Cross-scale micro-nano in-situ three-point bending mechanical performance testing platform

A technology of three-point bending and testing platform, which is applied in the direction of applying stable bending force to test the strength of materials, nanotechnology, etc., can solve the problems of low test accuracy, poor compatibility, and high cost, and achieve a wide range of applications, compact structure, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

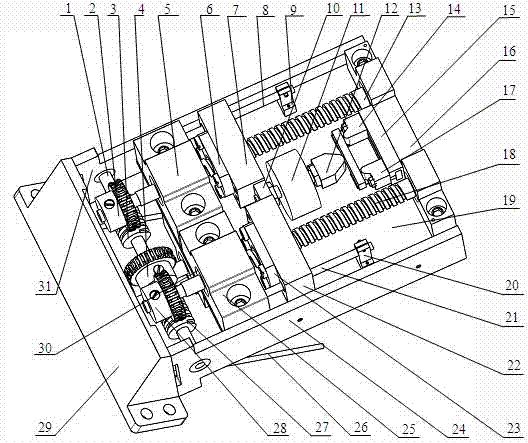

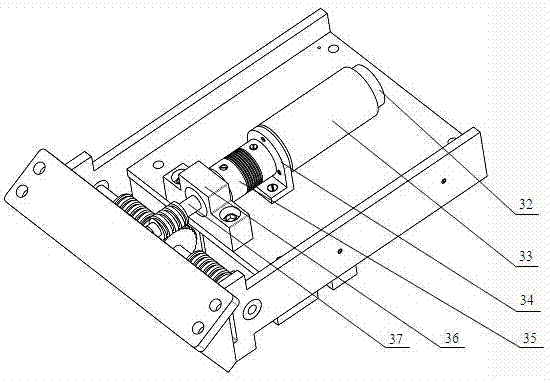

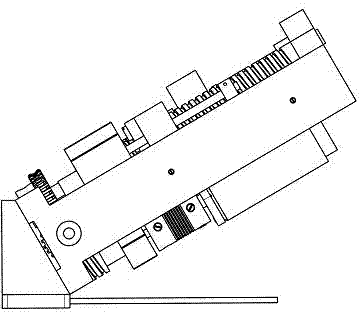

[0025] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0026] see Figure 1 to Figure 4, the cross-scale micro-nano level in-situ three-point bending mechanical performance test platform of the present invention includes a precision drive unit, a transmission and execution unit, a signal control and detection unit, a connection and a support unit, and the precision drive unit, transmission and execution unit The power output is provided by a brushless DC servo motor 33. The brushless DC servo motor 33 is connected to the primary worm 37 through a bellows elastic coupling 35, and is fastened to the secondary worm shaft 1 by the primary worm 37. The first-stage worm gear and worm transmission pair composed of the first-stage worm gear 4 is connected to the second-stage worm shaft 1, and the power is transmitted to the second-stage worm shaft 1, and then passed through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com