Control method of form of nonmetallic inclusion in steel

A technology of non-metallic inclusions and shapes, applied in the field of metallurgy, can solve the problems of high cost, broken wires, affecting the cleanliness of molten steel, etc., and achieve the effect of improving service life and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

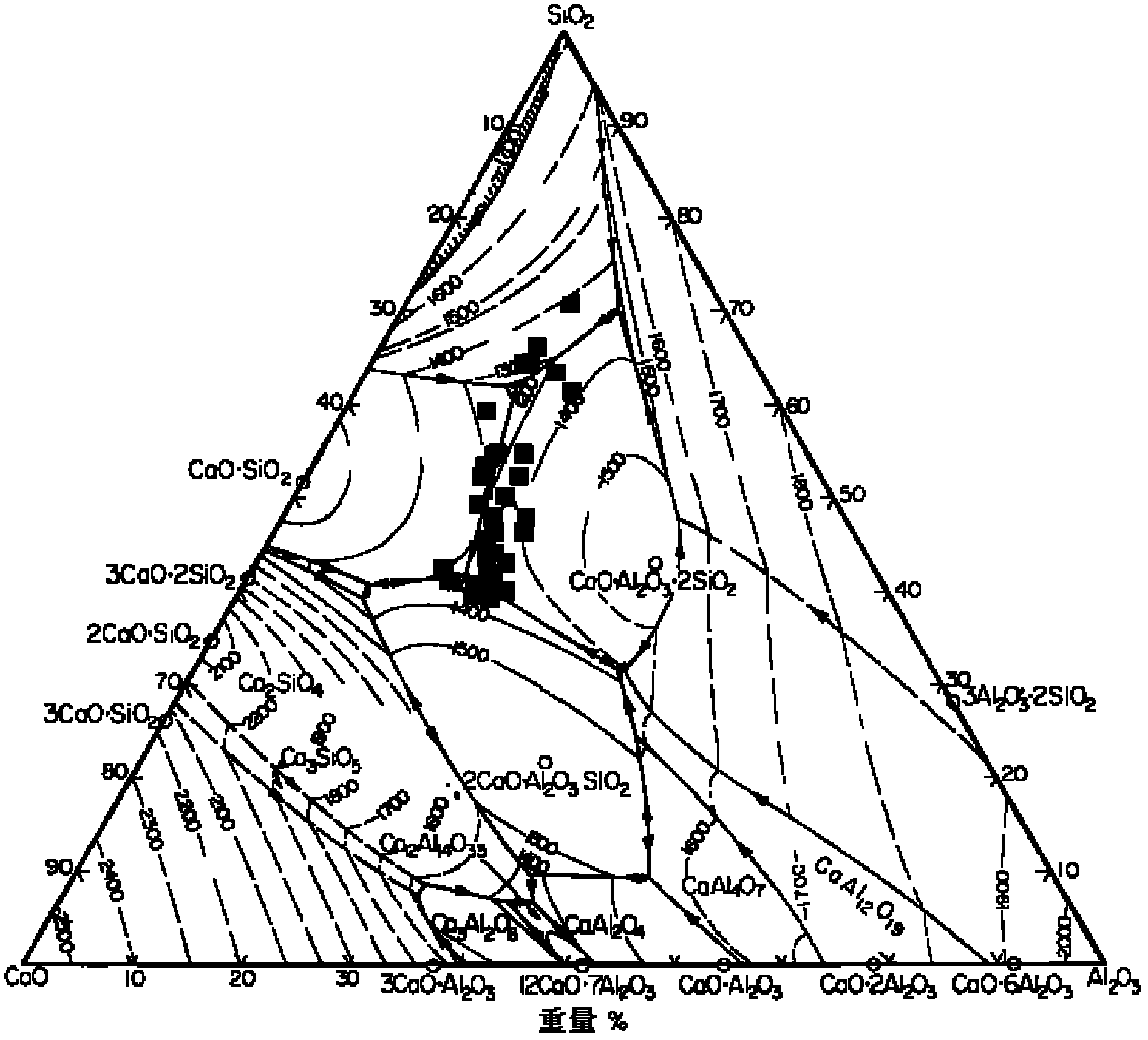

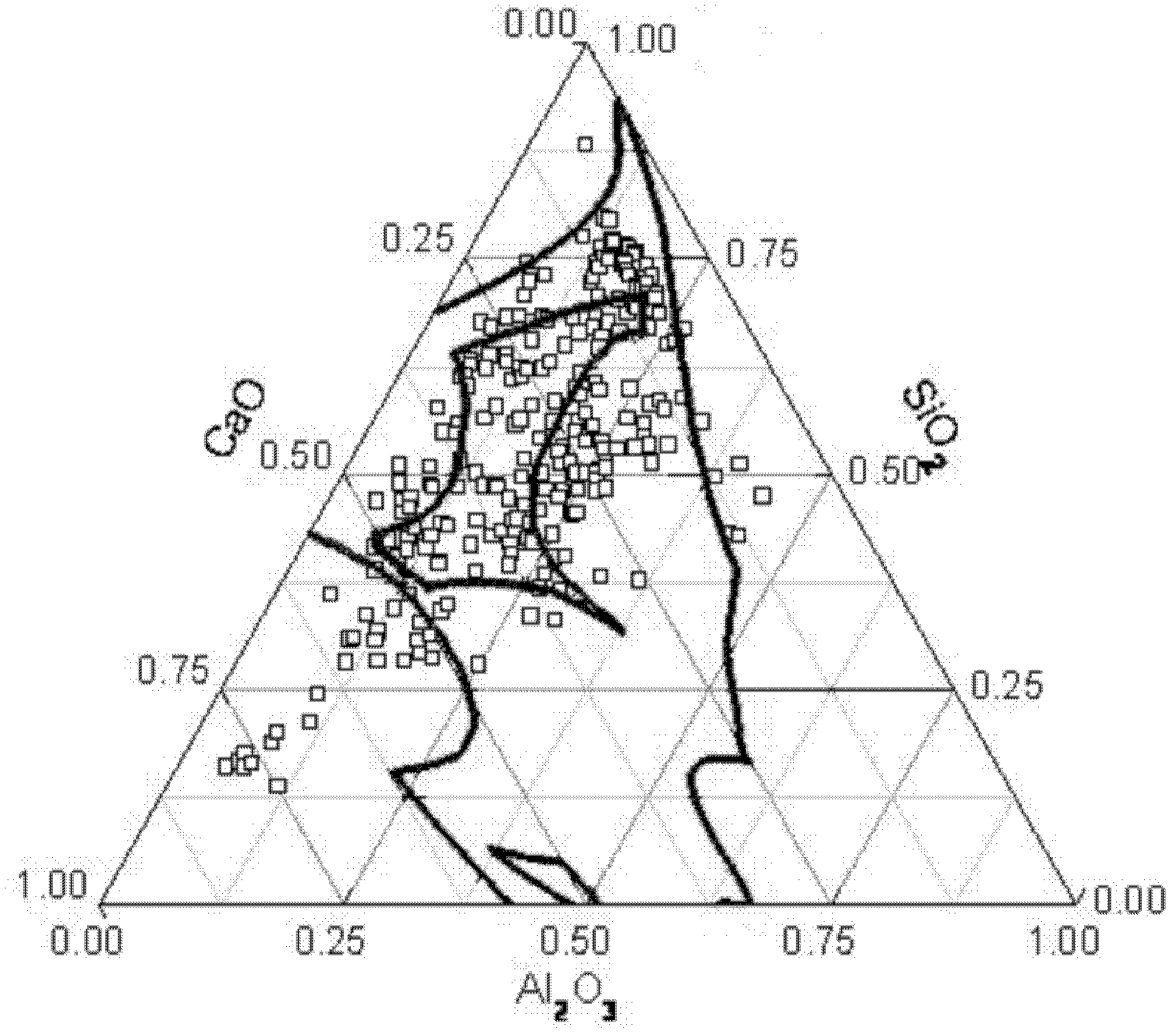

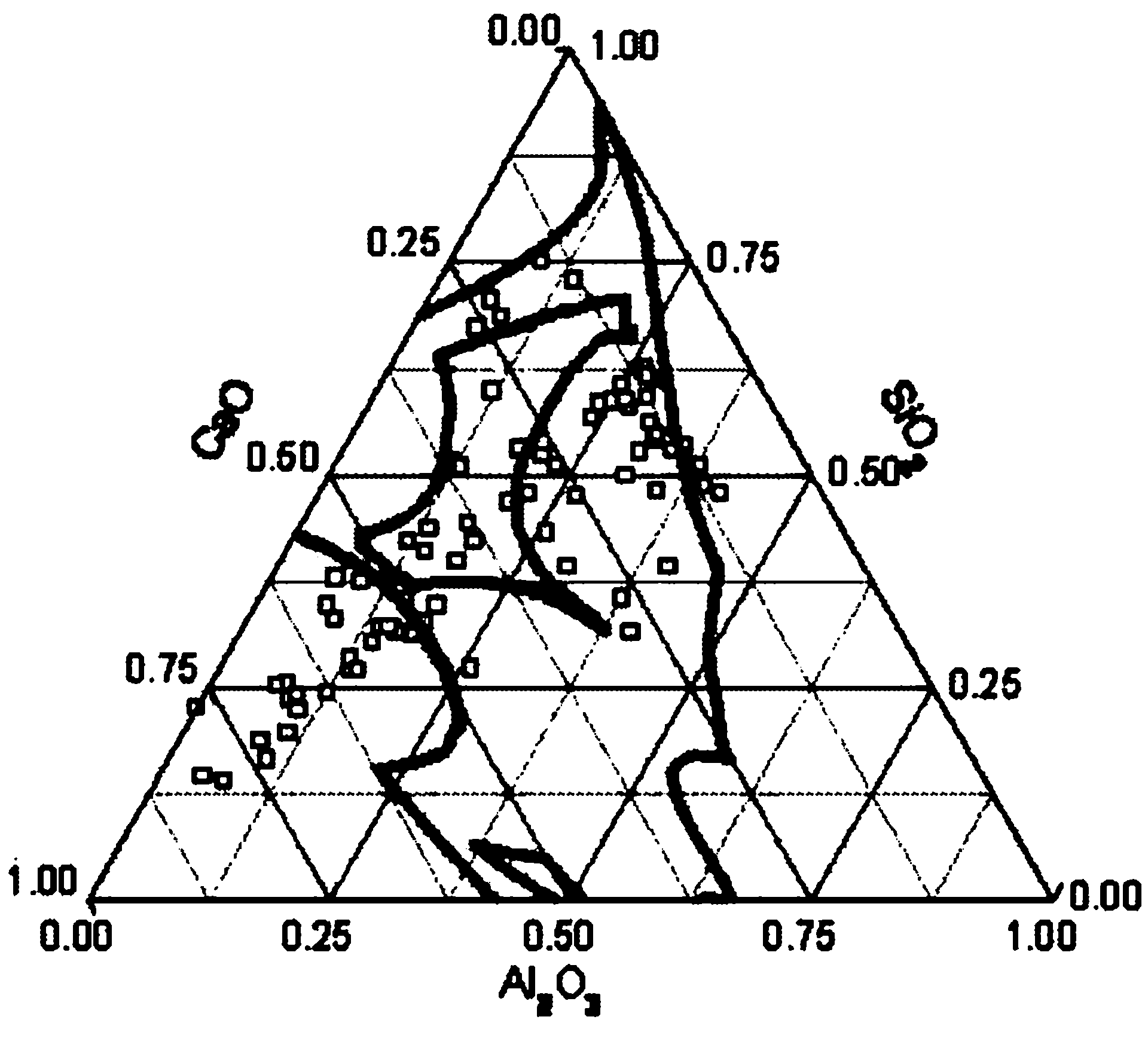

Image

Examples

Embodiment 1

[0035] Embodiment 1 adopts process technology of the present invention to smelt cord steel (72LX) molten steel

[0036] (1) Converter smelting

[0037] During converter smelting, 140-145 tons of molten iron is added into the converter for top-bottom double-blowing converter blowing, and the end temperature of blowing is 1670-1690°C.

[0038] (2) Converter tapping

[0039] During the tapping process of the converter, the alloying of C, Si and Mn elements is carried out, and then the low-alkalinity refining slag (particle diameter is 0-8mm) is added into the ladle along with the steel flow, and the amount of refining slag added is 5-6kg / t Molten steel, the ladle is blown with