Titanium dioxide-hydroxyapatite gradient coating of medical titanium or titanium alloy surface and preparation method

A technology of hydroxyapatite and titanium dioxide, which is applied in metal material coating technology, coating, medical science, etc., can solve the problems of easy peeling off of the coating, low bonding strength between the coating and the substrate, etc., so as to improve the bonding performance and improve the The effect of peeling coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

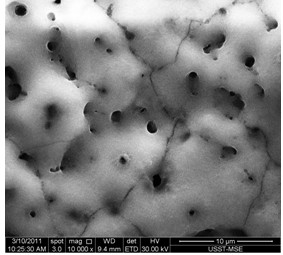

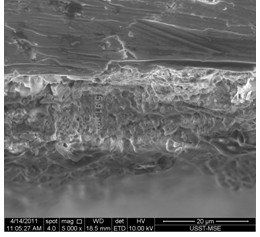

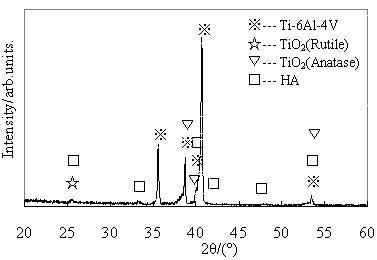

Image

Examples

Embodiment 1

[0043] A preparation method of a titanium dioxide-hydroxyapatite gradient coating on the surface of a titanium alloy, specifically comprising the steps of:

[0044] (1) Surface pretreatment of the titanium alloy, grinding and polishing the surface with No. 200, No. 400, No. 600, and No. 800 sandpaper in sequence, and then cleaning and drying;

[0045] (2) Prepare 0.1mol / L calcium acetate aqueous solution and 0.02mol / L sodium dihydrogen phosphate aqueous solution. According to the volume ratio, calcium acetate aqueous solution: sodium dihydrogen phosphate aqueous solution is mixed at 1:1 to make an electrolyte;

[0046] (3) With the titanium alloy pretreated in step (1) as the anode and the metal stainless steel as the cathode, place the titanium alloy in the electrolyte obtained in step (2), and use a DC pulse power supply with a constant voltage of 460V for 5 minutes micro-arc oxidation treatment;

[0047] (4) Using calcium nitrate and triethyl phosphate as precursors, hydro...

Embodiment 2

[0055] A preparation method of a titanium dioxide-hydroxyapatite gradient coating on the surface of a titanium alloy, specifically comprising the steps of:

[0056] (1) Surface pretreatment of the titanium alloy, grinding and polishing the surface with No. 200, No. 400, No. 600, and No. 800 sandpaper in sequence, and then cleaning and drying;

[0057] (2) Prepare 0.5mol / L calcium acetate aqueous solution and 0.1mol / L sodium dihydrogen phosphate aqueous solution. According to the volume ratio, calcium acetate aqueous solution: sodium dihydrogen phosphate aqueous solution is mixed at 1:1 to make electrolyte;

[0058] (3) With the titanium alloy pretreated in step (1) as the anode and the metal stainless steel as the cathode, place the titanium alloy in the electrolyte obtained in step (2), and use a DC pulse power supply with a constant voltage of 400V for 20 minutes micro-arc oxidation treatment;

[0059] (4) Using calcium nitrate and triethyl phosphate as precursors, the hydr...

Embodiment 3

[0064] A preparation method of a titanium dioxide-hydroxyapatite gradient coating on the surface of a titanium alloy, specifically comprising the steps of:

[0065] (1) Surface pretreatment of the titanium alloy, grinding and polishing the surface with No. 200, No. 400, No. 600, and No. 800 sandpaper in sequence, and then cleaning and drying;

[0066] (2) Prepare 0.5mol / L calcium acetate aqueous solution and 0.1mol / L sodium dihydrogen phosphate aqueous solution. According to the volume ratio, calcium acetate aqueous solution: sodium dihydrogen phosphate aqueous solution is mixed at 1:1 to make electrolyte;

[0067] (3) With the titanium alloy pretreated in step (1) as the anode and the metal stainless steel as the cathode, place the titanium alloy in the electrolyte obtained in step (2), and use a DC pulse power supply with a constant voltage of 500V for 5 minutes micro-arc oxidation treatment;

[0068] (4) Using calcium nitrate and triethyl phosphate as precursors, hydroxyap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com