Heat exchanger

A heat exchanger and heat exchange tube technology, applied in the field of surface coiled tube heat exchangers, can solve the problem of increasing the complexity of system manufacturing and processing, affecting the heat transfer or resistance characteristics of the heat exchanger, and detrimental to the high efficiency and energy saving of the heat exchanger. problems, to achieve the effect of reducing manufacturing and assembly costs, increasing disturbance, and reducing pump power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

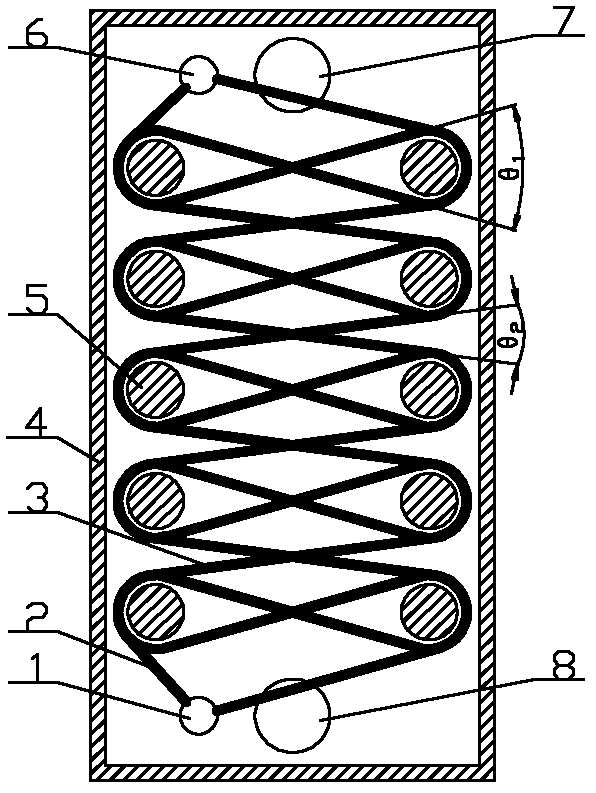

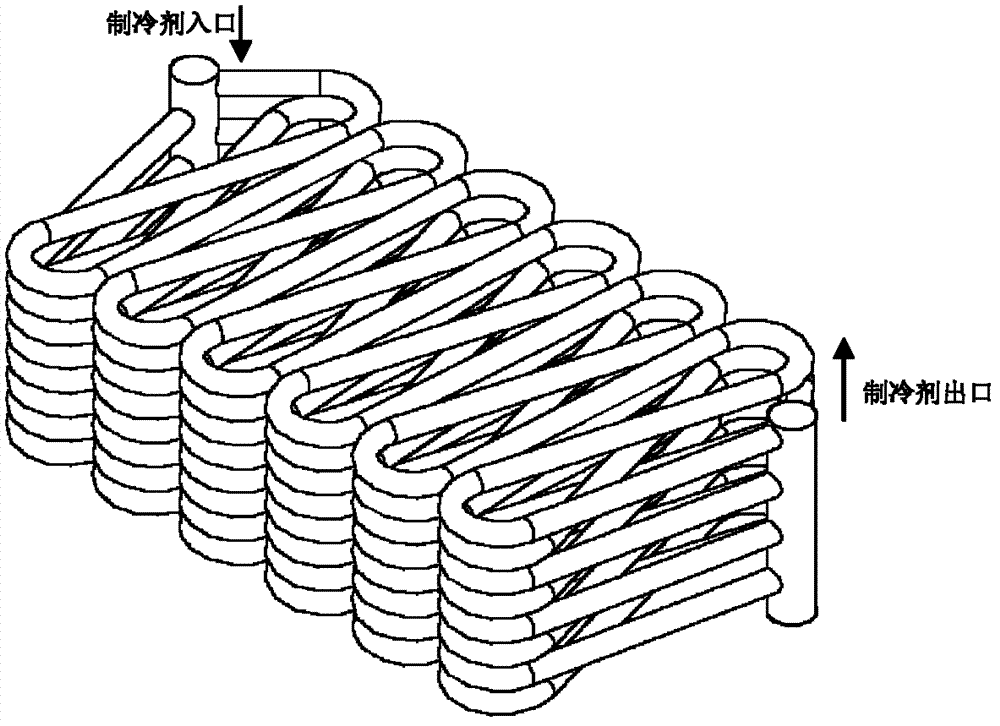

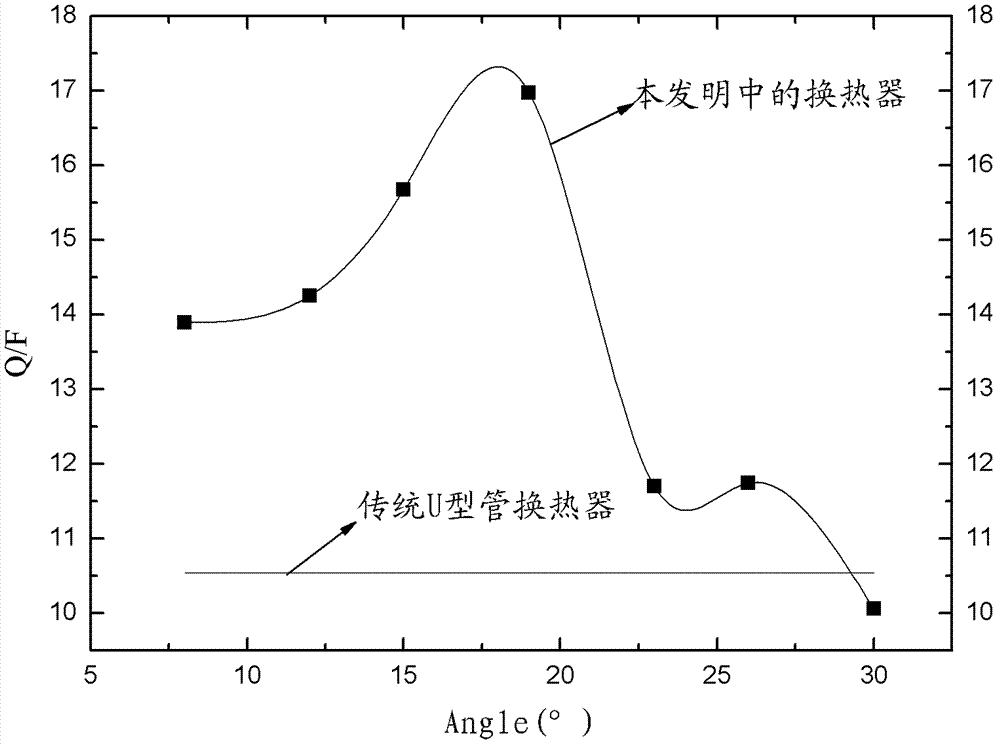

[0018] see figure 1 , 2. The present invention includes a shell 4 provided with a heat exchange working medium inlet 7 and a heat exchange working medium outlet 8, and several layers are arranged in the shell 4 with a refrigerant inlet 1 and a refrigerant outlet 6 without an inner core. Bending tube technology A serpentine heat exchange tube formed at one time. The bend angle of the serpentine heat exchange tube is greater than 180°, and the elbows at both ends are close together (or very close), which greatly reduces the space of the heat exchanger. The volume of the straight pipe section accounts for 70% of the total length. As we all know, when the fluid flows in the straight pipe section, there is only frictional resistance along the way without excessive local resistance caused by the change of flow direction, so the fluid flow in the straight pipe secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com