Processing method for efficiently removing deoxynivalenol (DON) from wheat grains

A technology for deoxynivalenol and wheat grains, which is applied in the field of processing to efficiently remove deoxynivalenol from wheat grains, and can solve problems such as safety concerns, damage to food nutrients, and ineffective detoxification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

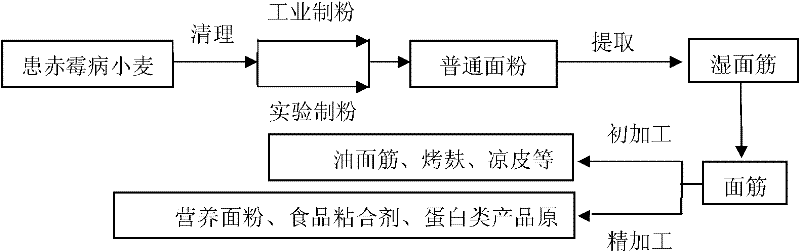

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, remove the deoxynivalenol (DON) toxin in wheat grain

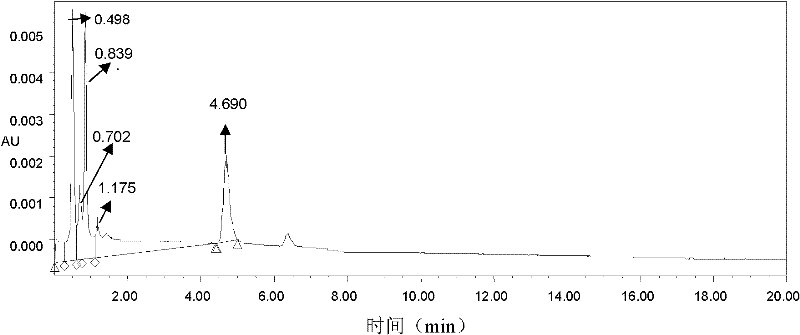

[0040] The method for extracting and detecting DON toxin content in wheat grain is as follows:

[0041] A) Extraction of DON

[0042] Grind the dried wheat grain sample (collected from the southern Jianghuai wheat producing area of my country) polluted by DON toxin with a pulverizer, weigh 5 g accurately, place it in a 100 mL Erlenmeyer flask, add 35 mL of acetonitrile / water solution (84:16 , V / V), vibrated with a disperser for 3 minutes, mixed evenly, poured into a volumetric flask, added acetonitrile / water solution (84:16, V / V) to make the volume to 50mL, folded and filtered all the sample liquid with qualitative filter paper, and obtained supernatant.

[0043] Take 4mL of the supernatant, pass through the Bond Elut Mycotoxin purification column, accurately draw 3mL of the purification solution, transfer it to a graduated test tube, blow in nitrogen slowly with a nitrogen purging instrument at 50°C...

Embodiment 2

[0059] Embodiment 2, remove the deoxynivalenol (DON) toxin in wheat grain

[0060] Take by weighing the same wheat grain 1000g contaminated by DON toxin as in Example 1, and use the same method in Example 1 to detect that the DON toxin content in the wheat grain is 9.21 μg / g; according to NY / T 1094.1-2006 And NY / T 1094.5-2006, using Brabender experimental grinding Quadrumat (Quadruplex), to obtain 466.28g flour. The same method as in Example 1 was used to detect that the DON toxin content in the flour was 7.33 μg / g. Take 100g of flour, and add 52ml of 1g / L sodium chloride aqueous solution to it to make dough, wash the dough with a suitable flow rate, and knead the dough continuously at the same time. And continue to rinse and knead the formed gluten balls with tap water until the starch in the gluten is washed. The criterion for the washing of the starch in the gluten is: after adding potassium iodide / iodine solution to the water squeezed from the gluten, The color of the wa...

Embodiment 3

[0062] Embodiment 3, remove the deoxynivalenol (DON) toxin in wheat grain

[0063] Take by weighing the same wheat grain 1000g contaminated by DON toxin as in Example 1, and use the same method in Example 1 to detect that the DON toxin content in the wheat grain is 9.21 μg / g; according to NY / T 1094.1-2006 And NY / T 1094.5-2006, using Brabender experimental grinding Quadrumat (Quadruplex), to obtain 477.76g flour. The same method as in Example 1 was used to detect that the DON toxin content in the flour was 7.33 μg / g. Take 100g of flour, add 46ml of drinking water to it, and after making dough, wash the dough with an appropriate flow rate while kneading the dough continuously. And continue to rinse and knead the formed gluten balls with tap water until the starch in the gluten is washed away. The judgment standard for washing the starch in the gluten is: the water squeezed out from the gluten is colorless, drained and pressed to dry. To obtain wet gluten, dry the wet gluten at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com