Washable polyaniline/terylene composite conductive fabric and manufacture method thereof

A technology of composite conduction and manufacturing method, which is applied in the direction of textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of fabrics not resistant to washing, weak polyaniline binding force, poor fastness, etc., and achieve excellent electrical conductivity and durability Washing performance, improving washing fastness, and increasing water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

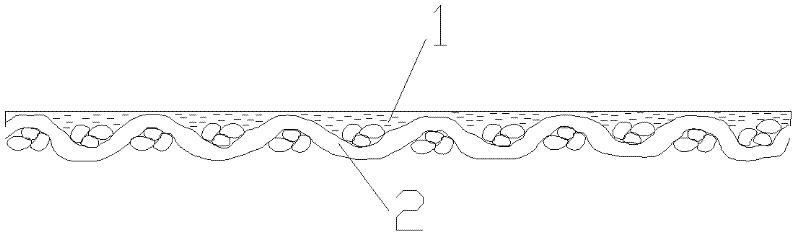

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of manufacturing method of washable polyaniline / polyester composite conductive fabric, comprises the following steps:

[0035] (1) Alkali weight reduction pretreatment: first, the polyester base fabric is treated with 20g / L caustic soda solution, treated at 90°C for 90min, washed with water and dried.

[0036] (2) Hydrochloric acid solution of padding oxidant: then the polyester base cloth treated in step (1) is padded in the hydrochloric acid solution of ammonium persulfate at a temperature of 0°C, wherein the concentration of ammonium persulfate in the solution is 0.2mol / L, the concentration of hydrochloric acid is 0.5mol / L. Control the liquid-carrying rate to about 40%. drying;

[0037] (3) Padding reaction solution: dissolve N-methyl-N-hydroxyethylaniline monomer and p-toluenesulfonic acid in water, and add water-based isocyanate to form a reaction solution, stir evenly, N-methyl-N-hydroxyethylaniline The concentration of ethylaniline monome...

Embodiment 2

[0039] Embodiment 2: a kind of manufacturing method of washable polyaniline / polyester composite conductive fabric, comprises the following steps:

[0040] (1) Alkali decrement pretreatment: first, treat the polyester base fabric with 30g / L caustic soda solution, treat it at 85°C for 80min, wash and dry it with water;

[0041] (2) the hydrochloric acid solution of padding oxidant: then the dacron base cloth that step (1) will be processed is padded in the hydrochloric acid solution of the iron trichloride that temperature is 1 ℃, and the concentration of ferric chloride is 0.4mol / L, The concentration of hydrochloric acid is 0.8mol / L, and the liquid carrying rate is controlled at about 50%. drying;

[0042] (3) padding reaction solution: N, N-dihydroxyethylaniline and camphorsulfonic acid are dissolved in ethanol solution, and add aqueous isocyanate to form reaction solution, stir, N, N-dihydroxyethylaniline concentration is 0.2mol / L, the concentration of camphorsulfonic acid ...

Embodiment 3

[0044] Embodiment 3: a kind of manufacturing method of washable polyaniline / polyester composite conductive fabric, comprises the following steps:

[0045] (1) Alkali weight reduction pretreatment: first, treat the polyester base fabric with 40g / L caustic soda solution, treat it at 90°C for 70min, and then wash and dry it with water.

[0046] (2) Padding the hydrochloric acid solution of the oxidizing agent: then pad the treated polyester base cloth in a perchloric acid solution with a temperature of 2° C., wherein the concentration of the perchloric acid solution is 0.5 mol / L, and the liquid retention rate is controlled to be about 60%. drying;

[0047] (3) padding reaction solution: dissolve o-hydroxyaniline and dodecylbenzenesulfonic acid in isopropanol solution, and add water-based isocyanate to form a reaction solution, stir well, o-hydroxyaniline concentration is 0.15mol / L, ten The concentration of dialkylbenzenesulfonic acid is 0.07mol / L, and the addition amount (mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com