Method for preparing disposable minimally invasive surgical scissor blades

A minimally invasive surgery, scissors blade technology, applied in surgical scissors and other directions, can solve the problems of cumbersome disinfection process, high preparation cost, cross-infection, etc., and achieve the effects of high raw material utilization, high degree of automation, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

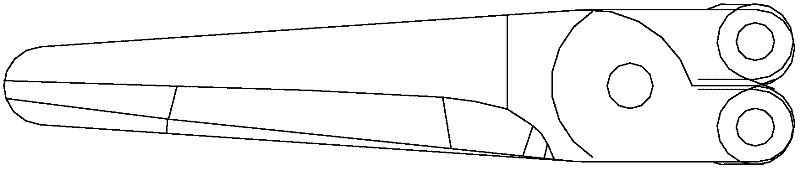

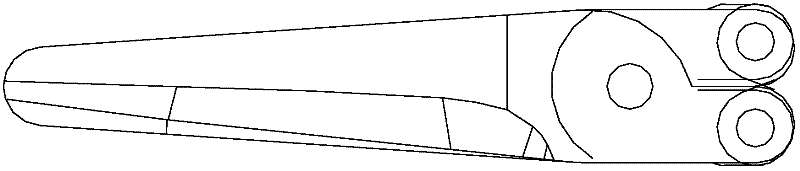

Image

Examples

Embodiment 1

[0021] a, with the 17-4PH stainless steel spherical powder with an average particle size of 8um as raw material, a disposable minimally invasive surgical scissors blade is prepared;

[0022] B, preparation of binding agent: by weight percentage, get polyethylene glycol 30%, vegetable oil 5%, polyethylene 35%, plasticizer 5%, paraffin 25%, put in blade mixer, at 150 ℃ Mix at high temperature for 1h;

[0023] c. Preparation of feed: the binder and 17-4PH stainless steel spherical powder are mixed in a mixer at 180°C for 2 hours at a volume ratio of 50%;

[0024] d. Injection molding: put the above-mentioned mixture in the injection molding machine, at an injection temperature of 185°C, an injection pressure of 90MPa, and an injection speed of 2cm 3 / s, under the condition of mold temperature 110℃, it is processed into a blank;

[0025] e. Degreasing: first put the blank in dichloromethane to dissolve the paraffin and vegetable oil components; then in an argon atmosphere, heat ...

Embodiment 2

[0029] a, the 440C stainless steel spherical powder with an average particle size of 8um is used as a raw material to prepare disposable minimally invasive surgical scissors;

[0030] B, the preparation of binding agent: by weight percentage, get polyethylene glycol 30%, vegetable oil 10%, polyethylene 30%, plasticizer 5%, paraffin 20%, put in blade type mixer, at 180 ℃ Mix at high temperature for 1.5h;

[0031] c. Ingredients: The binder and 440C stainless steel spherical powder are fed according to the volume ratio of 55%, and then mixed in a mixer at 185°C for 2 hours.

[0032] d. Injection molding: put the above-mentioned mixture in an injection molding machine, with an injection temperature of 185°C, an injection pressure of 80MPa, and an injection speed of 2cm 3 / s, processed into blanks at a mold temperature of 100°C;

[0033] e. Degreasing: first place the blank in dichloromethane to dissolve the paraffin and vegetable oil components; then in an argon atmosphere, hea...

Embodiment 3

[0037] a, the 17-4PH stainless steel spherical powder with an average particle diameter of 9um is used as a raw material to prepare disposable minimally invasive surgical scissors;

[0038] B, preparation of binding agent: by weight percentage, get polyethylene glycol 10%, vegetable oil 25%, polyethylene 35%, plasticizer 10%, paraffin 20%, put in blade mixer, at 140 ℃ Mix at high temperature for 2h;

[0039] c. Preparation of feed: the binder and 17-4PH stainless steel spherical powder are mixed in a mixer at 140°C for 3 hours at a volume ratio of 40%;

[0040] d. Injection molding: put the above-mentioned mixture in the injection molding machine, with an injection temperature of 145°C, an injection pressure of 120MPa, and an injection speed of 3cm 3 / s, under the condition of mold temperature 80℃, it is processed into blank;

[0041] e. Degreasing: first place the blank in dichloromethane to dissolve the paraffin and vegetable oil components; then in an argon atmosphere, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com