Isolating liquid for front acid sand fracturing and preparation method thereof

A technology of adding sand to fracturing and spacer fluid, which is applied in the field of spacer fluid, can solve problems such as fracturing fluid gel breaking, achieve the effect of reducing secondary damage and improving construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

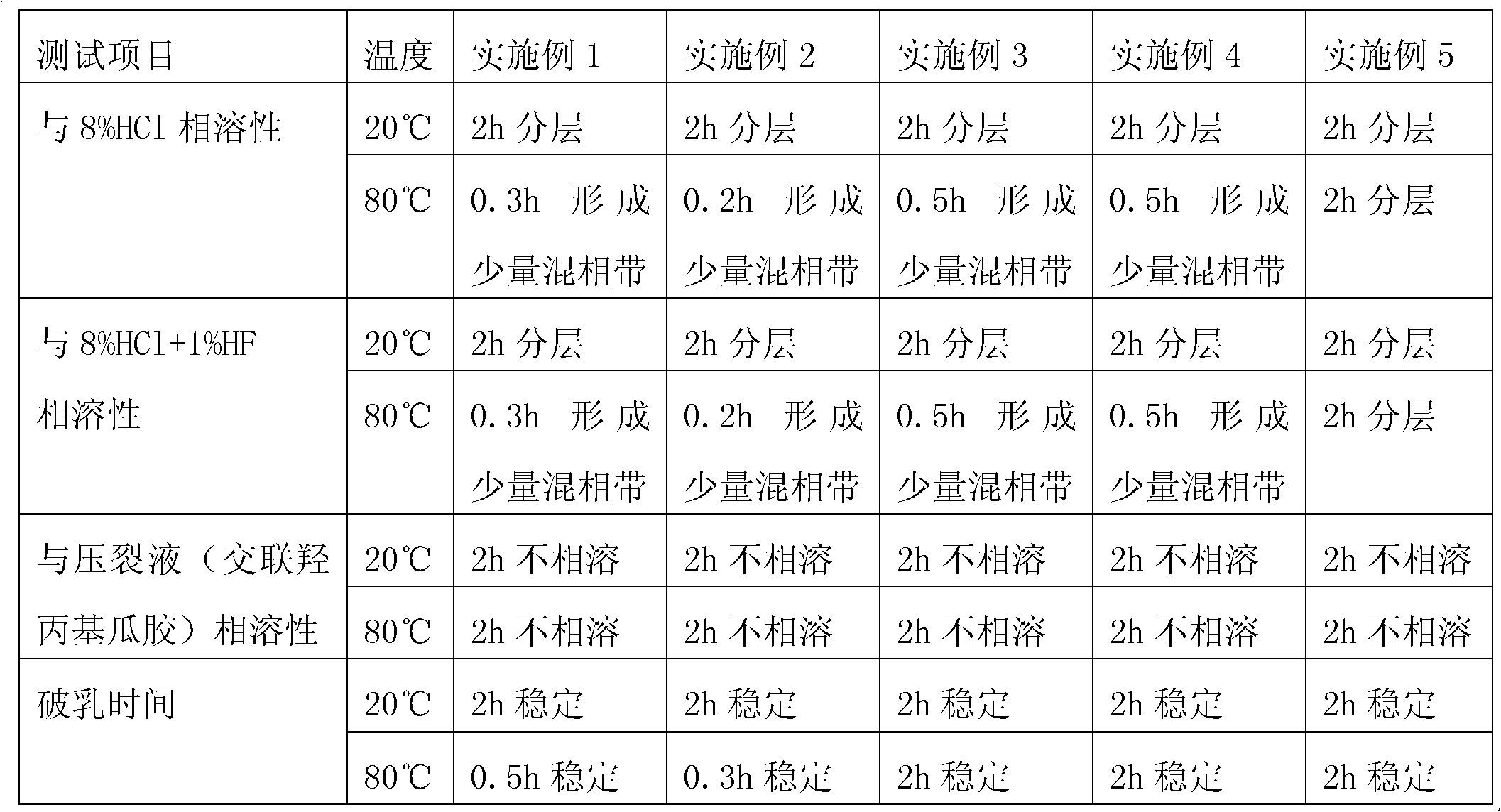

Examples

Embodiment 1

[0039] Take by weighing 50 parts by weight of tributyl phosphate, 1 weight part of ammonium laurylamine acetate, 0.5 parts by weight of polyoxyethylene sorbitan oleate, 0.5 parts by weight of sorbitan oleate, and then weigh 48 parts by weight of water, put the four substances into the agitator, stir at a low speed for 120 seconds, the spacer fluid is not stratified, and the pre-acid and sand fracturing spacer fluid is prepared.

Embodiment 2

[0041] Weigh 50 parts by weight of tributyl phosphate, 1 part by weight of ammonium laurylamine acetate, 0.5 parts by weight of polyoxyethylene sorbitan oleate, 0.5 parts by weight of sorbitan monostearate polyoxygen Vinyl ether, and then weigh 48 parts by weight of water, put the four substances into the agitator, stir at a low speed for 120 seconds, the spacer fluid is not stratified, and the pre-acid and sand fracturing spacer fluid is prepared.

Embodiment 3

[0043] Take by weighing 30 parts by weight of butyl acetate, 1 part by weight of lauryltrimethylammonium chloride, 1 part by weight of polyoxyethylene sorbitan oleate, and then take by weighing 68 parts by weight of water, the four substances Put it into the agitator, stir at low speed for 120 seconds, the spacer fluid is not stratified, and the pre-acid and sand fracturing spacer fluid is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com