Anticoagulation coating and preparation method and application thereof

An anti-coagulation and coating technology, applied in the direction of coating, can solve the problems of poor treatment effect inside the tube wall, unsuitable for large-area use, poor mechanical properties, etc., to improve anti-coagulation performance, reduce operation time and operation. Difficulty, reducing the effect of interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

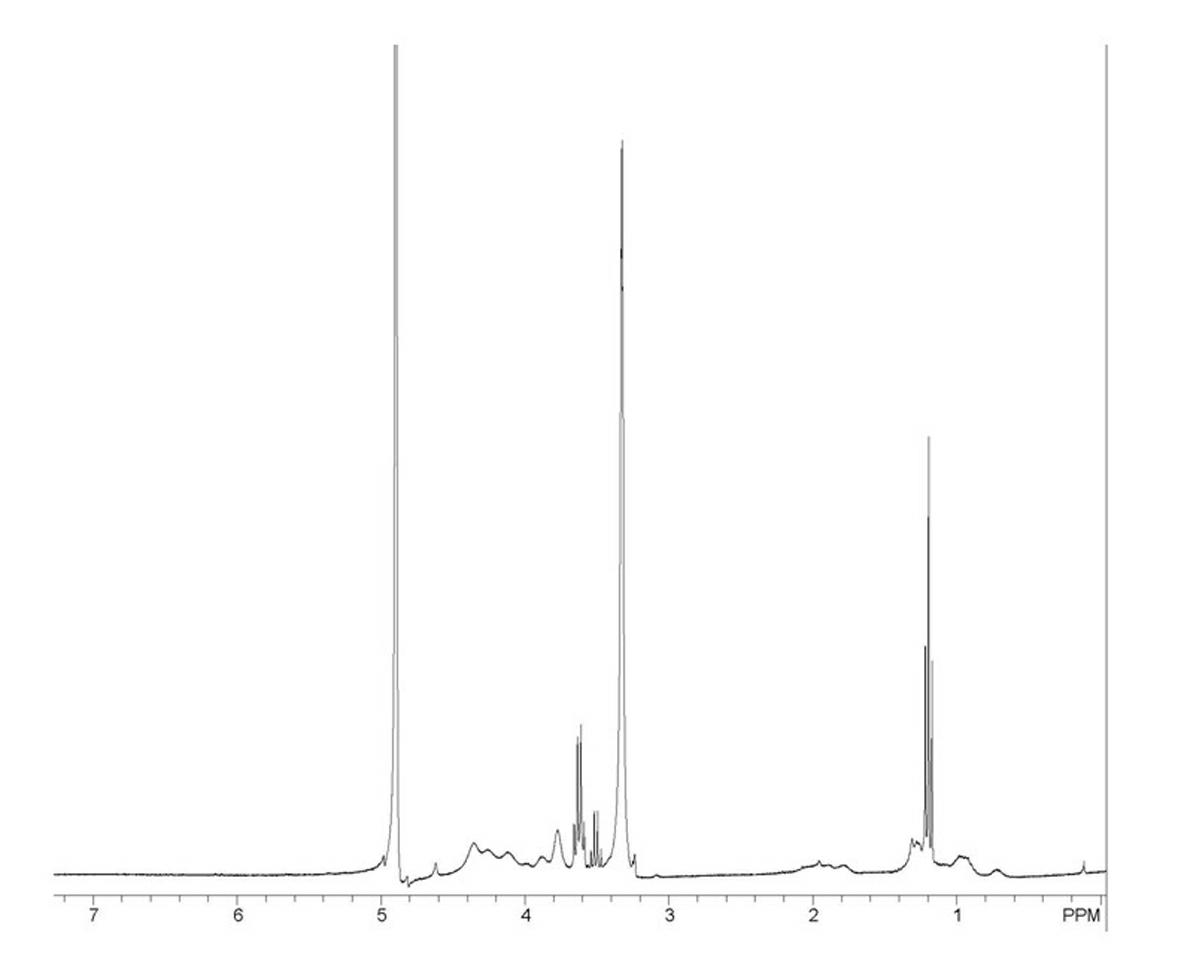

Image

Examples

Embodiment 1

[0038] Weigh 1g (0.004mol) γ-(methacryloxy)propyltrimethoxysilane (KH-570, purified by distillation under reduced pressure), 0.0173g (0.1mmol) N,N,N',N ,'N''-pentamethyldiethylenetriamine (PMDETA), 0.03901g (0.2mmol) ethyl 2-bromoisobutyrate (EBiB) dissolved in 2ml ethanol (after anhydrous purification) into solution, under the protection of inert gas, repeated degassing several times to remove oxygen. Add 0.0072g (0.05mmol) CuBr powder under an inert gas protection atmosphere, and pump again for 10min. Then the reaction system was sealed, heated in an oil bath at 60° C., and reacted for 12 hours.

[0039] The reaction solution was rotary evaporated to remove ethanol, dissolved in THF, and the precipitated catalyst was removed by centrifugation. Then the upper layer solution was separated through a neutral alumina chromatography column to obtain a colorless THF solution. Use a rotary evaporator to distill under reduced pressure at 50°C for 10 minutes to remove the EBiB small-...

Embodiment 2

[0043] 1.5 grams of MPC is added to the reaction system, and 2-bromo-2-methylpropionyloxyethanol, pentamethyldiethylenetriamine, CuCl are mixed according to the ratio of M MPC :M 2-溴代异丁基酰氧基乙醇 :M 五甲基二亚乙基三胺 :M CuCl =50:1:0.2:0.1 was added to the reaction system, degassed, and reacted at 30°C for 24 hours. Under an inert gas atmosphere, add KH570, about 0.6 g, half the amount of MPC, and continue to react for 48 hours. With the activated cation exchange resin as the stationary phase and absolute ethanol as the mobile phase, the catalyst is eluted by column chromatography. The resulting final solution was diluted to 100 mL with ethanol, the number average molecular weight of the copolymer was 12200)

[0044] Immediately immerse the polyethylene membrane into the above solution after irradiating it with plasma, add 0.2 g of triethanolamine, shake it well, let it stand for 5 minutes, take it out and cure it at 100°C for 2 hours, rinse it with PBS buffer solution, and obtain antic...

Embodiment 3

[0046] Add 0.5 g of triethanolamine to the solution obtained in Example 1, immerse the cleaned cellulose membrane in the solution, solidify at 120° C. for 1 hour, and rinse to obtain an anticoagulant cellulose membrane with a coating thickness of 200 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com