Single-component photo-curable and thermal-curable adhesive and preparation method thereof

A double-curing, one-component technology, applied in the direction of modified epoxy resin adhesives, etc., can solve the problem that the shadow part cannot be completely cured, and achieve the effect of wide application range, uniform reaction system and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

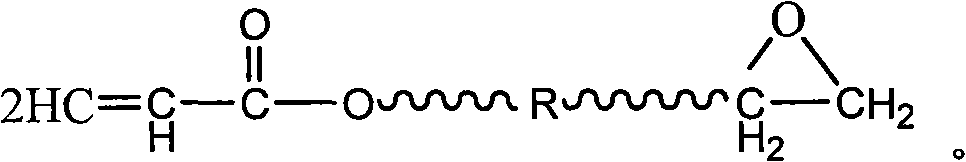

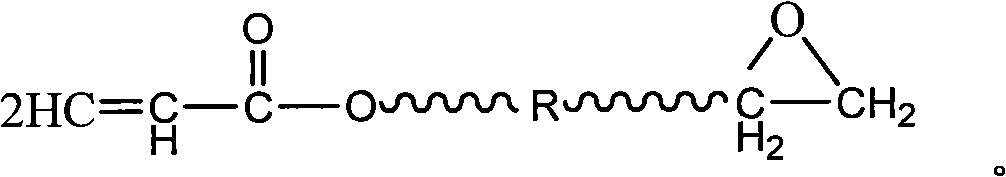

Method used

Image

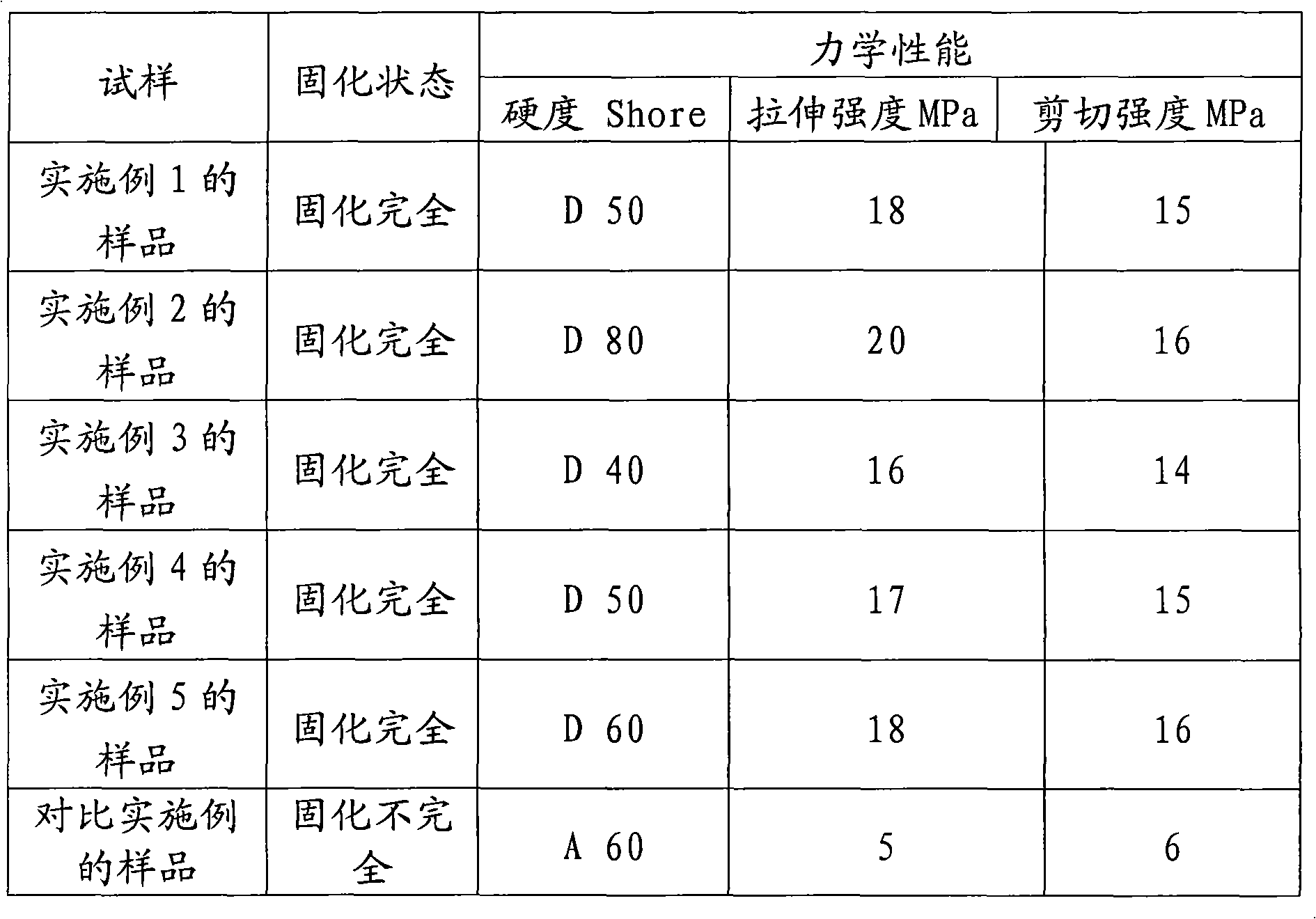

Examples

Embodiment 1

[0019] Accurately weigh each raw material according to the following weight percentages, bisphenol A epoxy resin: 5%, vinyl epoxy resin: 5%, polyurethane acrylate oligomer: 45%, IBOA: 40%, photoinitiator: 184 : 3%, latent curing agent imidazole: 2%; put the above components into the double planetary power mixing mixer in turn, vacuumize to -0.08MPa, stir at 500 rpm for 2 hours, stir evenly, naturally Let it cool down to room temperature to obtain a one-component adhesive capable of dual curing with light and heat, and then seal and pack it.

Embodiment 2

[0021] Accurately weigh each raw material according to the following weight percentages, bisphenol F epoxy resin: 10%, vinyl epoxy resin: 10%, epoxy acrylate oligomer: 28%, THFAA: 35%, photoinitiator: TPO: 3%, latent curing agent dicyandiamide: 7%, latent curing agent dicyandiamide: 7%; add the above components into the double planetary power mixing mixer in turn, and vacuum until the vacuum degree is -0.05MPa , stirred at 750 rpm for 1 hour, stirred evenly, let it air naturally to room temperature, and obtained a single-component light-heat dual-curable adhesive, which can be sealed and packaged.

Embodiment 3

[0023] Accurately weigh each raw material according to the following weight percentages, cycloaliphatic epoxy resin: 2%, vinyl epoxy resin: 2%, polyester acrylate: 50%, HDDA: 40%, photoinitiator 1173: 3%, Photoinitiator TPO: 2.5%, latent curing agent dicyandiamide: 0.5%; add the above components into the double planetary power mixer in turn, vacuumize to -0.06MPa, stir at 700 rpm for 1.5 hour, stir evenly, and let it air naturally to room temperature to obtain a single-component light-heat dual-curable adhesive, which can be sealed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com