Multilayer body, method for producing same, electronic device member, and electronic device

A manufacturing method and technology of electronic equipment, which are applied in the fields of electrical components, electrical solid devices, chemical instruments and methods, etc., can solve the problem that the gas barrier properties of conductive electrode substrates cannot be said to be satisfactory enough, thin-film, lightweight, flexible The problems of chemical inversion, complicated manufacturing process, etc., to achieve the effects of excellent interlayer adhesion, excellent gas barrier properties, and high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

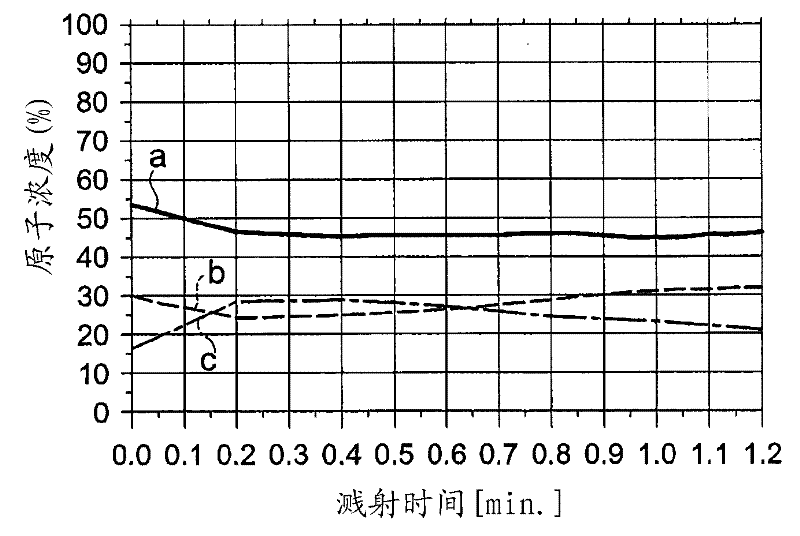

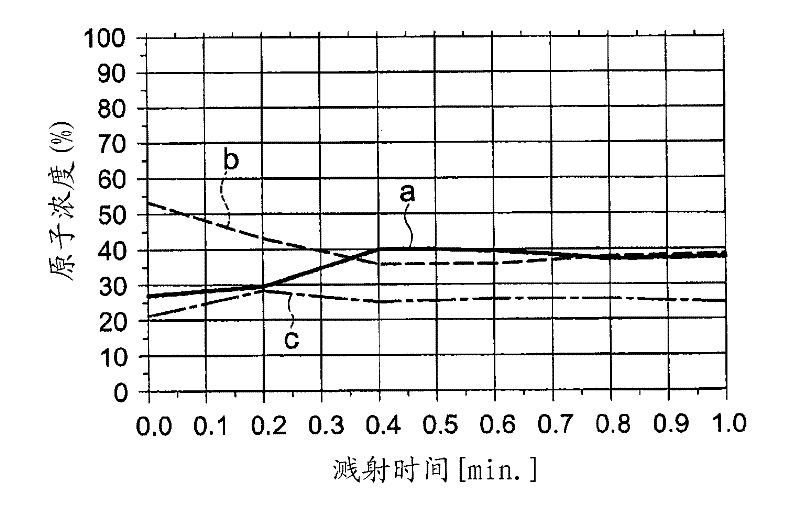

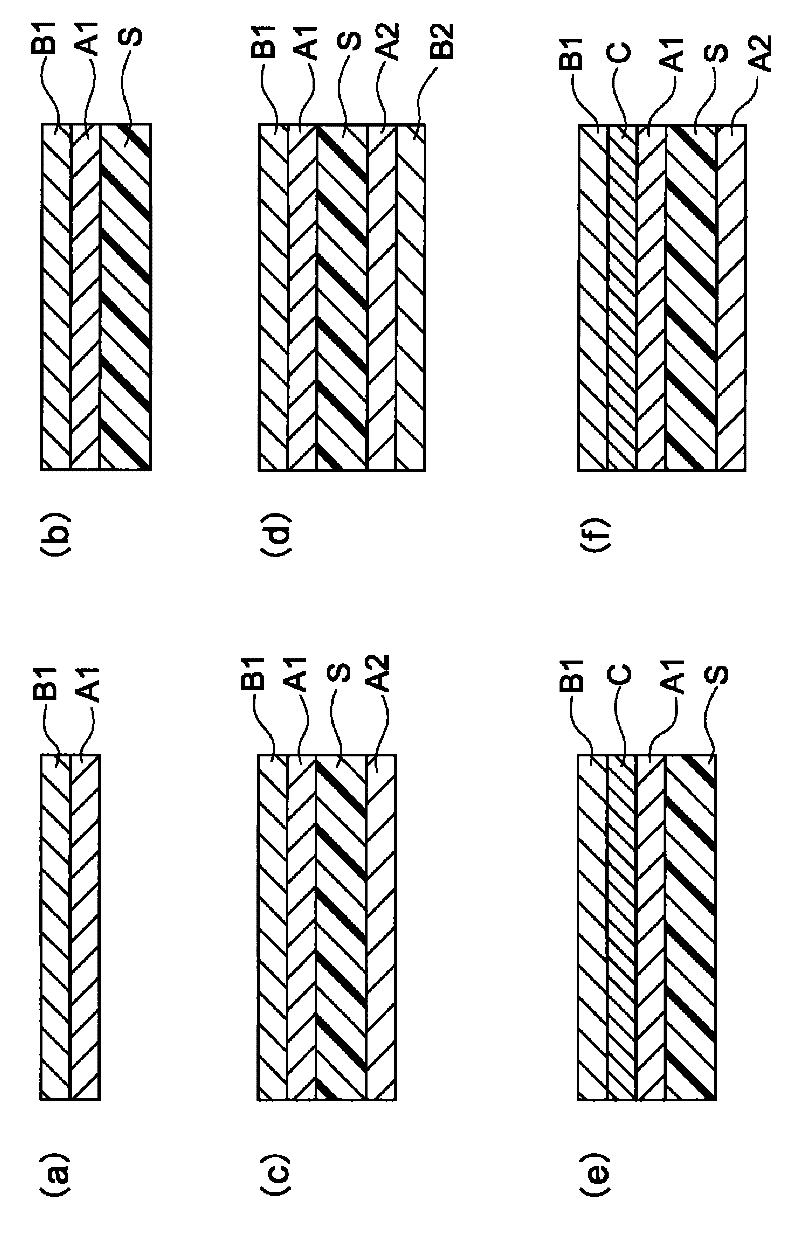

Embodiment 1

[0186]On a polyethylene terephthalate film ("PET38T-300", manufactured by Toray Co., Ltd., thickness: 38 μm) (hereinafter referred to as "PET film") as a base material, use a Meyer bar (Meyer bar) to coat Cloth silicone resin (A) (silicon release agent "KS835", manufactured by Shin-Etsu Chemical Co., Ltd.) mainly composed of polydimethylsiloxane as a polyorganosiloxane compound, and heat at 120°C for 2 minutes to form A layer containing the silicon release agent A with a thickness of 100 nm was obtained to obtain a molded product. Next, use the figure 2 The plasma ion implantation apparatus shown implanted nitrogen into the surface of the layer containing polydimethylsiloxane by plasma ion implantation to produce a molded body 1 .

