Method and system for efficiently controlling mercury pollution of coal-fired power plant at low cost

A technology for coal-fired power plants and control methods, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as low halogen content, no removal of elemental mercury, and poor oxidation effect, and achieve investment costs and operation The effect of low cost, efficient mercury pollution control, and simple dosing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

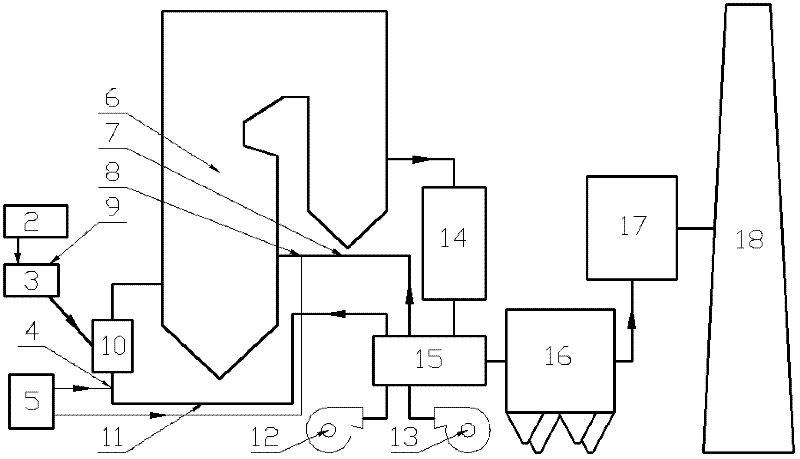

[0033] Such as figure 1As shown, a high-efficiency and low-cost coal-fired power plant mercury pollution control system includes a secondary air hot air pipeline 7 communicated with the boiler body 6, the secondary air hot air pipeline 7 communicates with the air preheater 15, and also includes a The primary air hot air pipeline 11 connected to the heater 15, the primary air hot air pipeline 11 communicates with the coal mill 10, the coal mill 10 communicates with the boiler body 6, and the coal conveying system 2 communicates with the coal mill 10 through the coal feeder 3 for Coal is supplied to the coal mill 10, and the air preheater 15 is connected with a primary fan 12 and a secondary fan 13, which supply air to the primary air hot air pipeline 11 and the secondary air hot air pipeline 7 respectively, and the outlet of the boiler body 6 and the air preheater A denitrification system 14 is set between the heaters 15, and the air preheater 15 is connected to the dust remove...

Embodiment 2

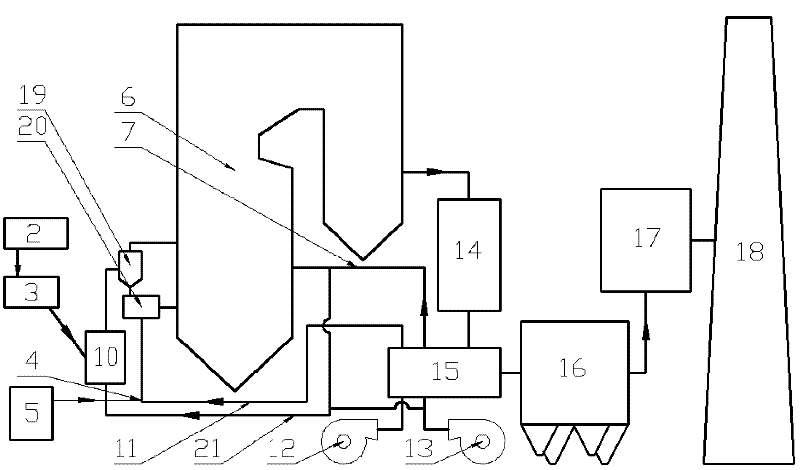

[0038] Such as figure 2 As shown, a high-efficiency and low-cost coal-fired power plant mercury pollution control system includes a secondary air hot air pipeline 7 communicated with the boiler body 6, the secondary air hot air pipeline 7 communicates with the air preheater 15, and also includes a The primary air hot air pipeline 11 connected to the heater 15, the primary air hot air pipeline 11 communicates with the coal mill 10, the coal mill 10 communicates with the boiler body 6, and the coal conveying system 2 communicates with the coal mill 10 through the coal feeder 3 for Coal is supplied to the coal mill 10, and the air preheater 15 is connected with a primary fan 12 and a secondary fan 13, which supply air to the primary air hot air pipeline 11 and the secondary air hot air pipeline 7 respectively, and the outlet of the boiler body 6 and the air preheater A denitrification system 14 is installed between the heaters 15, and the air preheater 15 is connected to the dus...

Embodiment 3

[0043] Such as image 3 As shown, a high-efficiency and low-cost coal-fired power plant mercury pollution control system includes a secondary air hot air pipeline 7 communicated with the boiler body 6, the secondary air hot air pipeline 7 communicates with the air preheater 15, and also includes a The secondary air branch pipe 21 connected to the heater 15 and the secondary air hot air pipeline 7, the secondary air branch pipe 21 is connected to the coal mill 10, the coal mill 10 is connected to the boiler body 6, and the coal conveying system 2 is connected to the coal feeder 3 The coal mill 10 is used to supply coal to the coal mill 10. The coal mill 10 communicates with the coal powder bin 20 through the pulverized coal separator 19. The pulverized coal bin 20 communicates with the boiler body 6. The pulverized coal bin 20 passes through the primary air hot air The pipeline 11 communicates with the air preheater 15, and the air preheater 15 is connected with a primary fan 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com