.48mm, inner diameter 0.38mm, average pore diameter 0.02μm, porosity 40%.

[0063] Feed liquid: the ammonia content is 5.015% (50150ppm), the isopropanol content is 7.28%, the flow rate is 20L / h, the initial temperature T1=30°C, and the cycle operation;

[0064] Absorbing solution: 15% sulfuric acid solution, flow rate 25L / h, initial temperature T2=42°C (caused by sulfuric acid dilution heat), cycle operation, when the pH of the absorbing solution flowing out of outlet 4>2, add more to the acid absorbing solution storage tank 98% concentrated sulfuric acid.

[0065] Experimental results:

[0066] The concentration of ammonia nitrogen in the treated feed liquid or wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com