Method for preparing carbon-loaded platinum-based electro-catalyst by microwave organosol method

An organosol, fuel cell technology, applied in battery electrodes, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of small particle size of platinum black catalyst, unfavorable mass production, and complicated operation, and achieve small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

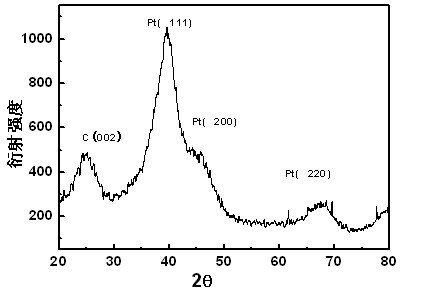

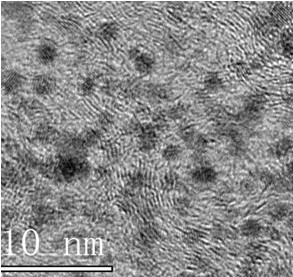

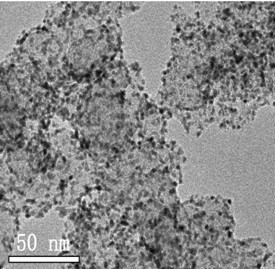

Image

Examples

Embodiment 1

[0045] (1) Stir XC-72 carbon powder (Carbot, USA) and acetone solution at room temperature, filter with suction, wash the filter cake with deionized water and dry it in vacuum, add the dried filter cake to the mass fraction of 10% HNO 3 solution and H 2 o 2 In the mixed solution of the solution, reflux at 70°C for 8 hours to obtain a reflux reaction solution, filter the reflux reaction solution and wash the filter cake with deionized water until the filtrate is neutral, dry the filtered filter cake under vacuum, cool Post-grinding to obtain pretreated carbon powder; HNO 3 solution and H 2 o 2 The volume ratio of the solution is 2:1;

[0046] (2) Add 0.151g of sodium citrate to ethylene glycol, stir until the sodium citrate is dissolved to obtain a solution; the concentration of sodium citrate in the solution is 7.54g / l;

[0047] (3) Add H dropwise to the solution in step (2) 2 PtCl 6 H at a concentration of 0.02g / ml 2 PtCl 6 6.64ml of ethylene glycol solution to obta...

Embodiment 2

[0055] (1) Stir XC-72 carbon powder and acetone solution at room temperature, filter with suction and wash the filter cake with deionized water, then vacuum-dry it, and add the dried filter cake to 5% HNO 3 and 15%H 2 o 2 In the mixed solution, reflux at 90°C to obtain a reflux reaction solution, filter the reflux reaction solution and wash the filter cake with deionized water until the filtrate is neutral, dry the obtained filter cake under vacuum, cool and grind to obtain pretreatment toner; HNO 3 and H 2 o 2 The volume ratio is 5:1;

[0056] (2) Add 0.316g of sodium citrate to ethylene glycol, stir until the sodium citrate dissolves, and obtain a solution; the concentration of sodium citrate in the solution is 15.78g / l;

[0057] (3) Add H dropwise to the solution in step (2) 2 PtCl 6 H at a concentration of 0.02g / ml 2 PtCl 6 11.3ml of ethylene glycol solution to obtain a mixed solution, and H in the resulting mixed solution 2 PtCl 6 The concentration is 7.98g / ml...

Embodiment 3

[0065] (1) Stir XC-72 carbon powder and acetone solution at room temperature, filter with suction and wash the filter cake with deionized water, then vacuum-dry it, and add the dried filter cake to 15% HNO 3 solution and 10% H 2 o 2 In the mixed solution of the solution, reflux reaction at 80°C for 10 hours to obtain a reflux reaction solution, filter the reflux reaction solution and wash the filter cake with deionized water until the filtrate is neutral, dry the obtained filter cake under vacuum, and after cooling Grinding to obtain pretreated carbon powder; HNO 3 solution and H 2 o 2 The volume ratio of the solution is 4:1;

[0066] (2) Add 0.602g of sodium citrate to ethylene glycol, stir until it dissolves to obtain a solution; the concentration of sodium citrate in the solution is 12.04g / l;

[0067] (3) Add dropwise H at a concentration of 0.04g / ml to the solution in step (2) 2 PtCl 6 8.85ml of ethylene glycol solution to obtain a mixed solution, the H in the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com