Ultrasonic-microwave synergic extraction method of chondroitin sulfate

A technology of chondroitin sulfate and ultrasound, applied in the field of ultrasonic-microwave collaborative extraction of chondroitin sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

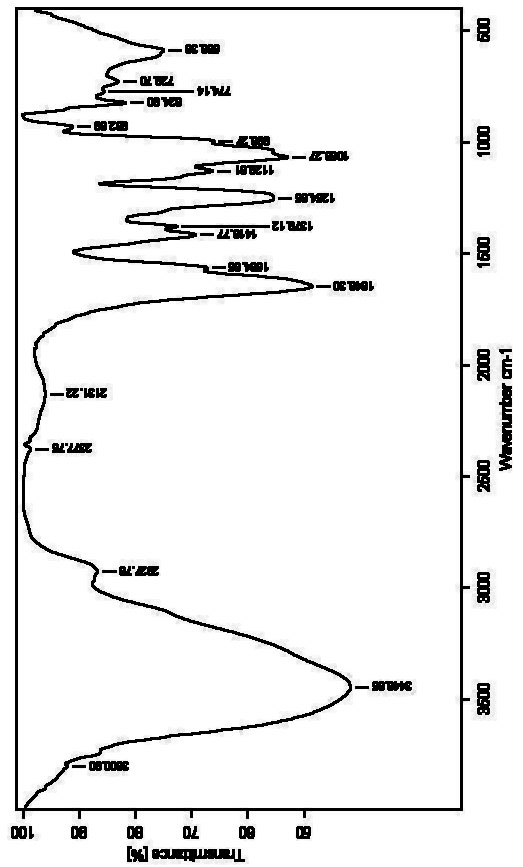

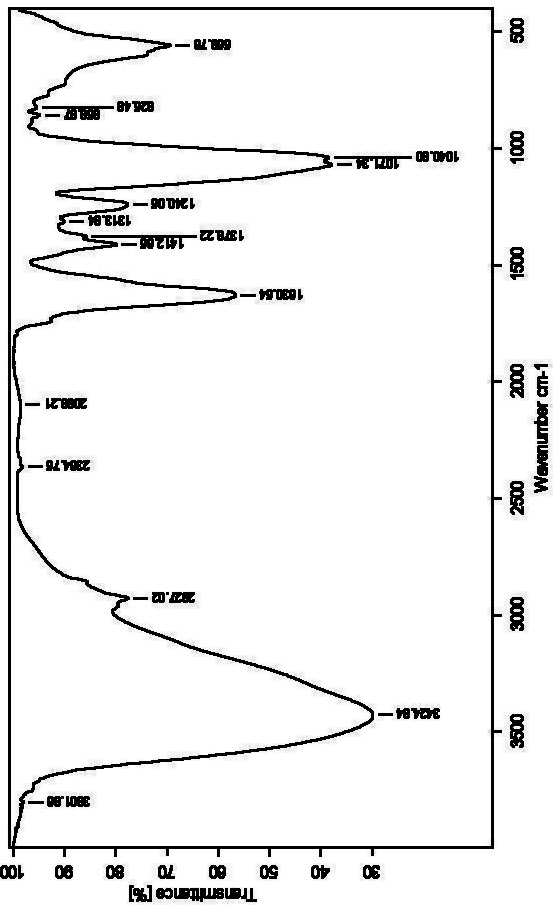

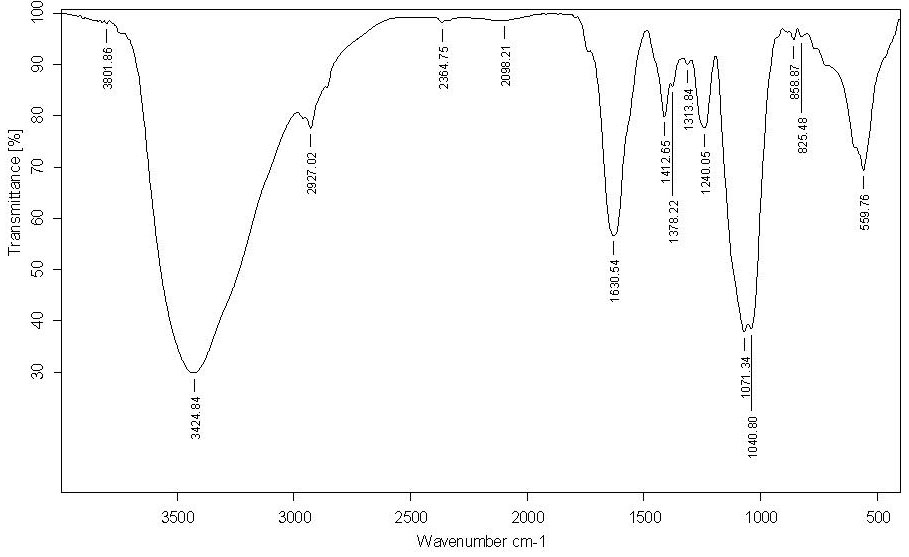

Image

Examples

Embodiment 1

[0029] Cook the leftovers of tilapia (including fish head, fins and fish tails) in a water bath at 80°C for 20 minutes, after cleaning, dry them at 60°C, and after crushing, add volume percent to the leftovers powder Concentration is 99% acetone, the weight of adding acetone is 4 times of the leftover powder weight, after fully stirring, let it stand for 20min to degrease, then pass through a 60 mesh sieve to obtain fish bone powder; accurately weigh 5.000g fish bone powder, and then Add 300g of NaOH solution with a volume percentage concentration of 2% to the fish bone powder; extract the mixture of fish bone powder and NaOH solution in an ultrasonic-microwave collaborative extraction apparatus, and set its parameters as: ultrasonic wave 50w, microwave 200w, extraction time 120s; after the extraction is completed, extract the extract in a 60°C water bath for 30 minutes, filter to obtain 294g of extract; after the extract is naturally cooled to room temperature, adjust the pH o...

Embodiment 2

[0031]Cook the leftovers of tilapia (only fish heads) in a water bath at 70°C for 15 minutes, after cleaning, dry them at 55°C, and after crushing, add 99% vol. Acetone, the weight of adding acetone is 5 times of the leftover powder weight, after fully stirring, let it stand for 30min to degrease, then pass