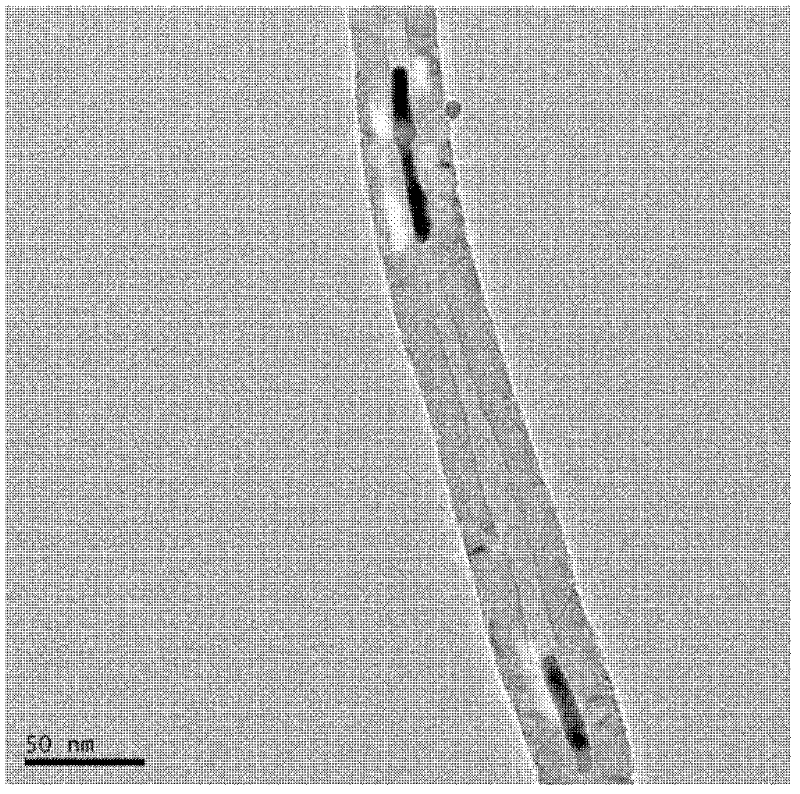

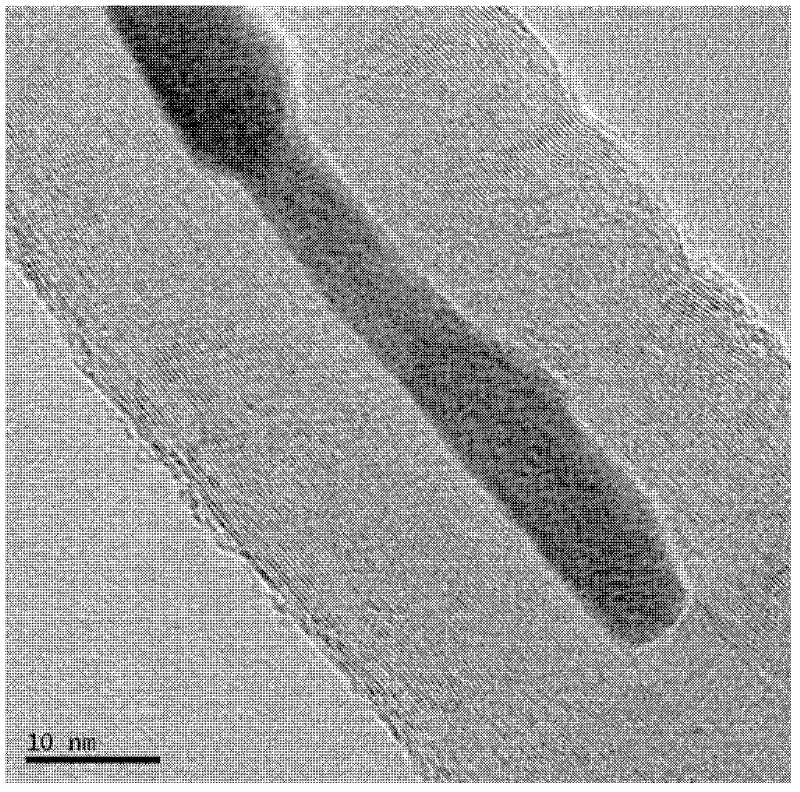

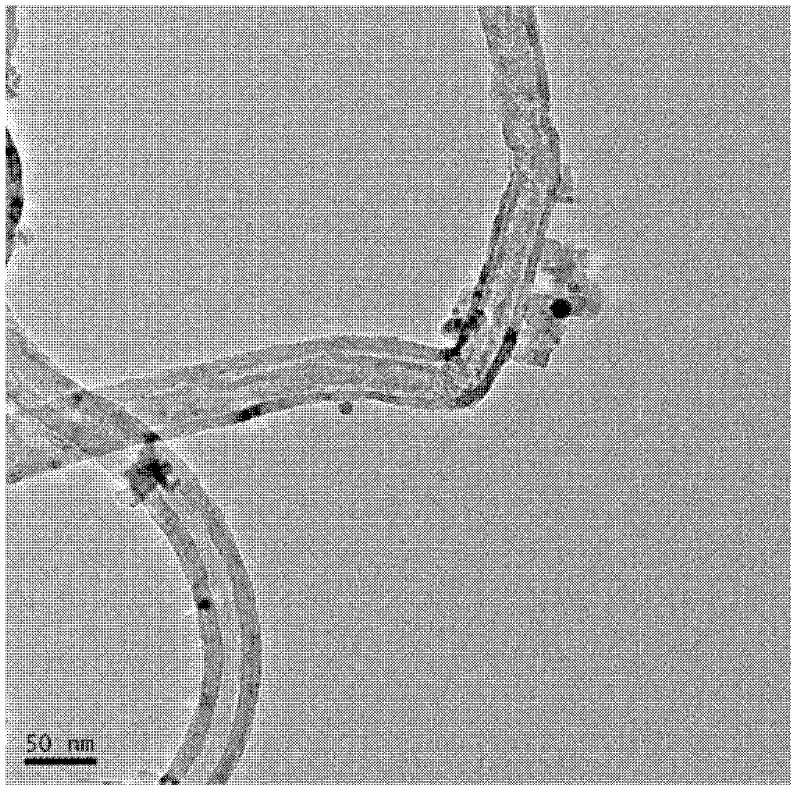

Preparation method of carbon nano tube

A carbon nanotube and substrate technology, which is applied in the field of carbon nanotube preparation and achieves the effects of fast deposition rate, good deposition quality and large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing carbon nanotubes is prepared by a direct current plasma jet chemical vapor deposition system, and the steps are as follows:

[0027] 1) Dissolve 14.5g of nickel nitrate and 13g of magnesium nitrate crystals in 100mL of absolute ethanol to prepare a mixed solution as a catalyst precursor, and prepare Ni(NO 3 ) 2 And Mg(NO 3 ) 2 The concentration is 0.5mol / L, Ni(NO 3 ) 2 With Mg(NO 3 ) 2 A mixed solution with a molar ratio of 1:1;

[0028] 2) Drop the above-mentioned mixed solution evenly on the molybdenum platform and let it dry naturally;

[0029] 3) Wrap the tin wire in a ring shape eight times to pad under the molybdenum table, and place them on the deposition table in the chamber of the DC plasma jet chemical vapor deposition equipment;

