Ionization chamber of photoionization gas detecting instrument based on printed circuit board process

A gas detector and printed circuit board technology, applied in circuits, electrical components, instruments, etc., can solve the problems of large volume, short optical path length, insufficient gas ionization, etc., and achieve the effect of small volume and ensuring optical path length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

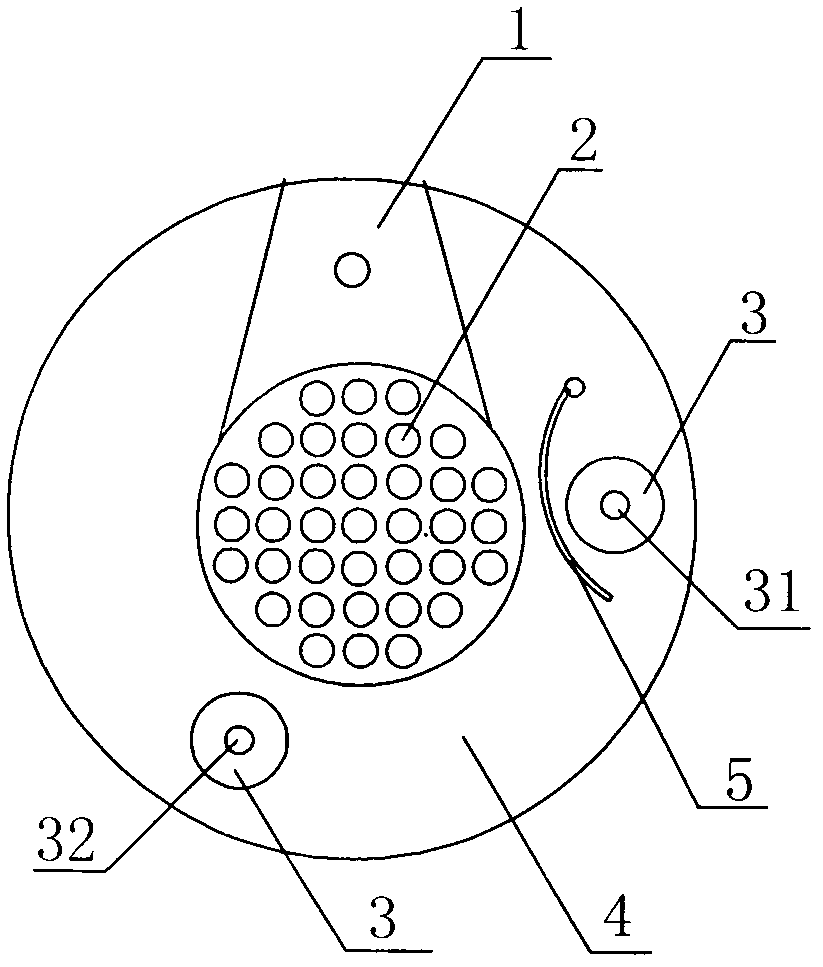

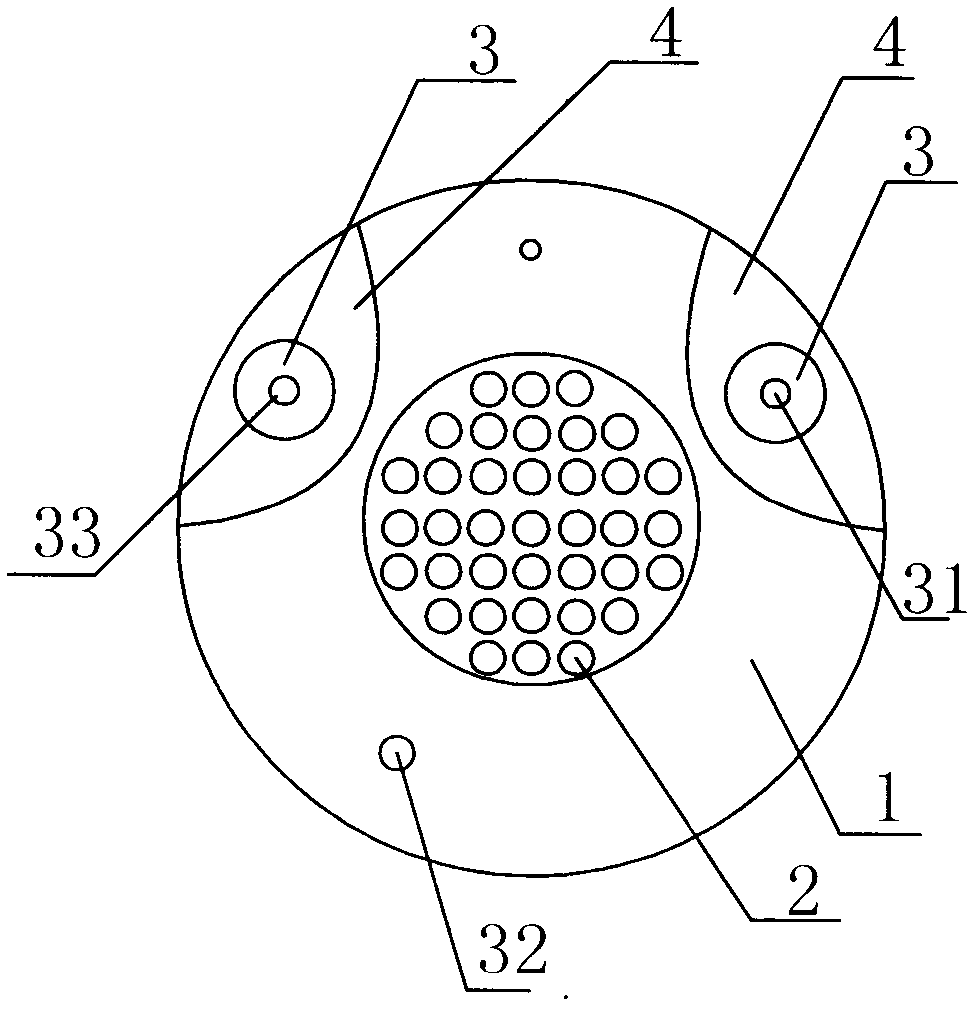

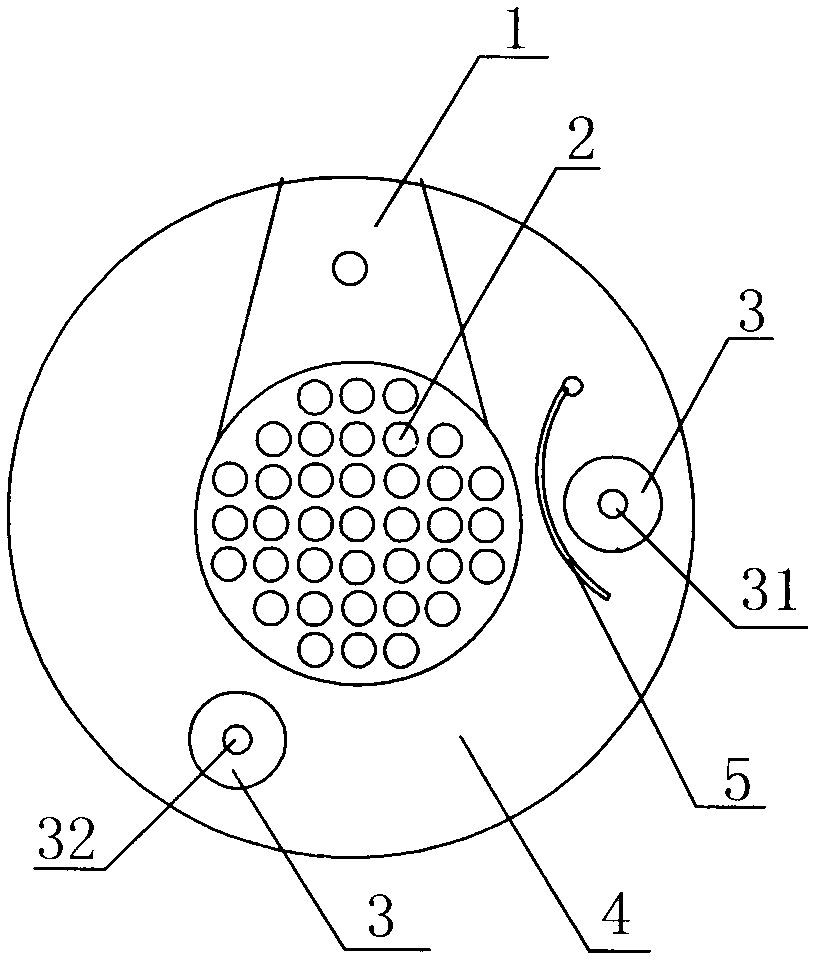

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0013] The ionization chamber of the photoionized gas detector based on the printed circuit board technology of the present invention is composed of two identical electrode plates stacked, such as figure 1 and figure 2 As shown, the electrode plate includes a copper layer 1, a central vent hole 2, a pad 3, a ceramic substrate 4, and a ground layer 5. The three pads 3 are respectively provided with a first via hole 31, a second via hole 32, and a third via hole. The via hole 33, the ground layer 5 is located on one side of the first via hole 31, the copper layer 1 and the ceramic substrate 4 surround the central air hole 2, the three pads 3 are located on the ceramic substrate 4, and the opposite sides of the two electrode plates are in contact , the ground layers of the two electrode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com