Three-phase catalytic oxidation preparation technology of soluble chromate

A catalytic oxidation and soluble technology, applied in the direction of chromate/dichromate, etc., can solve the problems that cannot satisfy the diversified production of chromium salt enterprises, and achieve the effect of reduced reaction pressure, high reaction effect, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

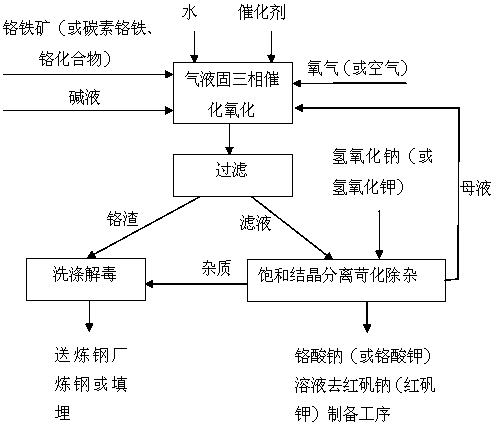

[0030] Such as figure 1 Shown, the present invention provides a kind of technique that three-phase catalytic oxidation prepares soluble chromate, comprises the following steps:

[0031] A. Heat the sodium carbonate solution with a concentration of 20% to 150°C, and then follow the Cr 2 o 3 : Na 2 CO 3 =1:1.5 mass ratio mixed chromite or carbon ferrochrome to form a suspension, and the suspension was passed into the reaction kettle;

[0032] B. Air or oxygen heated to 150°C is continuously fed into the bottom of the reactor through the pipeline;

[0033] C. According to the catalyst in the reactor: Cr 2 o 3 =0.1:100 mass ratio to set the catalyst, the catalyst is a mixture of ferrate, nitrate, manganese oxide, manganate and permanganate, maintain the upper pressure inside the reactor at 0.1 MPa, and maintain the suspension in the reactor The liquid temperature is 150°C, and the gas-liquid-solid three-phase bubbling reaction takes 4 hours to generate soluble sodium chrom...

Embodiment 2

[0037] Concrete steps are basically the same as in Example 1, and the difference is the change of reaction conditions and parameters:

[0038] A. Heat the sodium hydroxide solution with a concentration of 60% to 300°C, and then follow the Cr 2 o 3 : NaOH = 1: 10 mass ratio mixed carbon ferrochromium to form a suspension, the suspension is passed into the reactor;

[0039] B. Air or oxygen heated to 300°C is continuously fed into the bottom of the reactor through the pipeline;

[0040] C. According to the catalyst in the reactor: Cr 2 o 3 =15:100 mass ratio to set the catalyst, the catalyst is a mixture of manganese oxide, persulfide, peroxide and ferrate, the inside of the reactor is not pressurized, and the temperature of the suspension in the reactor is maintained at 300 ° C. Liquid-solid three-phase bubbling reaction for 0.5 hours to generate soluble sodium chromate crude product and chromium residue;

[0041] D. Obtain pure sodium chromate through filtration, crystall...

Embodiment 3

[0044] Concrete steps are basically the same as in Example 1, and the difference is the change of reaction conditions and parameters:

[0045] A. Heat the sodium hydroxide solution with a concentration of 40% to 50°C, and then follow the Cr 2 o 3 : The mass ratio of NaOH=1:5 is mixed with chromite to form a suspension, and the suspension is passed into the reaction tower;

[0046] B. Continuously input the air or oxygen heated to 50°C into the bottom of the reaction tower through the pipeline;

[0047] C. According to the catalyst in the reaction tower: Cr 2 o 3 =8:100 mass ratio to set the catalyst, the catalyst is a mixture of peroxide, sodium chromate and chromic anhydride, maintain the pressure above the inside of the reactor at 0.5 MPa, and maintain the temperature of the suspension in the reactor at 50 °C, the gas-liquid-solid three Phase bubbling reaction for 6 hours to generate soluble sodium chromate crude product and chromium slag;

[0048] D. Obtain pure sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com