[0030] 4) Close the vacuum chamber and turn on the vacuum pump and water pump to vacuum. When the pump pressure is less than 3kpa, turn on the Roots pump. When the pump pressure is less than 0.1pa, pass argon and hydro...

Embodiment 2

[0035] A method for preparing carbon nanotubes is prepared by a direct current plasma jet chemical vapor deposition system, and the steps are as follows:

[0036] 1) Dissolve 8.93g of nickel nitrate and 2.56g of magnesium nitrate crystals in 100mL of absolute ethanol to prepare a mixed solution as the catalyst precursor, and prepare Ni(NO 3 ) 2 And Mg(NO 3 ) 2 The concentration is 0.1mol / L, Ni(NO 3 ) 2 With Mg(NO 3 ) 2 A mixed solution with a molar ratio of 3:1;

[0037] 2) Drop the above-mentioned mixed solution evenly on the molybdenum platform and let it dry naturally;

[0038] 3) Wrap the tin wire in a ring shape eight times to pad under the molybdenum table, and place them on the deposition table in the chamber of the DC plasma jet chemical vapor deposition equipment;

[0039] 4) Close the vacuum chamber and turn on the vacuum pump and water pump for vacuuming. When the pump pressure is less than 3kpa, turn on the Roots pump. When the pump pressure is less than 0.1pa, pass argon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com