Ultralow temperature polishing machine

A polishing machine, ultra-low temperature technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that are difficult to avoid processing metamorphic layer and sub-surface layer damage, surface scratches and internal stress, etc. Achieve the effects of convenient operation, less environmental pollution and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

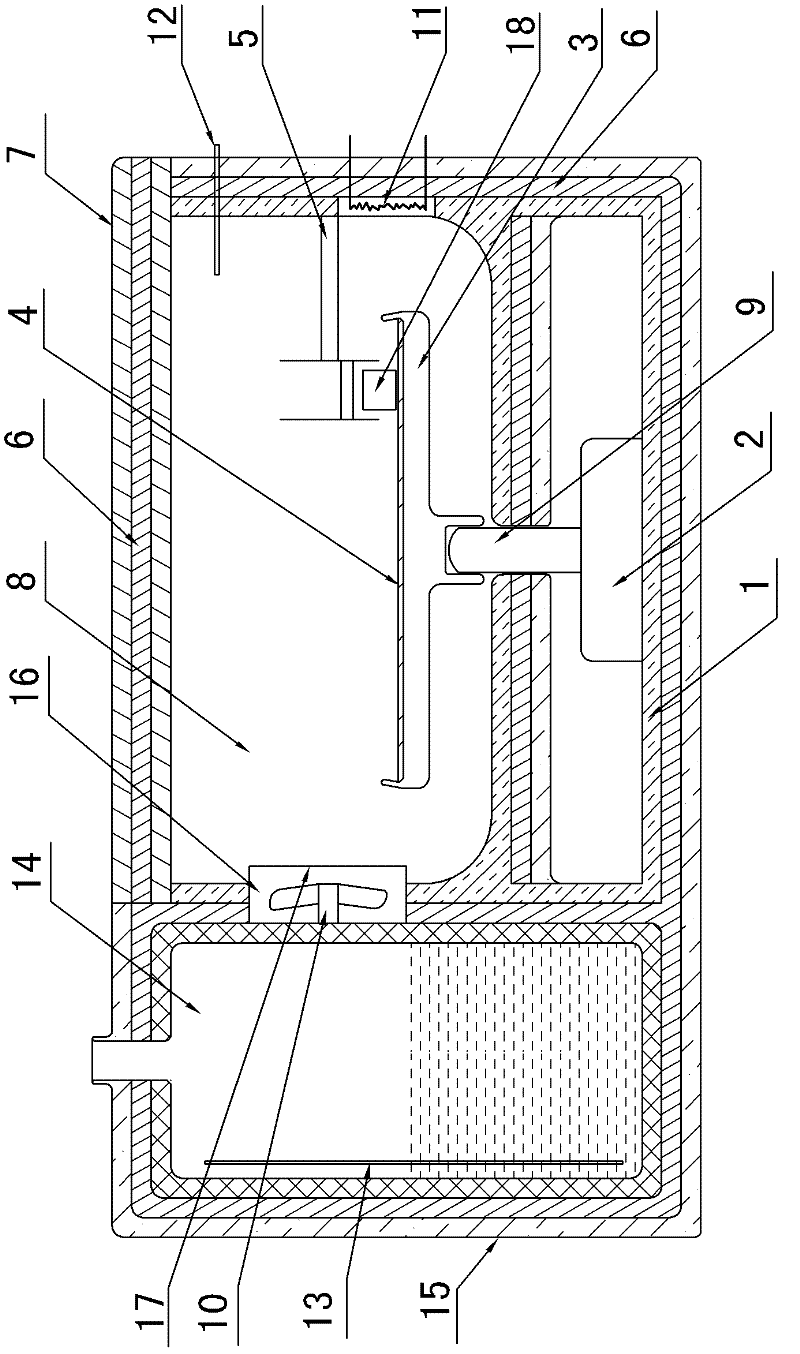

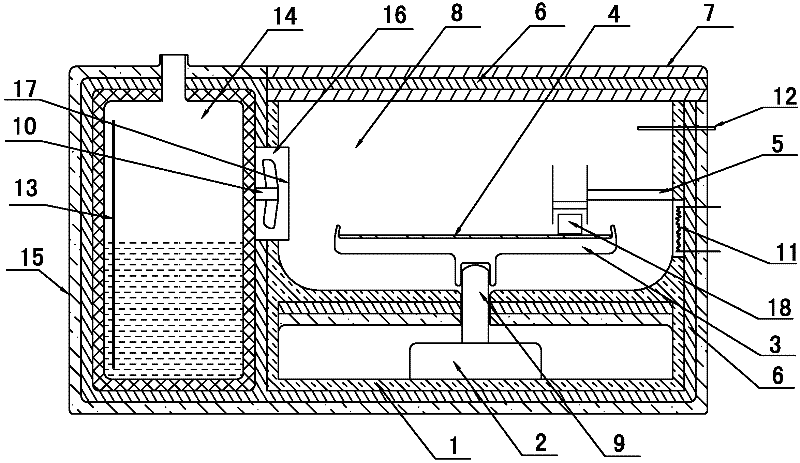

[0017] exist figure 1 In the shown embodiment, it includes a metal shell 1 with an open top, a motor 2, a polishing disc 3 with a conical sleeve, a polishing pad 4, a sample holder 5 and a top cover 7 provided with an insulating layer 6, wherein The polishing pad 4 is made of ice, the motor 2 is fixed at the bottom of the metal shell, the polishing disc 3 with the taper sleeve is located in the working area 8, and is fixedly installed on the output shaft 9 of the motor 2, and the sample holder 5 is set On the inner wall of the metal shell 1 and on the polishing pad 4, the top cover 7 is fastened on the metal shell 1; a fan 10, an electric heater 11, a temperature sensor 12, a liquid level sensor 13 and an insulating layer are added 6, the liquid nitrogen metal container 14, wherein the liquid nitrogen metal container 14 is installed on the side wall of the metal shell 1, and the other outer walls of the liquid nitrogen metal container 14 away from the metal shell 1 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com