[0187] The conditions of plasma ion implantation are as follows.

[0188] ? Plasma generating gas: N 2

[0189] ? Duty cycle: 0.5%

[0190] ? Repeat frequency: 1000Hz

[0191] ? Applied voltage: -10kV

[0192] ? RF power supply: frequency 1...

Embodiment 2

[0206] The molded body 2 was fabricated in the same manner as in Example 1 except that argon (Ar) was used as the plasma generation gas.

[0207] Next, in the same manner as in Example 1, on the ion-implanted polyorganosiloxane compound layer of the molded body 2, an ITO film having a thickness of 50 nm as a conductor layer was formed by magnetron sputtering to produce a film having a thickness of 50 nm. A laminate 2 composed of a substrate layer (PET film)-A layer (polyorganosiloxane-based compound layer ion-implanted with argon)-B layer (ITO film).

Embodiment 3

[0209] The compact 3 was produced in the same manner as in Example 1 except that helium (He) was used as the plasma generation gas.

[0210] Next, in the same manner as in Example 1, on the ion-implanted polyorganosiloxane compound layer of the compact 3, an ITO film having a thickness of 50 nm as a conductor layer was formed by magnetron sputtering to produce a film having a thickness of 50 nm. A laminate 3 composed of a substrate layer (PET film)-A layer (polyorganosiloxane compound layer ion-implanted with helium)-B layer (ITO film).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com