Low-speed half direct-driven marine current energy power generation device

A power generation device, semi-direct drive technology, applied in ocean energy power generation, renewable energy power generation, hydropower generation, etc., can solve the problems of complex design of pitch control mechanism, shortening the life of the main shaft, increasing the cantilever load of the hub main shaft, etc. Effect of small hindrance, simplification of execution structure, and reduction of spindle load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

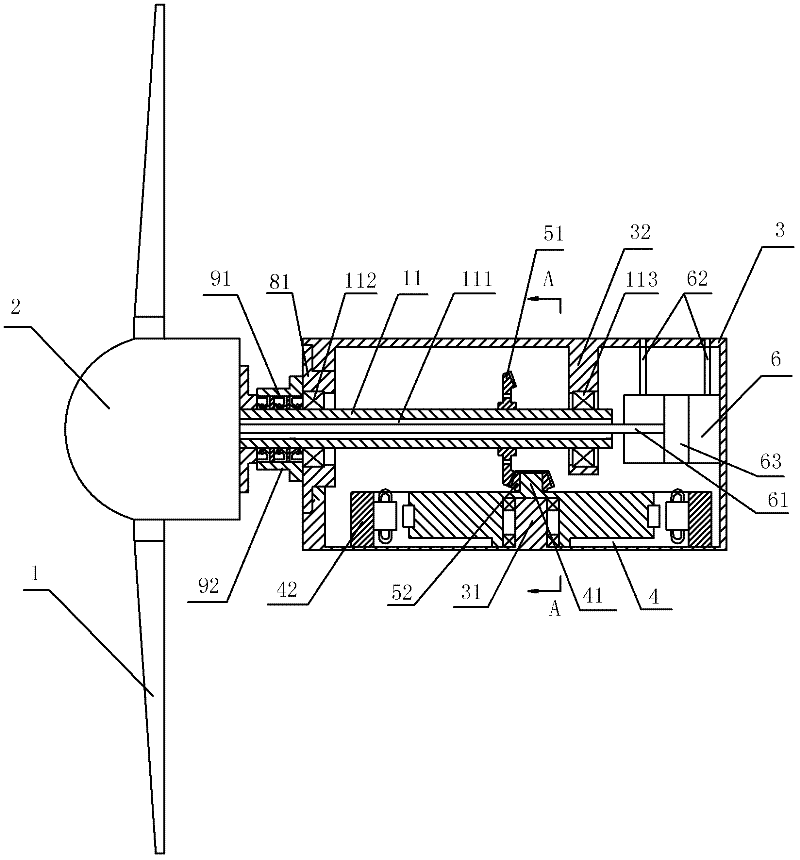

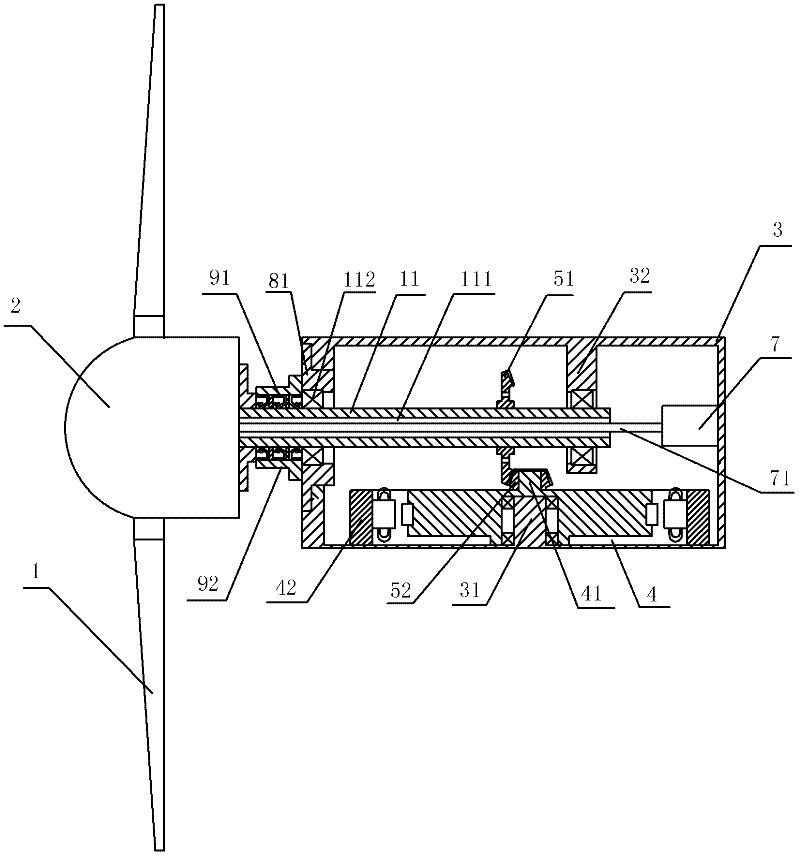

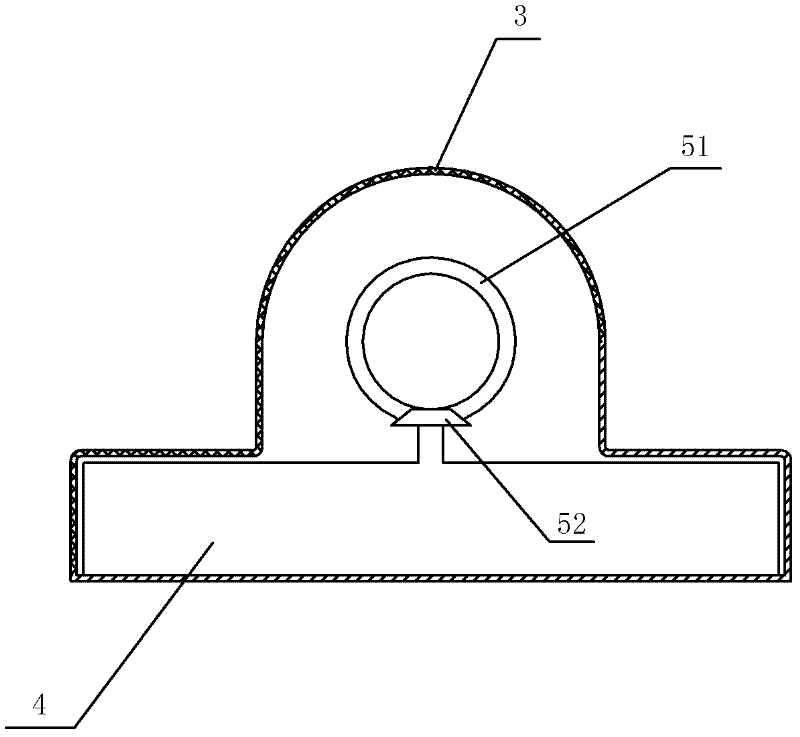

[0022] Refer to attached figure 1 and image 3 . figure 1 and image 3 Shown in is the first embodiment of the present invention, a low-speed semi-direct-drive ocean current energy generating device, including blade 1, hub 2, nacelle 3 and pitch-changing mechanism, blade 1 is installed on hub 2, and pitch The actuator of the mechanism is arranged in the hub 2 , and the driving mechanism of the pitch control mechanism is arranged in the nacelle 3 .

[0023] The generator 4 is located inside the nacelle 3, the stator 42 of the generator 4 is fixed on the inner bottom surface of the nacelle 3, the rotor 41 of the generator 4 is sleeved on the column 31 on the inner bottom surface of the nacelle 3, and the rotor 41 of the generator 4 has an axis The direction is the same as the axial direction of the column 31 , the rotor 41 of the generator 4 can rotate around the column 31 in the circumferential direction, and the axial direction of the rotor 41 of the generator 4 is perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com