Composition of calcium carbonate and organic elastomer and preparation method thereof

A calcium carbonate and elastomer technology, applied in the field of rubber products, can solve problems such as affecting the performance of the composition and being difficult to eliminate, and achieve the effects of good physical and mechanical properties, improved tensile strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Calcium carbonate raw material preparation:

[0035] According to the method described in patent document CN 1631789A instruction manual 3rd page~4th page step (1)~(3), solid content is the calcium carbonate suspension of 6wt%, and the average particle diameter of calcium carbonate particle recorded by specific surface area method is 30nm.

[0036] Composition preparation:

[0037] Take 1.20kg of calcium carbonate suspension and put it into a 2L reactor, stir at 400r / min and heat up to 50°C, then add 0.44kg of SBR-1502 styrene-butadiene latex with a solid content of 20wt%, stir and mix, keep warm for 10min, filter, After dehydration, the filter cake was dried in an oven at 120° C. for 2 hours to obtain the composition of the present invention. The particle distribution of the obtained composition is shown in Table 1. Wherein: the mass percent is: calcium carbonate 45.0%, organic elastomer particles 55.0%.

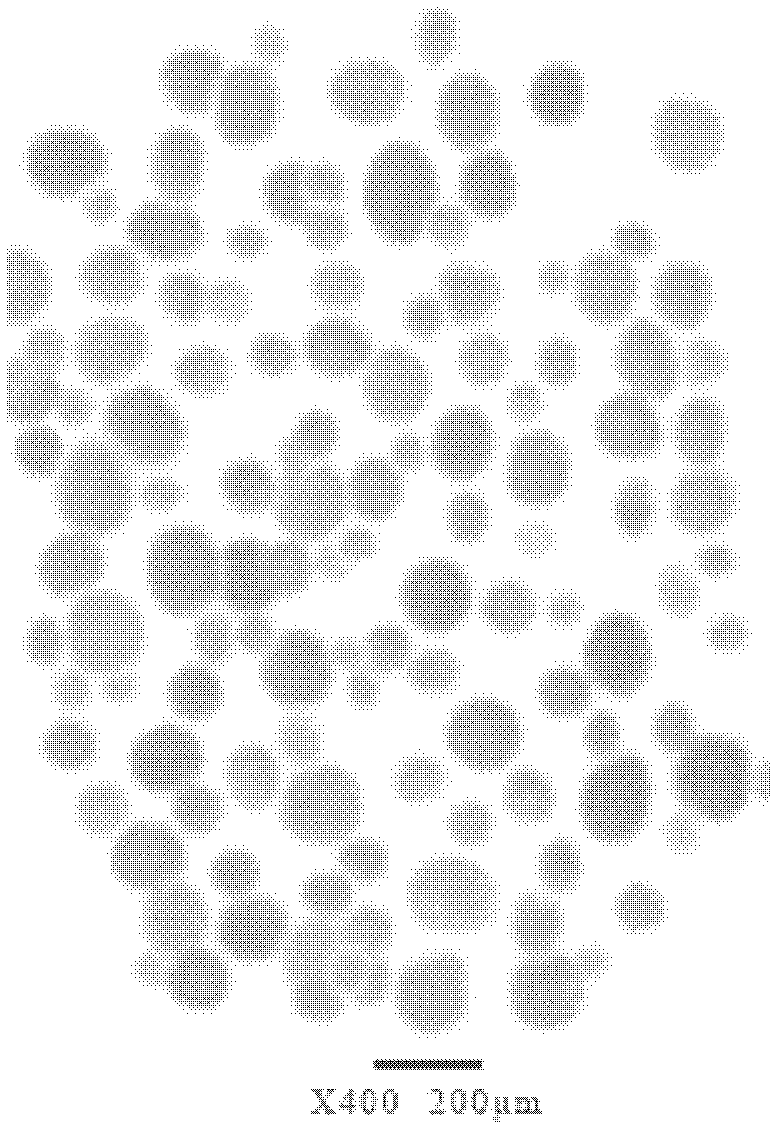

[0038] Application test:

[0039] 100g composition is mixed...

Embodiment 2

[0046] Calcium carbonate raw material preparation:

[0047] According to the same method of embodiment 1, the difference is that the average particle diameter of calcium carbonate is 55nm, and the solid content of calcium carbonate suspension is 11.6wt%.

[0048] Composition preparation:

[0049]Take 1.50kg of calcium carbonate suspension and place it in a 2L reactor, stir at 550r / min and heat up to 60°C, then add 0.18kg of Acronal S400 acrylic latex with a solid content of 55wt%, stir and mix, keep warm for 20min, filter and dehydrate, The composition of the present invention was obtained after the wet material was spray-dried (outlet temperature of tail gas was 85° C.), and the particle distribution of the obtained composition is shown in Table 1. Wherein: the mass percentage is: 63.7% of calcium carbonate, 36.3% of organic elastomer particles.

