Comprehensive utilization method of aluminum-containing minerals

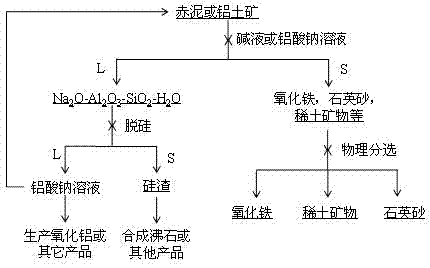

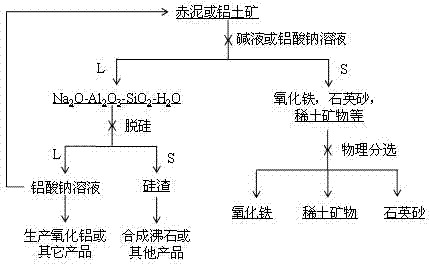

A technology of minerals and mineral raw materials, applied in the field of comprehensive utilization of aluminum-containing minerals, can solve problems such as unfavorable comprehensive utilization of iron and rare earth elements, red mud alkali pollution, loss of sodium and aluminum, and achieve the effect of avoiding pollution and corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 100 g of dry red mud from an alumina plant in Shandong, and mix it with Na 2 o k Concentration 500 g / L lye 2 L mixed and heated to 20 o C, stirred for 8 h. After solid-liquid separation, 1.9 L of eluate was obtained, in which SiO 2 and Al 2 o 3 The content of zeolite is 6.54 g / L, 7.72 g / L, and the dissolution rate is 64% and 82% respectively; The zeolite product was obtained under hydrothermal conditions; 72.29g of the solid phase was obtained after dissolution, in which Fe 2 o 3 、TiO 2 The content reaches 46.42% and 2.35% respectively, SiO 2 The content is 9.51%, identified by XRD as SiO 2 Predominantly exists in the less reactive form of quartz. Quartz and iron oxide in the solid phase can be separated well. After separation by chute and shaking table, the total iron content in the iron concentrate is 55.05%.

[0035] Table 1 Composition in samples before and after dissolution

[0036] sample SiO 2 Fe 2 o 3 al 2 o 3 Na 2 o TiO...

Embodiment 2

[0038] The A / S of some bauxite in Henan was only 4.31, and 1000 g of the sample below 100 mesh was taken, and Na 2 o k Concentration 450 g / L lye 25 L mixed and heated to 220 o C, stirred for 5 h. After solid-liquid separation, 24.86 L of solution was obtained, in which SiO 2 and Al 2 o 3 The contents of 3.92 g / L and 21.19 g / L respectively; the dissolution liquid enters the alumina production process to prepare alumina, and the desilication product is adjusted and used to prepare zeolite; 375.12 g of dissolution slag is obtained by dissolution, the main element of which is CaO, and Residual SiO 2 and Al 2 o 3 , while rare earth elements such as Ce are also enriched.

[0039] Table 2 Composition in samples before and after dissolution

[0040] sample SiO 2 Fe 2 o 3 al 2 o 3 Na 2 o Ce CaO Bauxite, % 13.53 4.36 57.89 0.78 172.93×10 -4 15.44 Eluate, g / L 3.92 0.002 21.19 450.21 --- 0.06 Solid Phase,% 9.88 11.74 13...

Embodiment 3

[0042] Take 1000 g of bauxite from somewhere in Guigang, Guangxi, and mix it with Na 2 o k Concentration 200 g / L, α k =1.5 sodium aluminate lye 10 L mixed and heated to 220 o C, stirred for 0.5 h. After solid-liquid separation, 9.7 L of solution was obtained, in which SiO 2 and Al 2 o 3 The contents of the solution are 6.45 g / L and 289.11 g / L respectively; after desiliconization of the dissolution solution, part of the solution returns to the dissolution process, and part of it enters the alumina production process to prepare alumina, and the desilication slag is used to prepare zeolite after adjustment; the dissolution slag is obtained by dissolution 552.85g, the main element of which is Fe 2 o 3 , can be used directly as iron concentrate.

[0043] Table 3 Composition in samples before and after dissolution

[0044] sample SiO 2 Fe 2 o 3 Al 2 o 3 Na 2 o TiO 2 CaO Bauxite, wt% 8.54 43.67 45.89 1.53 2.30 3.45 Eluate, g / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com