Charge control system

A charge control, charge and discharge technology, applied in the direction of battery temperature control, control device, battery/fuel cell control device, etc., can solve the problems of large battery heat dissipation, battery temperature drop, etc., and achieve the effect of extending the cruising distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

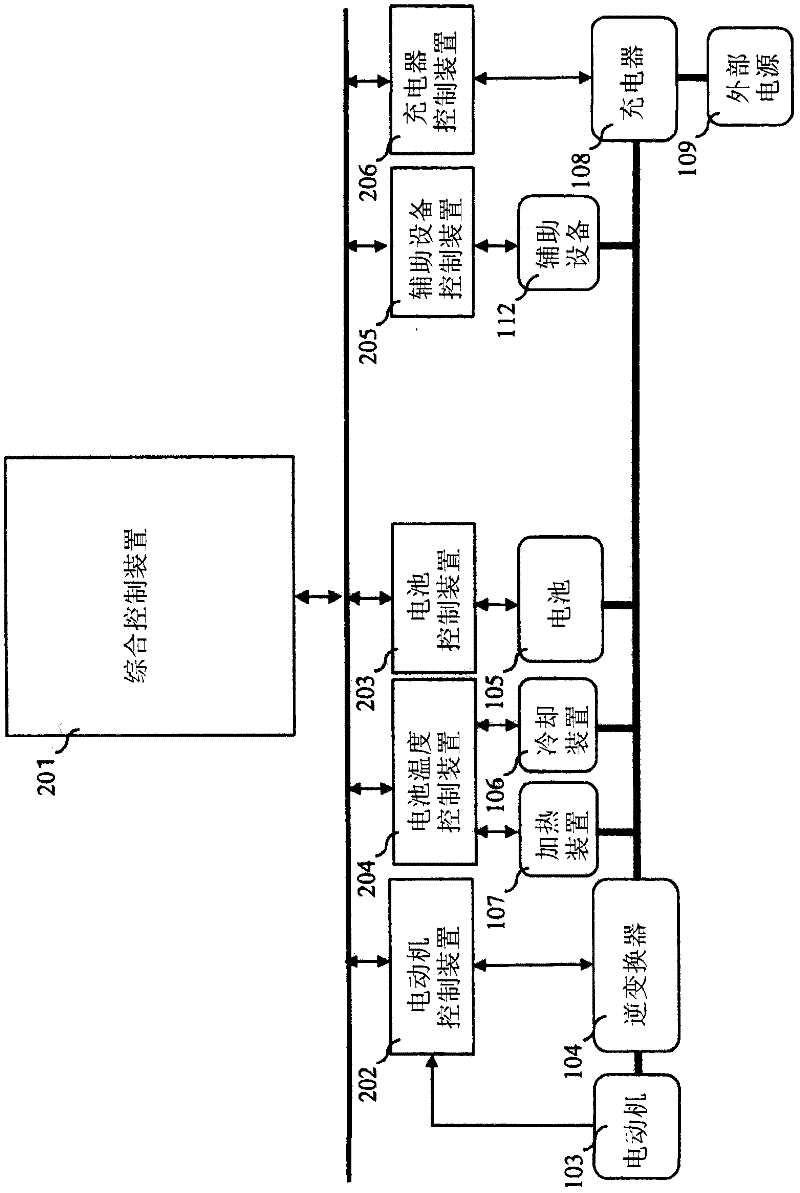

[0060] figure 2 It is a diagram showing the configuration of the charging control system according to the first embodiment of the present invention. This charging control system has: an integrated control device 201; a motor control device 202 for controlling the inverter 104 and the motor 103; a battery control device 203 for controlling the battery 105; a battery for controlling the cooling device 106 and the heating device 107 temperature control means 204 ; auxiliary equipment control means 205 for controlling the auxiliary equipment 112 ; and charger control means 206 for controlling the charger 108 . The control devices described above are connected to each other through a communication network provided in the electric vehicle 101 , for example, CAN (Controller Area Network, Controller Area Network).

[0061] exist figure 2 In the charging control system, the inverter 104, the cooling device 106, the heating device 107, the auxiliary equipment 112 and the charger 108...

no. 2 approach

[0103] Next, a charging control system according to a second embodiment of the present invention will be described. The difference between this embodiment and the above-mentioned first embodiment is that in Figure 4 In the second charging mode of step S402, the battery temperature T is controlled so that the battery temperature T becomes the target battery temperature T_target in consideration of the outside air temperature T_out, rather than the charge-discharge allowable battery temperature lower limit T_min. The target battery temperature T_target can be obtained by adding the offset temperature delta_T determined based on the outside air temperature T_out to T_min.

[0104] Figure 9 means that in the charging control system of the second embodiment of the present invention, instead of Figure 7 A flowchart of the processing performed in the second charging mode by the processing of the flowchart. in, Figure 9 in the flow chart with Figure 7 Likewise, for Figure ...

no. 3 approach

[0127] Next, a charging control system according to a third embodiment of the present invention will be described. The difference between this embodiment and the above-mentioned second embodiment is that in Figure 9 In step S902, the offset temperature delta_T is determined according to the predicted load of the battery 105 and the outside air temperature T_out, and the target battery temperature T_target is calculated.

[0128] Figure 13 It is a diagram showing the configuration of a charging control system according to a third embodiment of the present invention. The charging control system and figure 2 Compared with the above, the difference lies in that a vehicle peripheral information acquisition device 1301 and an information communication device 1302 are provided, and an LUT ( Look Up Table, Look Up Table) 1303.

[0129]Vehicle surrounding information acquiring device 1301 is a device that acquires information on road conditions around electric vehicle 101 as veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com