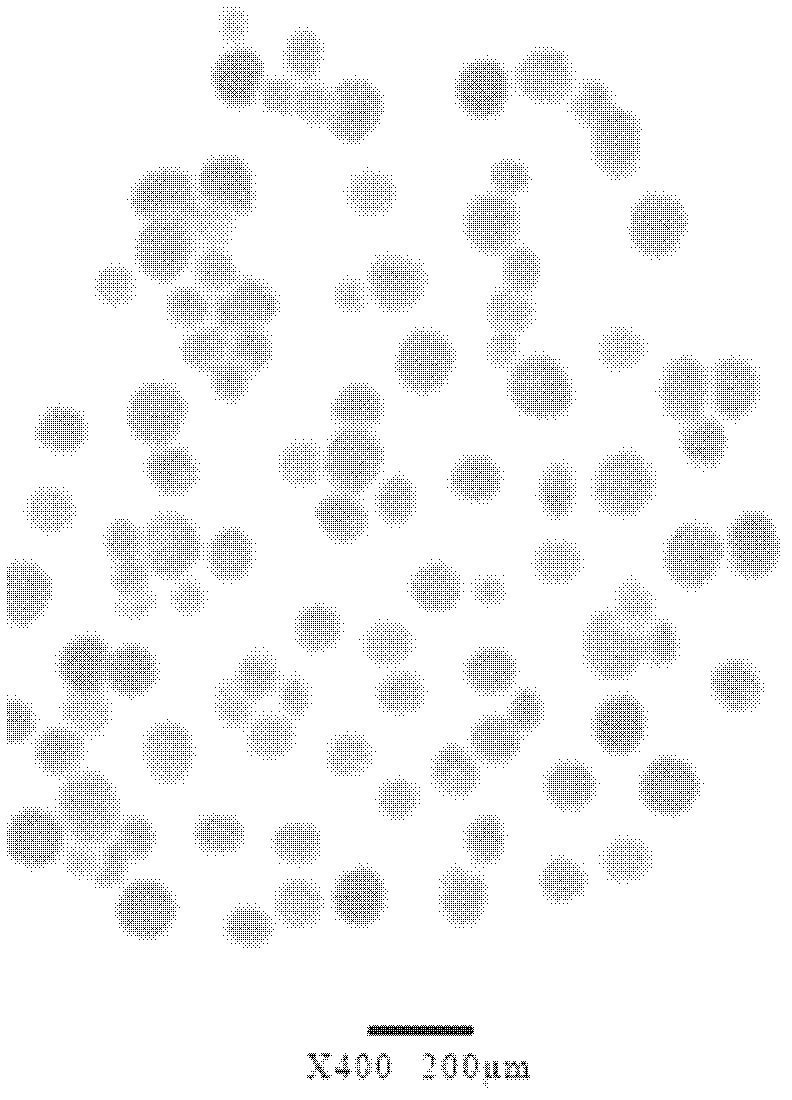

[0050] Application test:

[0051] The 30g composition and 200g grades are PVC powder of SG5, 8g composite lead salt stabilizer,...

Embodiment 3

[0057] Calcium carbonate raw material preparation:

[0058] According to the same method of embodiment 1, the difference is that the average particle diameter of calcium carbonate is 87nm, and the solid content of calcium carbonate suspension is 10.4wt%.

[0059] Composition preparation:

[0060] Put 1.00kg of calcium carbonate suspension into a 2L reactor, stir at 800r / min and heat up to 90°C. Then add 0.52 kg of CRL40-Gx chloroprene latex with a solid content of 5 wt%, cool down and unload after being incubated for 30 minutes, filter and dehydrate, and put the filter cake into a 60°C oven for drying for 2 hours to obtain the composition of the present invention. The particle distribution is shown in Table 1. Wherein: the mass percentage is: calcium carbonate 80.0%, organic elastomer particle 20.0%.

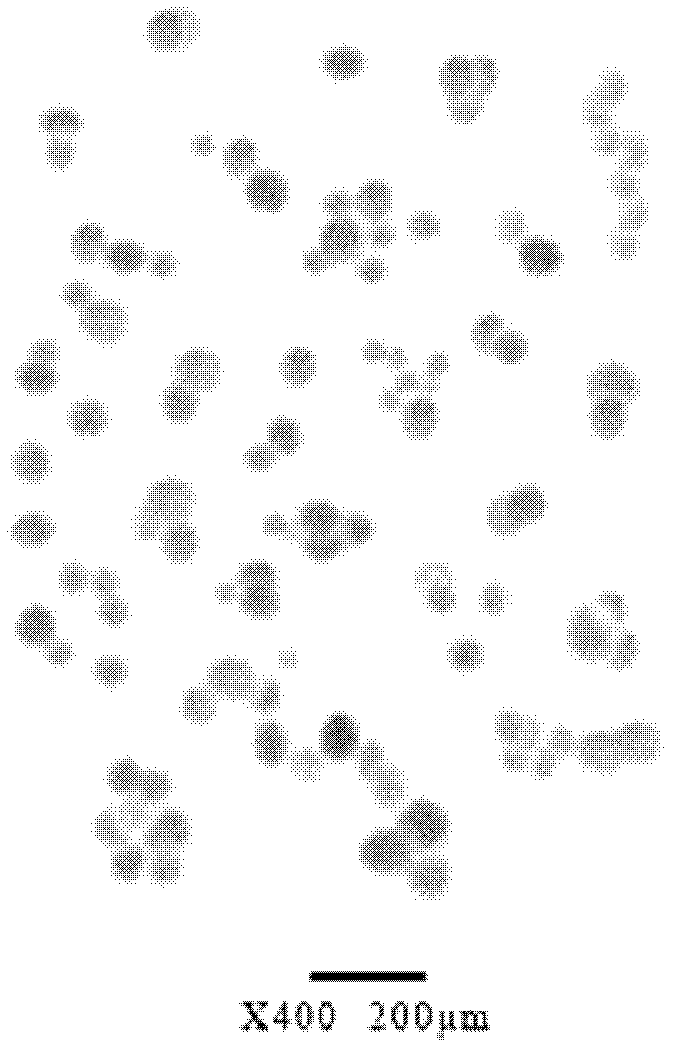

[0061] Application test:

[0062] Heat 200g of Tepco 70# asphalt at 150°C until it flows completely, then add 10g of the composition, stir at a low speed for 20 minutes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com