Preparation method of hypereutectic aluminum-silicon alloy casting

An aluminum-silicon alloy and hypereutectic technology, which is applied in the metallurgical field, can solve the problems of reducing the mechanical properties of the hypereutectic aluminum-silicon alloy, limiting the use range of the hypereutectic aluminum-silicon alloy, and deteriorating the machining performance, and is easy to realize. Industrialization, small thermal expansion coefficient, small thermal cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

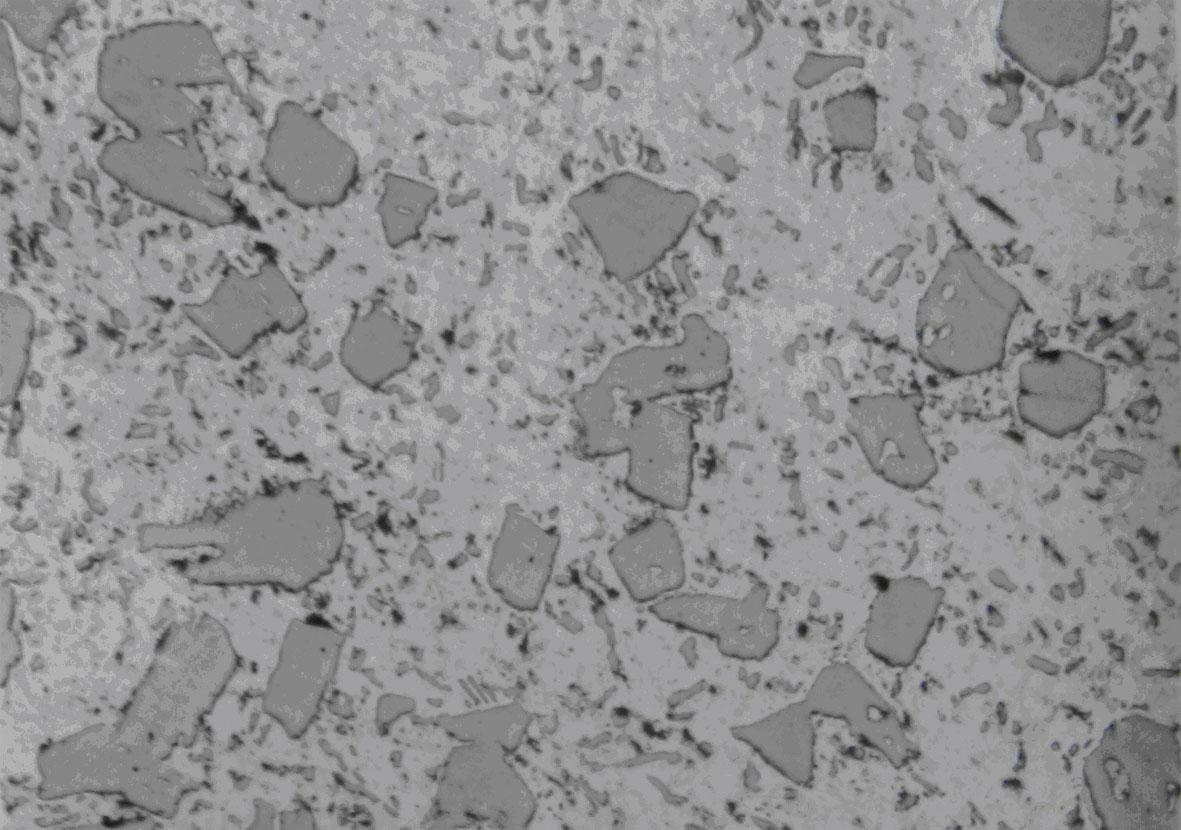

Image

Examples

Embodiment 1

[0016] Preheat the crucible to 400±5°C, put Al28Si alloy, Al50Cu alloy and Al8Ni alloy in the crucible, raise the temperature to 720±5°C, press the metal magnesium into the molten material with a bell jar after all the materials are melted, and the metal The alloy melt is obtained after the magnesium is melted;

[0017] Use a bell jar to press the modifier Cu10P alloy into the alloy melt and stir evenly, and then keep it at 820±5°C for 10 minutes. The amount of modifier added is 0.07% of the total weight of the alloy melt based on the P in the Cu10P alloy;

[0018] ZnCl in a bell jar 2 Press into the alloy melt, the addition amount is 0.20% of the total weight of the alloy melt, degassing at 820±5°C for 5 minutes, then remove the slag, and then cast at 770°C to make a hypereutectic aluminum-silicon alloy billet. The composition by weight percentage is Si20%, Cu2.0%, Ni1.1%, Mg1.6%, impurity 0.6%, and the balance is Al;

[0019] Heat the hypereutectic aluminum-silicon alloy b...

Embodiment 2

[0022] Preheat the crucible to 400±5°C, put Al28Si alloy, Al50Cu alloy and Al8Ni alloy in the crucible, raise the temperature to 720±5°C, press the metal magnesium into the molten material with a bell jar after all the materials are melted, and the metal The alloy melt is obtained after the magnesium is melted;

[0023] Use a bell jar to press the modifier Cu10P alloy into the alloy melt and stir evenly, and then keep it at 820±5°C for 12 minutes. The amount of modifier added is 0.071% of the total weight of the alloy melt based on the P in the Cu10P alloy;

[0024] ZnCl in a bell jar 2 Pressed into the alloy melt, the addition amount is 0.18% of the total weight of the alloy melt, degassing at 820±5°C for 6 minutes, then removing the slag, and then pouring at 780°C to make a hypereutectic aluminum-silicon alloy billet. The composition by weight percentage is Si22%, Cu1.0%, Ni1.6%, Mg1.0%, impurity 0.5%, and the balance is Al;

[0025] Heat the hypereutectic aluminum-silicon...

Embodiment 3

[0028] Preheat the crucible to 400±5°C, put Al28Si alloy, Al50Cu alloy and Al8Ni alloy in the crucible, raise the temperature to 720±5°C, press the metal magnesium into the molten material with a bell jar after all the materials are melted, and the metal The alloy melt is obtained after the magnesium is melted;

[0029] Use a bell jar to press the modifier Cu10P alloy into the alloy melt and stir evenly, then keep it warm at 820±5°C for 14 minutes, and the amount of modifier added is 0.074% of the total weight of the alloy melt based on the P in the Cu10P alloy;

[0030] ZnCl in a bell jar 2 Press into the alloy melt, the addition amount is 0.16% of the total weight of the alloy melt, degassing at 820±5°C for 7 minutes, then remove the slag, and then cast at 790°C to make a hypereutectic aluminum-silicon alloy billet. The composition by weight percentage is Si21%, Cu1.5%, Ni1.4%, Mg1.2%, impurity 0.5%, and the balance is Al;

[0031] Heat the hypereutectic aluminum-silicon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com