Pectin oligogalacturonic acid zinc and preparation method and applications thereof

A technology of galacturonic acid and galactose, applied in the field of oligomeric pectin galacturonic acid zinc and its preparation, can solve the problems of difficult popularization and high cost, and achieve easy industrial production, low cost, and reduced feed consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

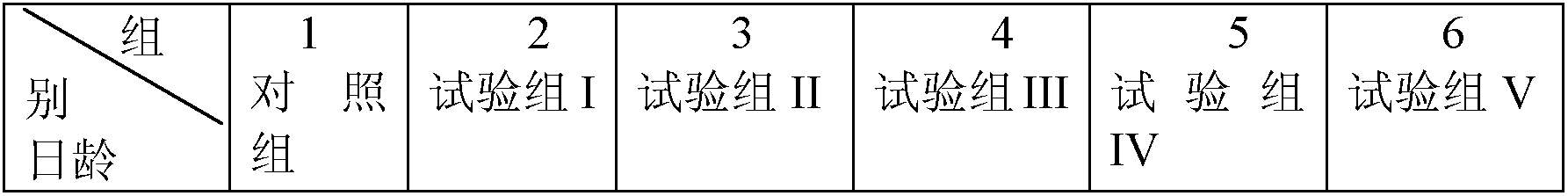

Examples

Embodiment 1

[0017] 1) Take 400g NaOH and dissolve it in 10L concentration of 50% ethanol solution to obtain an ethanol solution of sodium hydroxide, cool the sodium hydroxide solution to 0-5° C. ℃) in 2kg of apple pectin (purchased from Henan Santai Food Industry Co., Ltd., the mass percent content of galacturonic acid is more than 90%) was added to the above-mentioned ethanol aqueous solution of sodium hydroxide, and after reacting for 6 hours, the Overnight (12h), the precipitate was obtained by suction filtration. Add the obtained precipitate to 4L of 50% ethanol aqueous solution, and stir electromagnetically at room temperature to obtain the precipitated ethanol aqueous solution, then use 3M HCL to adjust the pH value of the precipitated ethanol aqueous solution to 1.5, and keep the pH value constant. Stirring was continued for 40 min, and a precipitate was obtained by suction filtration. Respectively with ethanol aqueous solution of hydrochloric acid (the ethanol aqueous solution of...

Embodiment 2

[0024] 1) Weigh 300g KOH and dissolve it in 9L concentration of 40% ethanol aqueous solution to obtain an ethanol aqueous solution of potassium hydroxide, cool the potassium hydroxide ethanol aqueous solution to 0-5°C, electromagnetically stir, and ice-water bath (0-5°C ), add 2kg of citrus pectin (purchased from Sichuan Dayuan Biotechnology Industrial Co., Ltd., the mass percentage of galacturonic acid is more than 90%) to the above-mentioned aqueous ethanol solution of potassium hydroxide, react for 5h, and set at 4°C In the refrigerator overnight, the precipitate was obtained by suction filtration. The resulting precipitate was added to 4L of 40% ethanol aqueous solution, and electromagnetically stirred at room temperature to obtain the precipitated ethanol aqueous solution, and then 3M HCL was used to adjust the pH value of the precipitated ethanol aqueous solution to 2.0, under the condition of keeping the pH value constant Stirring was continued for 30 min, and the preci...

Embodiment 3

[0028] 1) Weigh 300g KOH and dissolve in 9L concentration of 60% ethanol aqueous solution to obtain potassium hydroxide ethanol aqueous solution, cool the potassium hydroxide ethanol aqueous solution to 0-5°C, electromagnetically stir, and ice-water bath (0-5°C ), add 2kg of sunflower pectin (purchased from Pu Lante Pectin Factory, Xingtang County, Shijiazhuang City, the mass percent content of galacturonic acid is more than 90%) in the ethanol aqueous solution of above-mentioned potassium hydroxide, after reacting for 8h , overnight in a refrigerator at 4°C, and a precipitate was obtained by suction filtration. Add the obtained precipitate to 4L of 60% ethanol aqueous solution, and stir electromagnetically at room temperature to obtain the precipitated ethanol aqueous solution, then use 3M HCL to adjust the pH value of the precipitated ethanol aqueous solution to 1.5, and keep the pH value constant. Stirring was continued for 50 min, and a precipitate was obtained by suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com