Preparation method of articaine hydrochloride

A technology of articaine hydrochloride and concentrated hydrochloric acid, applied in the field of preparation of articaine hydrochloride, can solve the problems of insufficient product purity and many impurities, and achieve the effects of high product yield, reduction of industrial pollution and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation of embodiment 1 articaine hydrochloride

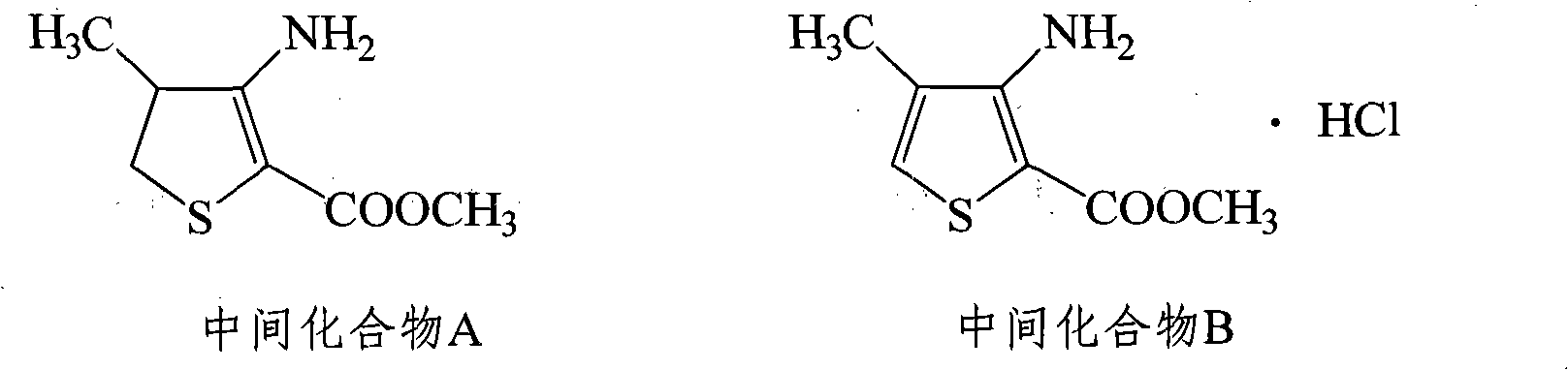

[0019] 1. Preparation of intermediate compound B

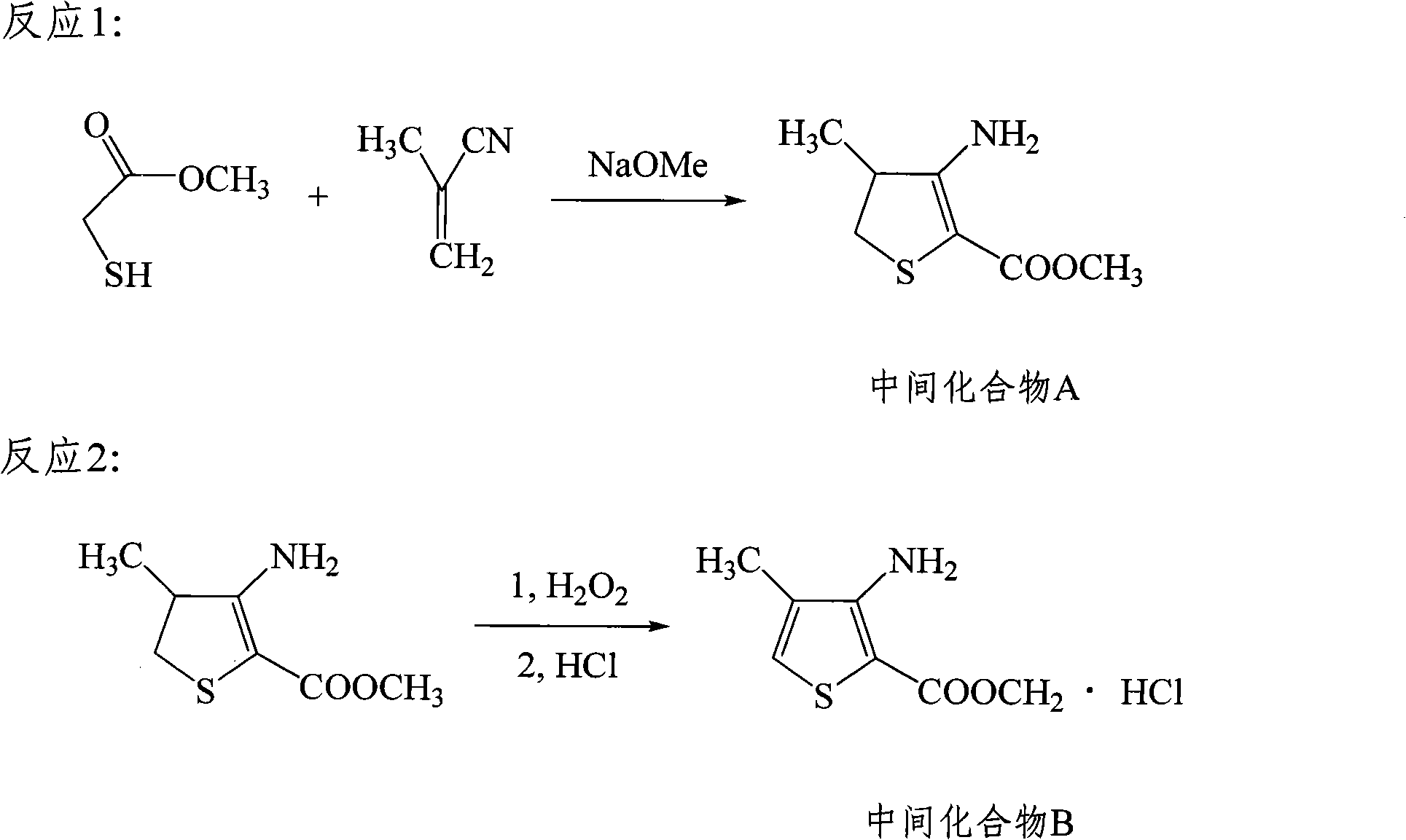

[0020] synthetic route:

[0021]

[0022] Add 12.5L of a mixed solution of sodium methoxide and methanol (prepared from 1kg of sodium metal) into the reaction kettle, control the temperature at 4°C and stir, then add 3.3L of methyl thioglycolate and 3.2L of 2-methacrylonitrile dropwise in sequence. After the dropwise addition, it was naturally raised to room temperature and reacted for 48 hours to obtain an orange-red liquid.

[0023] TLC inspection: silica gel G-254 plate, developer ethyl acetate / petroleum ether=1 / 1, observed under ultraviolet light.

[0024] After cooling to 4°C, concentrated hydrochloric acid was added dropwise to the reaction mixture to adjust the pH to 7 (about 2.8 L) while stirring, and 5.5 L of 30% hydrogen peroxide was added dropwise while stirring. After the addition was completed, the reaction mixture was naturally raised to room t...

