Preparation method of supported catalyst and supported catalyst

A supported catalyst and co-catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic efficiency and easy poisoning of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

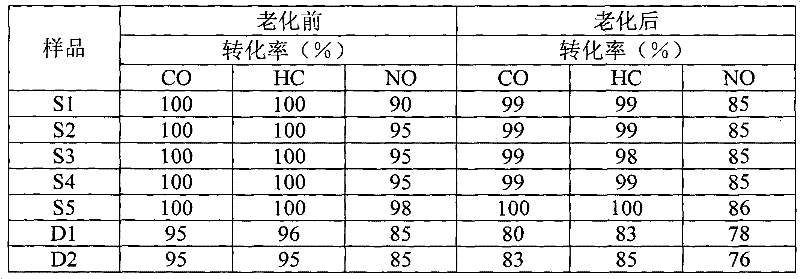

Examples

preparation example Construction

[0014] The preparation method of the supported catalyst disclosed by the invention comprises:

[0015] a. Impregnating the adsorbent with an active component solution to obtain an active adsorbent; wherein, the adsorbent is one or more of activated carbon, mesoporous carbon, and amorphous carbon;

[0016] b. Mixing the active adsorbent and the carrier in the presence of water to form a slurry; the carrier contains alumina and a cocatalyst, with or without active metal nitrates and binders;

[0017] c. Coating the slurry on the honeycomb ceramic substrate, drying, and firing in an oxidative atmosphere to ablate and remove the adsorbent to obtain a supported catalyst.

[0018] According to the present invention, the active component solution used is a solution of various active substances used for catalysis in the prior art, for example, the nitrates of noble metal active substances Pt, Pd, Rh in the field of automobile exhaust catalysis, etc., specifically in various fields Th...

Embodiment 1

[0044] This example is used to illustrate the preparation method of the supported catalyst and the supported catalyst provided by the present invention.

[0045] At 55 parts by weight, the pH value is 2, and concentration is the spherical activated carbon (D 50 3um, the specific surface is 1500m 2 / g, the ablation temperature is 600°C), soaking for 120min.

[0046] Add 25 parts by weight of alumina (Zibo Boyang Chemical Co., Ltd. company, average pore diameter is 20nm, average pore volume is 0.5mL / g), 15 parts by weight of cerium-zirconium composite oxide (Zibo Huaqing powder material Technology Co., Ltd., the average pore diameter is 19.4nm, and the average pore volume is 0.21mL / g), and then the above mixed system is ball milled in a ball mill at a speed of 200r / min for 4h, and then dried at 90°C for 4h to obtain a slurry.

[0047] The slurry was adsorbed on a cordierite honeycomb ceramic substrate (a Φ96×125 mm cylindrical cordierite honeycomb ceramic substrate produced by...

Embodiment 2

[0049] This example is used to illustrate the preparation method of the supported catalyst and the supported catalyst provided by the present invention.

[0050] At 55 parts by weight, the pH value is 4, and in the active ingredient solution (concentration is the palladium nitrate of 1.3wt%, concentration is the rhodium nitrate of 0.2wt%), the amorphous carbon (specific surface is 500m2) of 5 parts by weight is added 2 / g, the ablation temperature is 600°C), soaked for 150min.

[0051] Add 14 parts by weight of alumina (Zibo Boyang Chemical Co., Ltd. company, average pore diameter is 20nm, average pore volume is 0.5mL / g), 24 parts by weight of cerium-zirconium-lanthanum composite oxide (Zibo Huaqing powder Body Material Technology Co., Ltd., the average pore diameter is 19.4nm, and the average pore volume is 0.21mL / g), 1 part by weight of yttrium nitrate (Zibo Huaqing Powder Material Technology Co., Ltd.), 1 part by weight of barium nitrate (Zibo Huaqing Powder Material Techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com