Method and structure for testing metal-oxide-semiconductor field-effect transistor (MOSFET)

A field-effect transistor and test structure technology, which is applied in the direction of single semiconductor device testing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of electrical characteristic parameters and mismatch parameter errors, reduce the accuracy of testing MOSFETs, etc., and achieve To avoid the effect of parasitic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

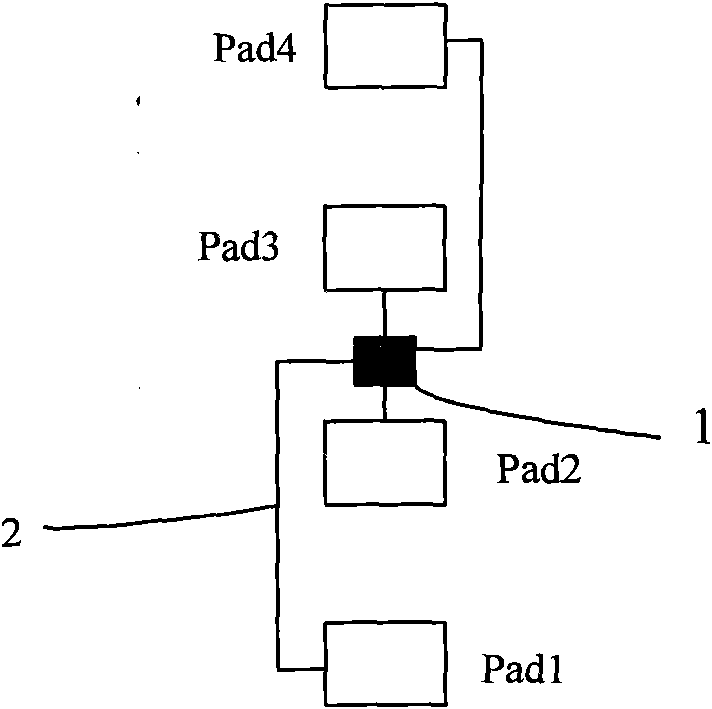

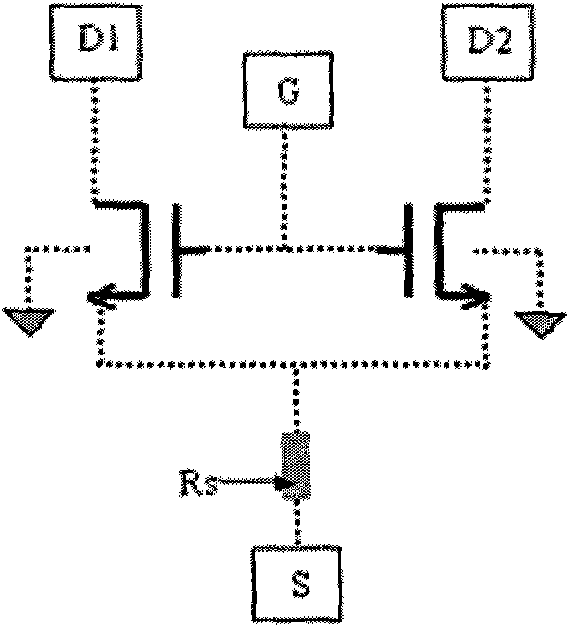

[0028] It can be seen from the prior art that the reason for the inaccuracy of the MOSFET test is because figure 1 The test structure shown has a parasitic resistance Rs on the metal lead between the MOSFET source pad and the MOSFET under test, so the Idsat of the tested MOSFET is smaller than the actual one, and the threshold voltage is larger than the actual one. Therefore, the electrical characteristic parameters and mismatch parameters of the finally obtained MOSFET test are inaccurate. In order to overcome this defect, the present invention resets the test structure of the MOSFET, which avoids the parasitic resistance on the metal lead between the source of the MOSFET and the MOSFET of the device under test.

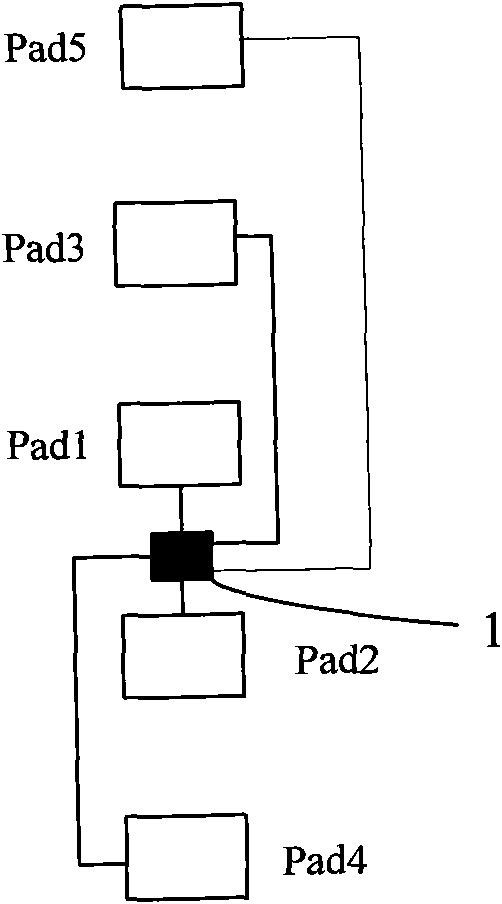

[0029] Further, the test structure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com