Package structures

A technology of packaging structure and packaging materials, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of poor heat dissipation effect of copper clips, achieve good heat dissipation, improve component efficiency, and reduce package size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

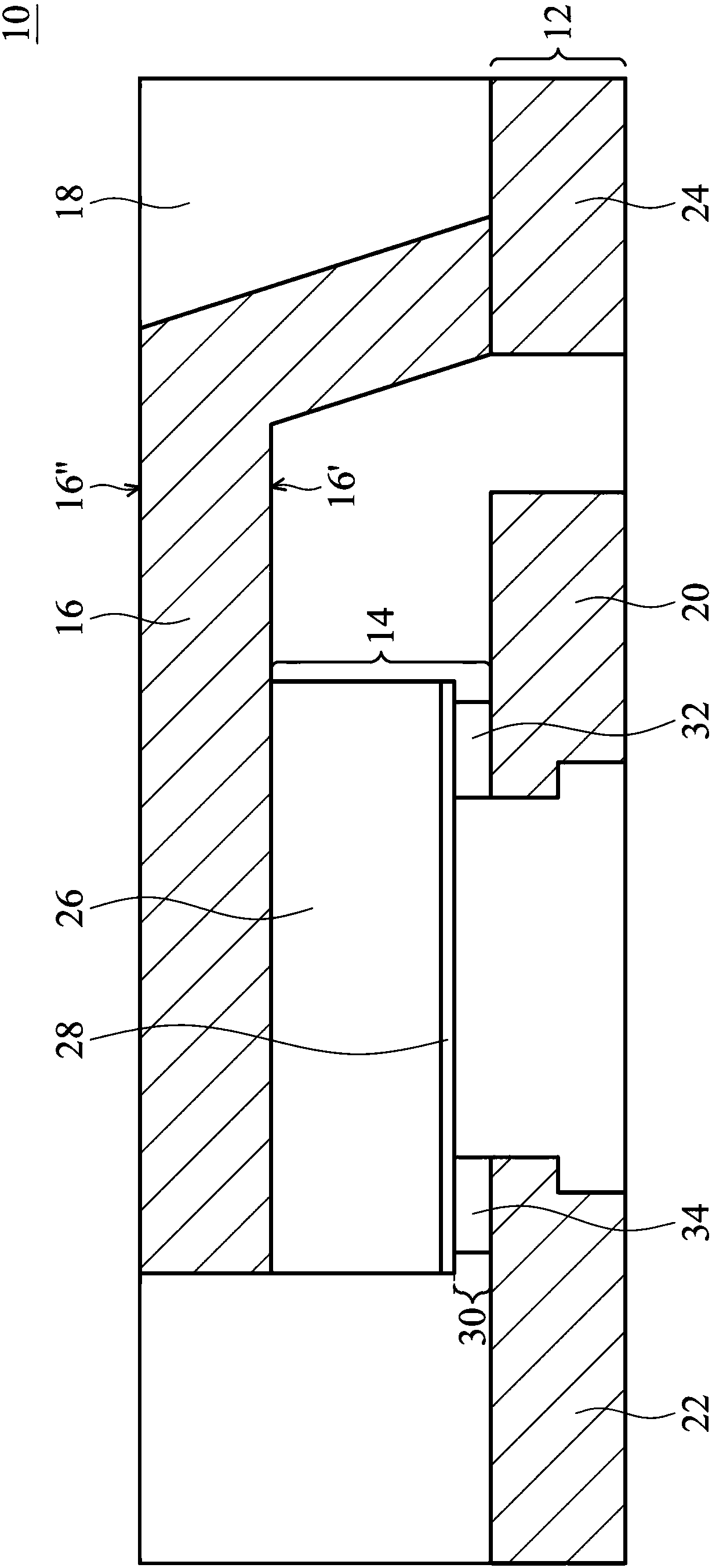

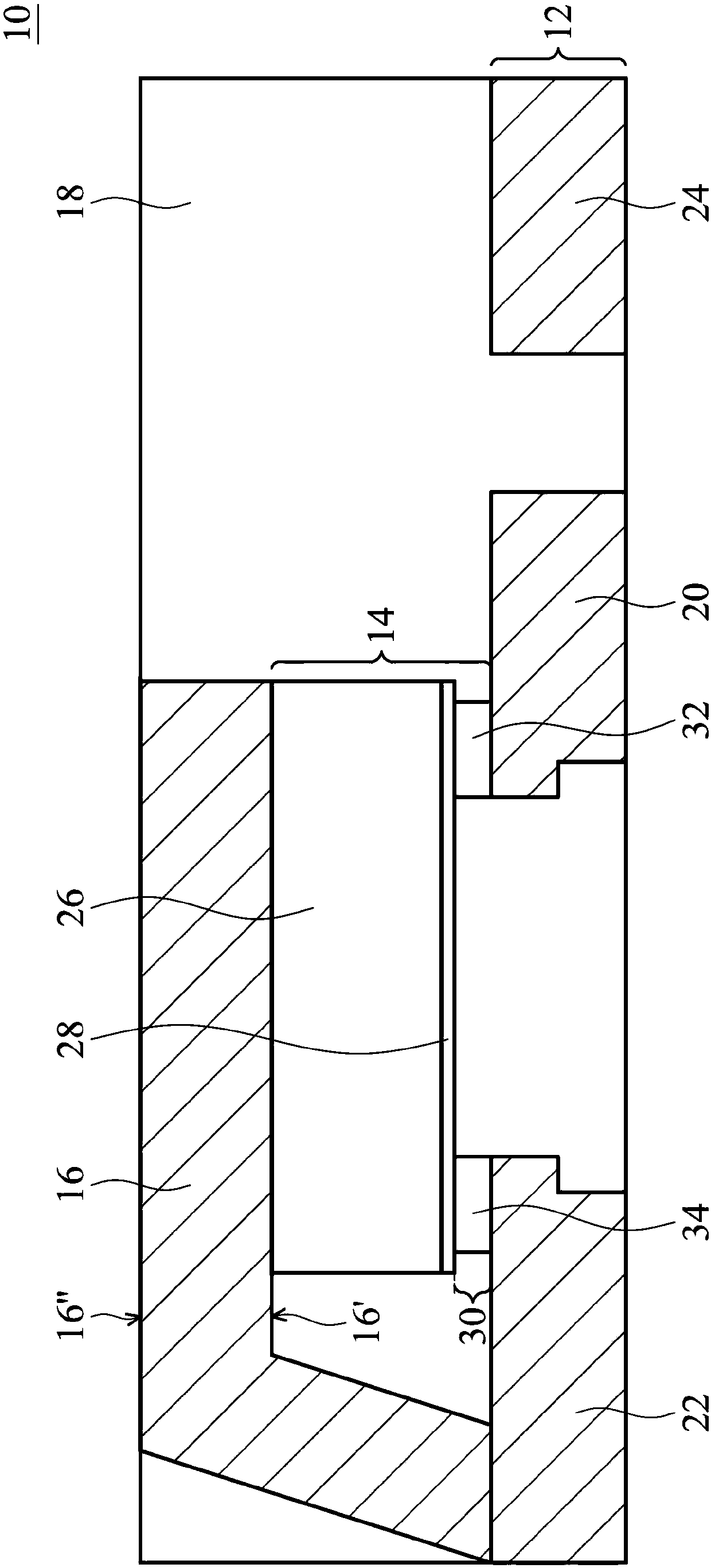

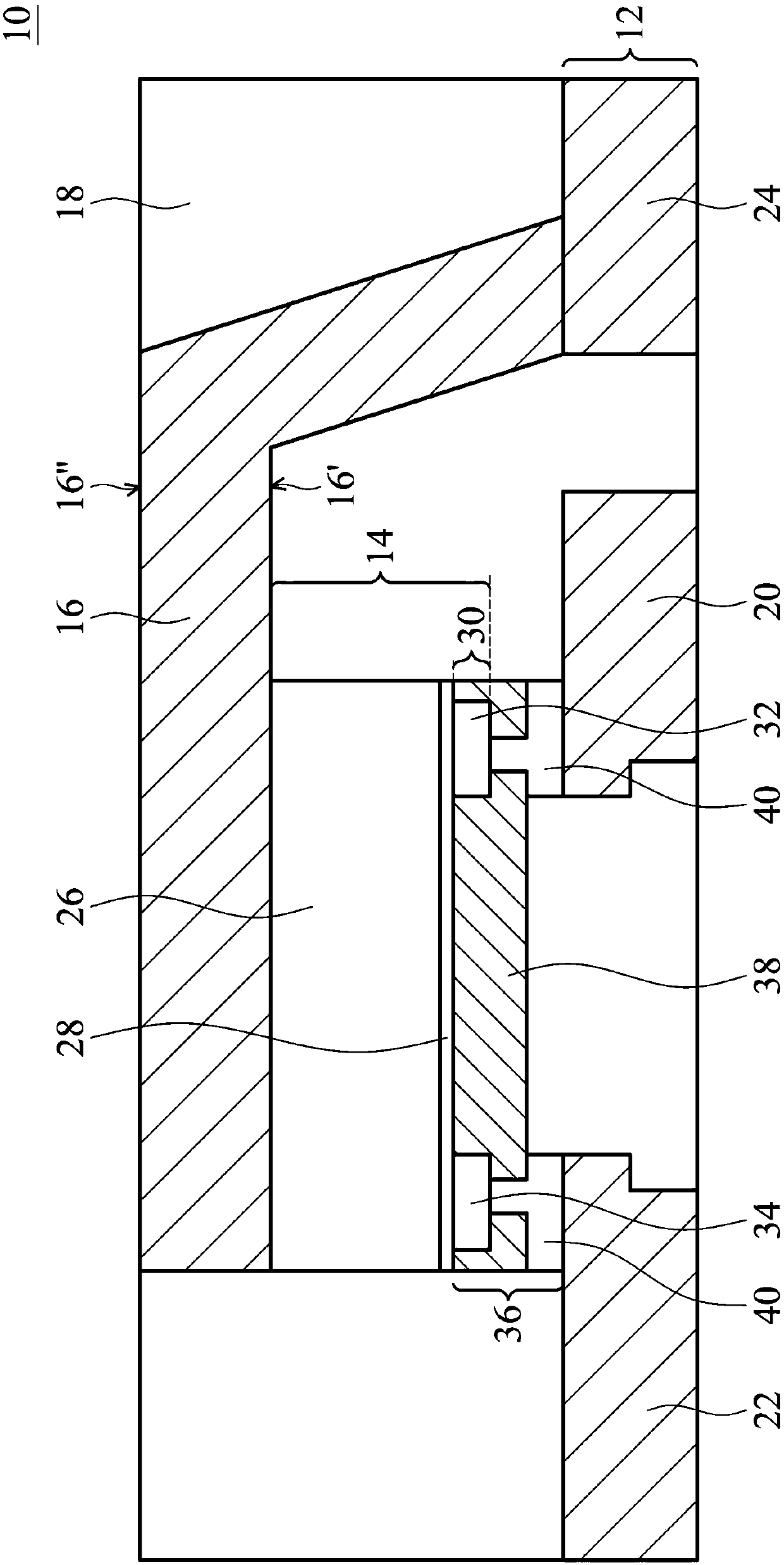

[0046] see figure 1 , according to an embodiment of the present disclosure, a package structure 10 is provided. figure 1 is a schematic cross-sectional view of the package structure 10 .

[0047] The packaging structure 10 includes a leadframe 12 , a device 14 , a conductive unit 16 , and a packaging material 18 . The lead frame 12 includes a plurality of connection parts, such as a first connection part 20 , a second connection part 22 , and a third connection part 24 . The device 14 includes a substrate 26 , an active layer 28 , and a plurality of electrodes 30 , such as a first electrode 32 and a second electrode 34 . The active layer 28 is disposed on the substrate 26 . The electrode 30 is disposed on the active layer 28 . It should be noted that the electrode 30 of the device 14 is connected to the connecting portion of the lead frame 12, for example, the first electrode 32 of the device 14 is connected to the first connecting portion 20 of the lead frame 12, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com