SCR (selective catalyctic reduction) low-temperature denitrification catalyst with nano core-shell structure and preparation method thereof

A nano-core-shell, low-temperature denitrification technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of ensuring the uniformity of active nanoparticles and the surface composition of activated carbon And problems such as complex structure, easy aggregation of active components, etc., to achieve the effects of easy operation, strong anti-toxicity, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

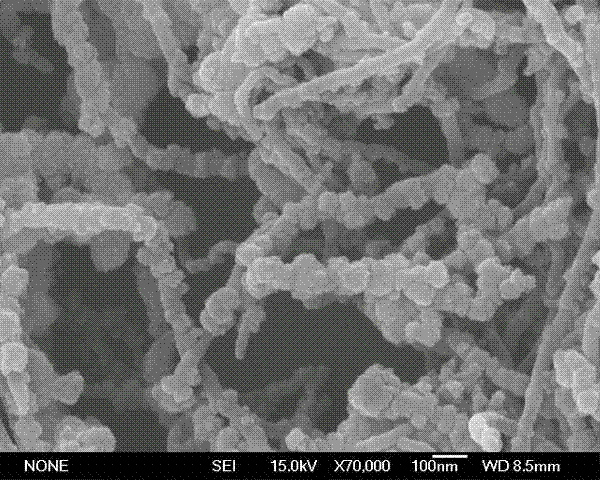

[0024] Dissolve the nitrate of manganese and cerium in pyridine, disperse the multi-walled carbon nanotubes in the pyridine solution, and transfer it to a 100ml hydrothermal kettle after ultrasonication for 0.5h. o Solvothermal reaction in C for 24h, cooled to room temperature, centrifuged and washed to neutral, at 60 o C drying. Under the protection of nitrogen atmosphere, with 2 o C / min heating rate to 550 o C calcined for 5h, cooled to room temperature with the furnace temperature to obtain the MnO with nano-core-shell structure x / CeO 2 CNTs catalyst, the mass fraction of CNTs is 28%; its active component is: MnO X and CeO 2 , where MnOX for MnO 2 , Mn 3 o 4 , Mn 2 o 3 mixture, the molar ratio of Mn / (Mn+Ce) elements is 0.2.

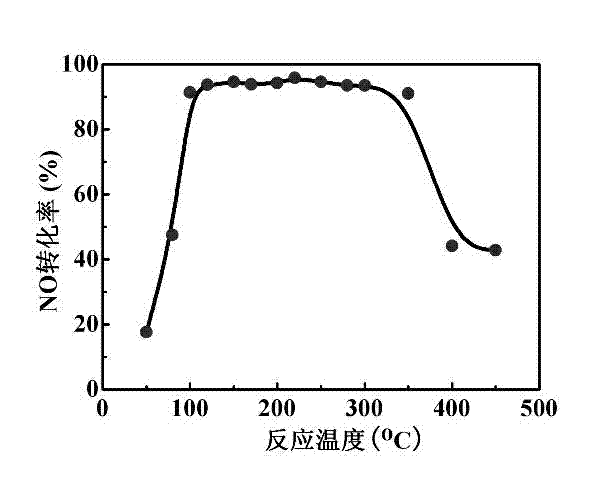

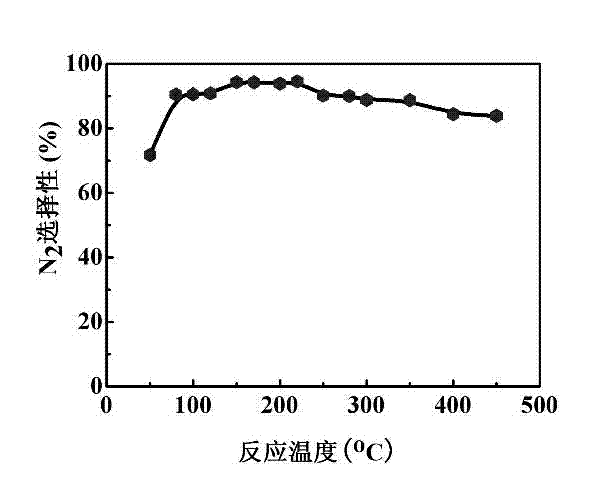

[0025] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-60 mesh particles, put them into a fixed-bed quartz tube reactor for activity and selectivity testing, the reaction temperature is 50-450°C, and the space velocity i...

Embodiment 2

[0027] Dissolve the acetate of manganese and cerium in pyridine, disperse the single-walled carbon nanotubes in the pyridine solution, and transfer it to a 200ml hydrothermal kettle after ultrasonication for 1h. o Solvothermal reaction in C for 48h, cooled to room temperature, centrifuged and washed to neutral, at 60 o C drying. Under the protection of nitrogen atmosphere, with 6 o C / min heating rate to 500 o C calcined for 6h, cooled to room temperature with the furnace temperature to obtain the MnO with nano-core-shell structure x / CeO 2 CNTs catalyst, the mass fraction of CNTs is 55%, and its active component is: MnO X and CeO 2 , where MnO X for MnO 2 , Mn 3 o 4 , Mn 2 o 3 mixture, the molar ratio of Mn / (Mn+Ce) elements is 0.4.

[0028] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-60 mesh particles, put them into a fixed-bed quartz tube reactor for activity and selectivity testing, the reaction temperature is 50-500°C, and the space veloc...

Embodiment 3

[0030] Dissolve the chloride salt of manganese and cerium in pyridine, disperse the multi-walled carbon nanotubes in the pyridine solution, and transfer it to a 100ml hydrothermal kettle after ultrasonication for 0.5h. o Solvothermal reaction in C for 48h, cooled to room temperature, centrifuged and washed to neutral, at 60 o C drying. Under the protection of nitrogen atmosphere, with 4 o C / min heating rate to 600 o C calcined for 4.5h, and cooled to room temperature with the furnace temperature to obtain the MnO with the nano-core-shell structure x / CeO 2 CNTs catalyst, the mass fraction of CNTs is 40%, and its active component is: MnO X and CeO 2 , where MnO X for MnO 2 , Mn 3 o 4 , Mn 2 o 3 mixture, the molar ratio of Mn / (Mn+Ce) elements is 0.2.

[0031] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-60 mesh particles, put them into a fixed-bed quartz tube reactor for activity and selectivity testing, the reaction temperature is 50-500°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com