Embodiment 2

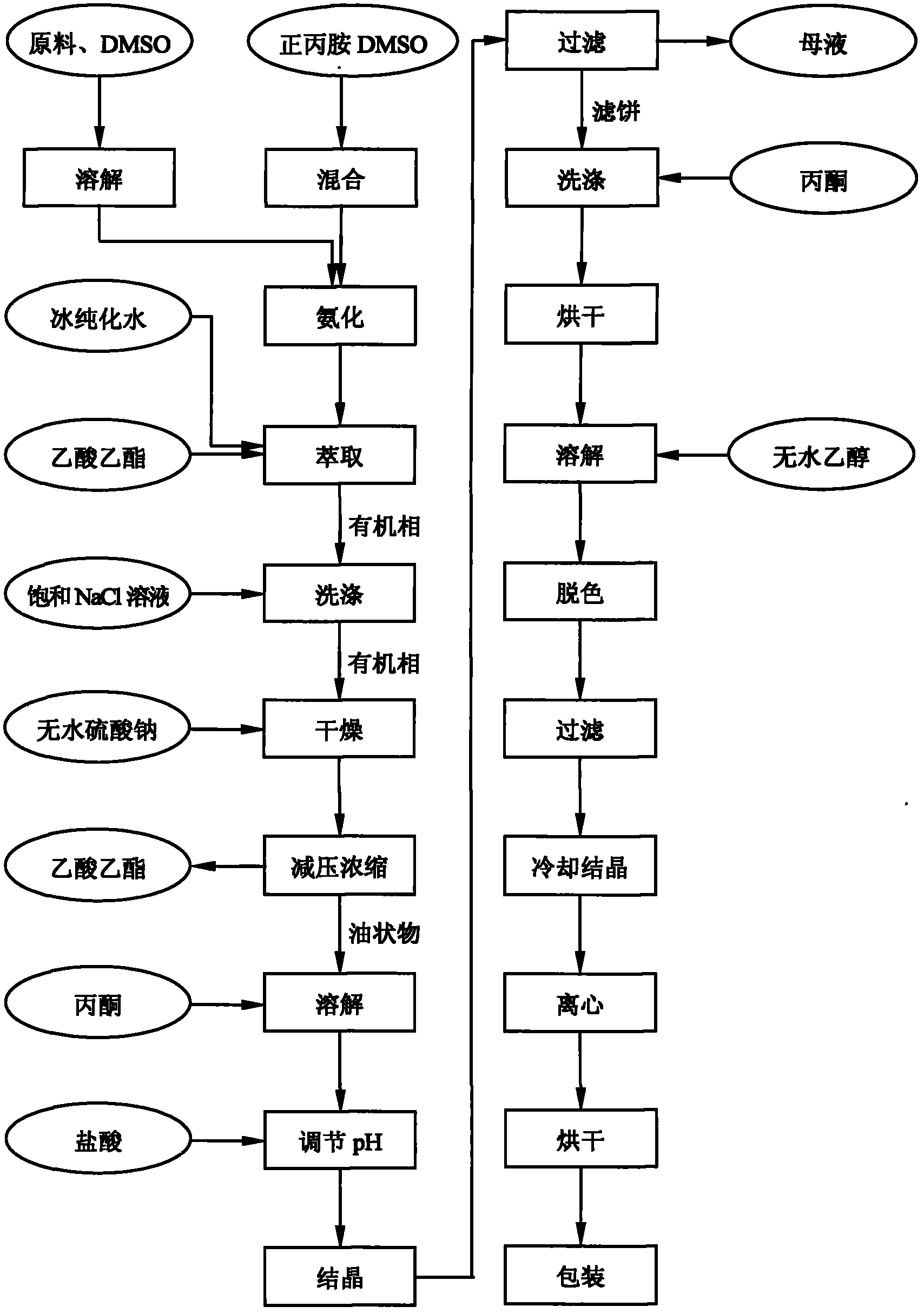

[0052] Example 2 Large-scale production of articaine hydrochloride crude product

[0053] Put n-propylamine and 1 / 3 dimethyl sulfoxide into the hydrogenation reaction kettle, dissolve the intermediate compound C in the remaining dimethyl sulfoxide, and then add the mixture into the autoclave. Add the solution of intermediate compound 3 dropwise under stirring at 0-5°C. After the dropwise addition is complete, keep stirring at natural temperature for 22±2 hours, and control the end point of the reaction with a thin layer. Add ice-purified water, separate and extract with ethyl acetate, wash with saturated brine, and collect the organic phase. After the organic phase was dried with anhydrous sodium sulfate for 10 hours, the sodium sulfate was filtered off and the organic phase was collected. The organic phase was concentrated in ethyl acetate at 60-70°C under vacuum. After concentration, cool, add acetone to dissolve the oil, add concentrated hydrochloric acid dropwise, and ad...

Embodiment 3

[0057] Example 3 Refined large-scale production of articaine hydrochloride

[0058] Put the crude articaine hydrochloride and absolute ethanol into the dissolving pot, heat and dissolve at 65-75°C, add medicinal charcoal after the dissolution is complete, keep warm for 30 minutes for decolorization, and filter into the crystallization tank. Cool to 0-10°C, crystallize for 4 hours and discharge. Centrifugal filtration, drying, packaging. The feed liquid is filtered by a centrifuge, and the wet product is put into a drum oven, dried at 60-70°C for 10 hours, and packaged. (Table 2)

[0059] Table 2 The refinement and inspection of articaine hydrochloride crude product

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com