Edge termination with improved breakdown voltage

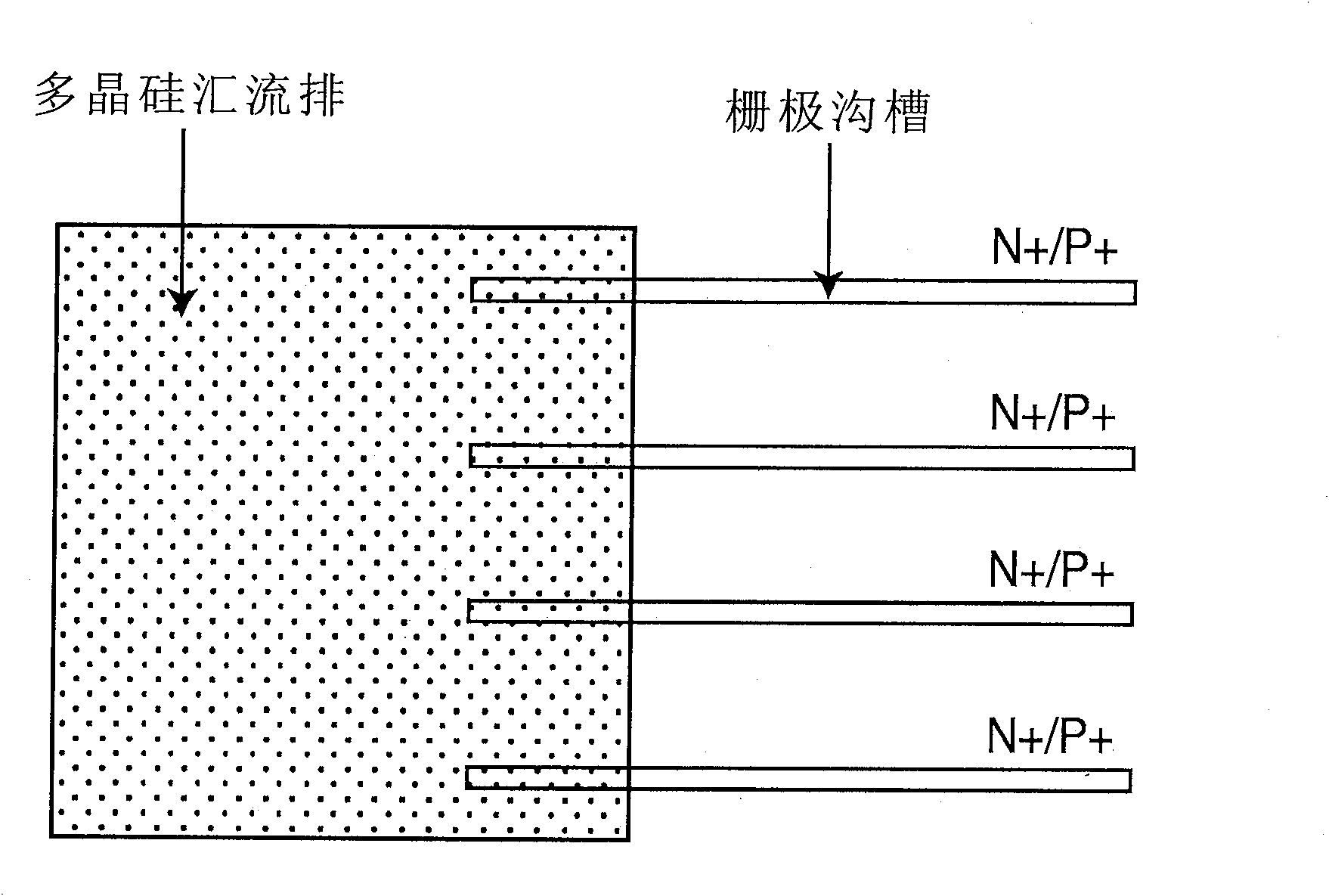

An endpoint, edge technology, applied in the field of edge endpoint area structure, can solve problems such as breakdown and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] Here, many innovative technologies of the application will be described with particular reference to the preferred specific embodiments of the application (by way of example, but not limited thereto). This application describes a number of specific examples, however, the following specific examples should not be taken as limitations of the claims.

[0113] For simplicity and clarity of view, the drawings illustrate the general manner of construction, and descriptions and details of known features and techniques are omitted to avoid unnecessarily obscuring the present invention. In addition, components in the drawings are not drawn according to actual scale, and some areas or components may be drawn enlarged to help understand the embodiments of the present invention.

[0114] It should be considered and noticed that this design is applied to both n-type and p-type metal oxide semiconductor field effect transistors; for the sake of clarity, the structure of n-type metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com