through a 50-mesh sieve to obtain fish bone powder; accurately weigh 4.000g fish bone powder, and then pour it into the fish bone powder Add 280g of NaOH solution with a concentration of 1% by volume; extract the mixture of fishbone powder and NaOH solution in an ultrasonic-microwave cooperative extraction apparatus, and set its parameters as follows: ultrasonic wave 40w, microwave 300w, extraction time 90s; after the extraction is completed , the extract was leached in a 50°C water bath for 20 minutes, filtered to obtain 272g of extract; after the extract was naturally cooled to room temperature, the pH of the extract was adjusted to 5, and then 5.6g of complex protease was...

Embodiment 3

[0033] Cook the leftovers of tilapia (including fish head, fins and tails) in a water bath at 75°C for 18 minutes, after cleaning, dry them at 50°C, and after crushing, add volume percent Concentration is 99% acetone, the weight of adding acetone is 4.4 times of the leftover powder weight, after fully stirring, stand still for 15min to degrease, then pass through a 55 mesh sieve to obtain fish bone powder; accurately weigh 5.000g fish bone powder, and then Add 200g of NaOH solution with a volume percentage concentration of 3% to the fish bone powder; extract the mixture of fish bone powder and NaOH solution in an ultrasonic-microwave cooperative extraction apparatus, and set its parameters as: ultrasonic wave 30w, microwave 60w, extraction time 270s; After the extraction is completed, extract the extract in a 70°C water bath for 40 minutes, filter to obtain 194g of extract; after the extract is naturally cooled to room temperature, adjust the pH of the extract to 7, and then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com