argon at the bottom during the tapping process, the flow rate of the molten steel blowing argon is 100-150NL / min, and the argon blowing time is 10-17min; after tapping, the molten steel is softly stirred for ≥10min. The weight composition ratio of the main components of the low alkalinity refining slag us...

Embodiment 2

[0049] Embodiment 2 adopts process technology of the present invention to smelt hard wire steel (60 steel) molten steel

[0050] (1) Converter smelting

[0051] During converter smelting, 135-140 tons of molten iron is added into the converter for top-bottom re-blowing converter blowing, and the end temperature of blowing is 1670-1690 °C.

[0052] (2) Converter tapping

[0053] During the tapping process of the converter, the alloying of C, Si and Mn elements is carried out, and then the low-alkalinity refining slag (particle diameter is 0-8mm) is added into the ladle along with the steel flow, and the amount of refining slag added is 6-7kg / t Molten steel, during the tapping process, the ladle is blown with argon at the bottom, the flow rate of the molten steel blowing argon is 100-150NL / min, and the argon blowing time is 4-10min; after tapping, the molten steel is softly stirred for ≥10min. The weight composition ratio of the main components of the low alkalinity refining s...

Embodiment 3

[0063] Embodiment 3 adopts process technology of the present invention to smelt steel strand steel (82B) molten steel

[0064] (1) Converter smelting

[0065] During converter smelting, 140-145 tons of molten iron is added into the converter for top-bottom double-blowing converter blowing, and the final temperature of blowing is 1670-1690°C.

[0066] (2) Converter tapping

[0067]During the tapping process of the converter, the alloying of C, Si and Mn elements is carried out, and then the low-alkalinity refining slag (particle diameter is 0-8mm) is added into the ladle along with the steel flow, and the amount of refining slag added is 8-9kg / t Molten steel, the ladle is blown with argon at the bottom during the tapping process, the flow rate of the molten steel blowing argon is 100-150NL / min, and the argon blowing time is 6-13min; after tapping, the molten steel is softly stirred for ≥15min. The weight composition ratio of the main components of the low alkalinity refining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com