LED (light emitting diode) printed circuit board and production method thereof

A technology for printed circuit boards and production methods, which is applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of loss of tool life, high processing costs, and impact on mold life, so as to reduce molding processing costs, The effect of increasing stroke life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

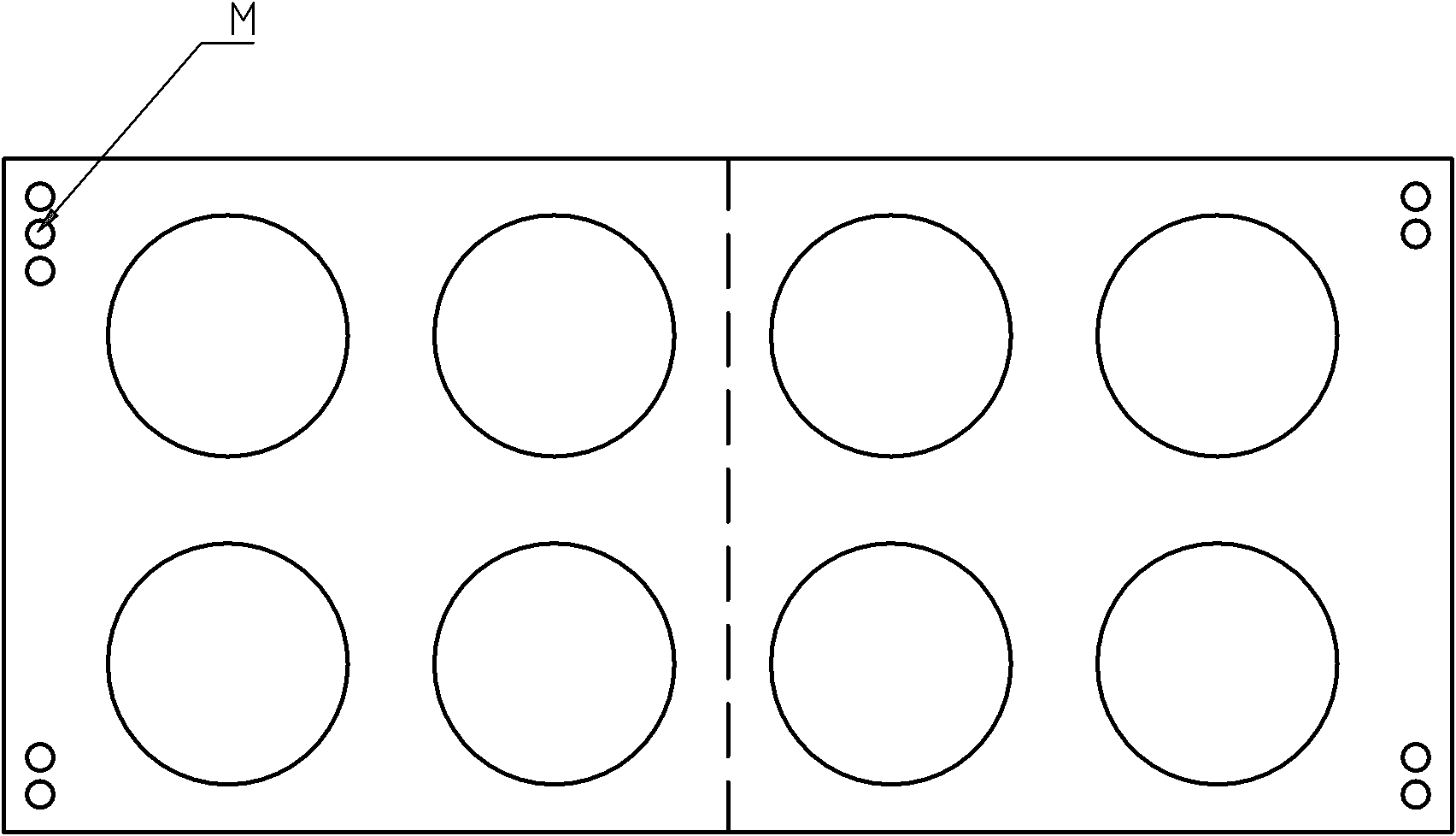

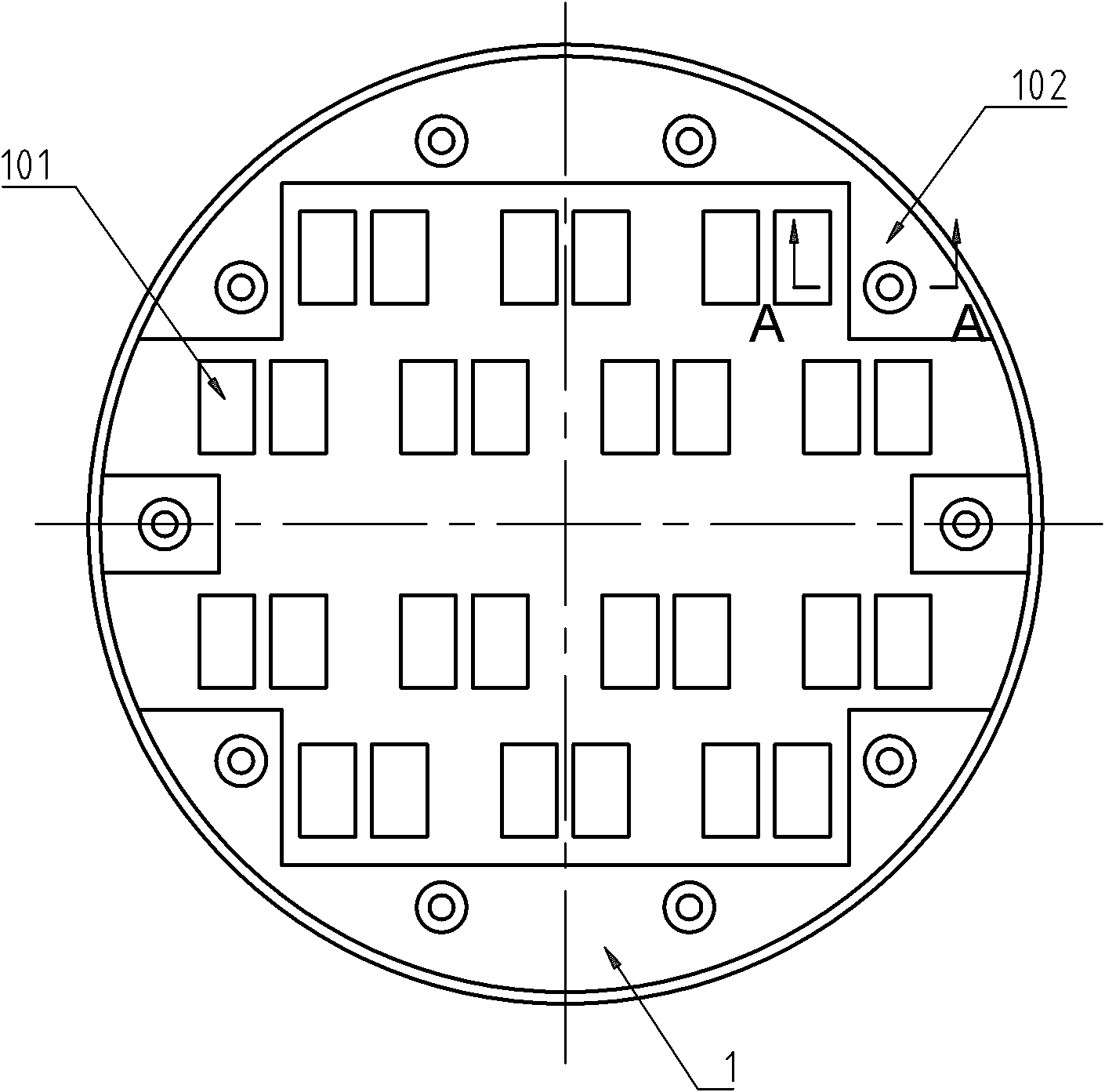

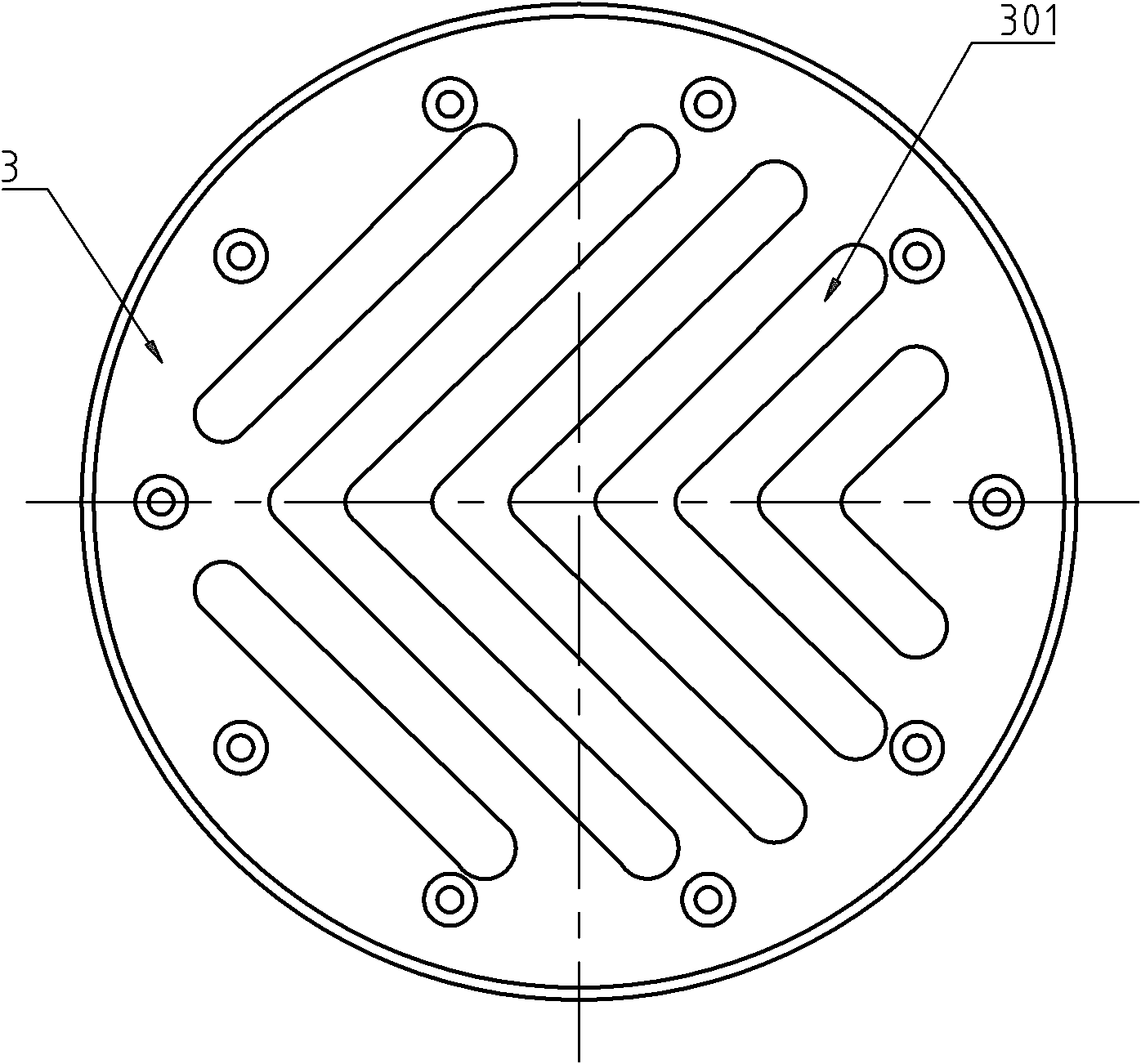

[0023] exist Figure 2 to Figure 4 In the shown embodiment of the LED printed circuit board of the present invention, the LED printed circuit board adopts double-sided copper-clad laminates (such as paper material boards: FR-1, FR-2; glass fiber material boards: CEM-1, CEM-3 , FR-4, etc.) production. The front copper foil 1 includes pads 101, traces (not shown in the figure), and a heat dissipation copper foil 102 insulated from the pads and traces; through-holes 2 pass through the board body, connecting the heat dissipation copper foil 1 and the back copper foil 3. A rivet-shaped heat-conducting copper glue 4 is injected into the through hole, and the rivet-shaped heat-conducting copper glue 4 connects the heat-dissipating copper foil 1 and the back copper foil 3 .

[0024] In this embodiment, the diameter d of the through hole 2 is 0.3 mm. The diameter D of the head of the heat-conducting copper colloid is 0.6 mm for the diameter of the through hole 2 . The heat-conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com