Temperature adjustment system

A temperature control system and catalyst technology, applied in the field of temperature systems, can solve problems such as accelerating fuel consumption in fuel cells, and achieve the effects of suppressing power consumption, reducing charging frequency, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

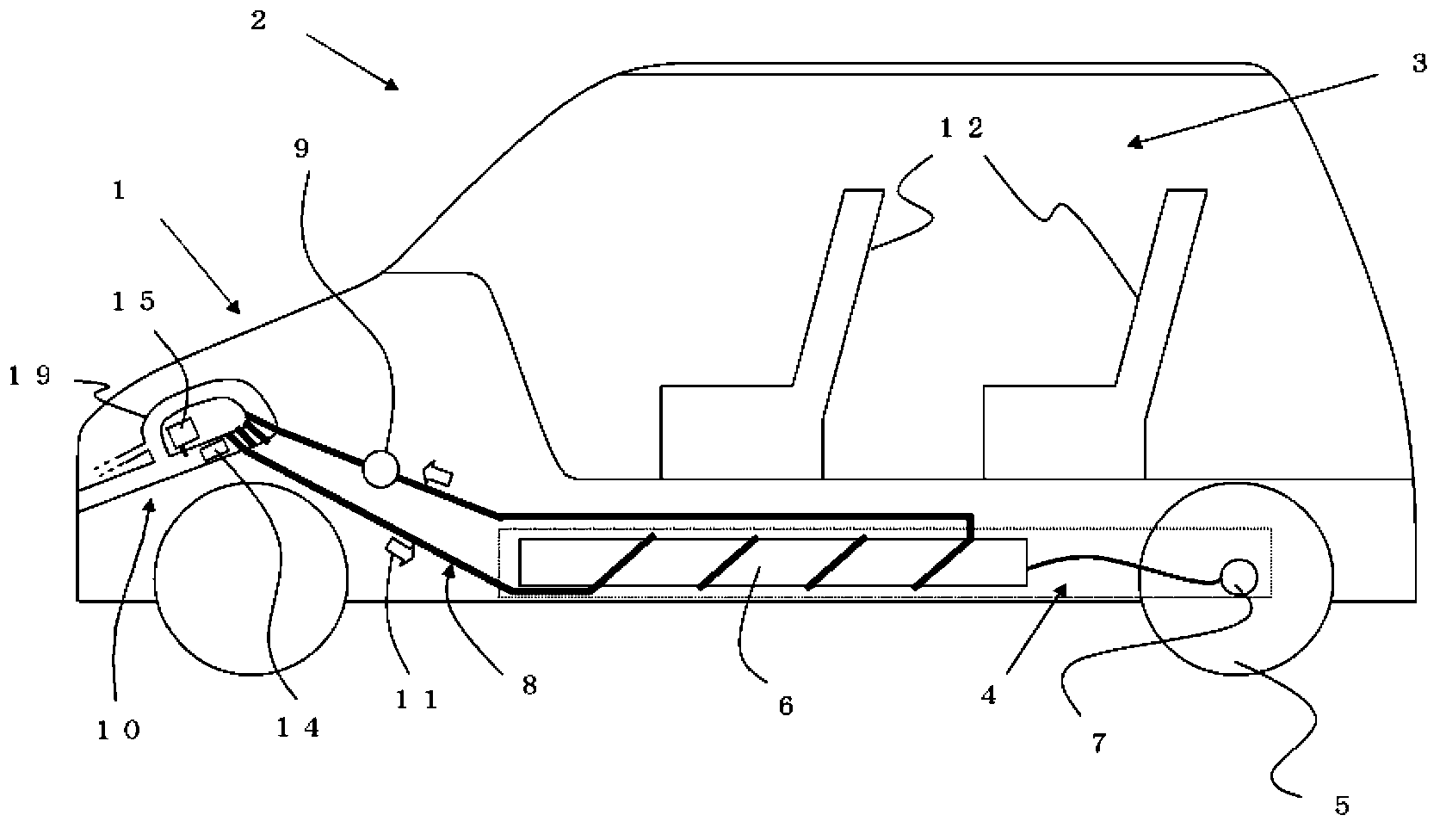

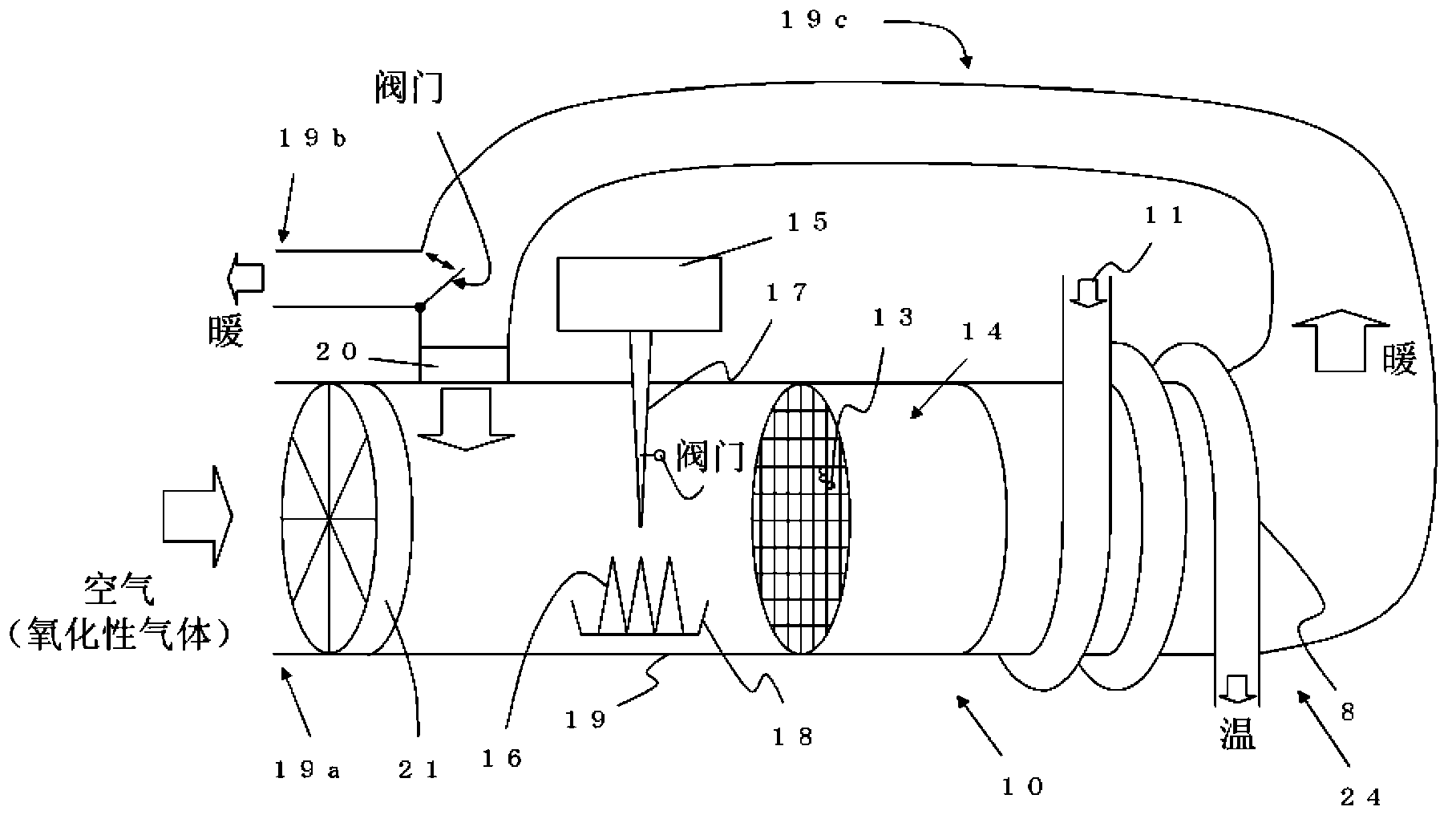

[0161] Carry out the following experiment: prepare to have such figure 2 The temperature control system 1 of the present invention of the catalyst heater 10 shown (in addition, as Figure 8 , In the seat 12 prepared separately, there is a liquid feeding pipe 8), and using this temperature control system of the present invention, in an environment where the outside air is 0 ℃, in the catalyst heater 10, the air and fuel are It reacts on the catalyst 13 and at the same time circulates a part of them and generates heat. The secondary battery 6 and the seat 12 are heated through the liquid feeding pipe 8 or the temperature control duct 27, and at the same time, the air conditioning duct 28 passes through the duct 28 for a specific time. Heat the same space as the carriage and maintain it at a fixed temperature (20℃) (such as Picture 10 system).

[0162] In addition, the secondary battery or the seat is heated so that the temperature is the same as the temperature when the outside ai...

Embodiment 2)

[0172] Except for the same equipment as in Example 1, a thermoelectric element 26 is further arranged.

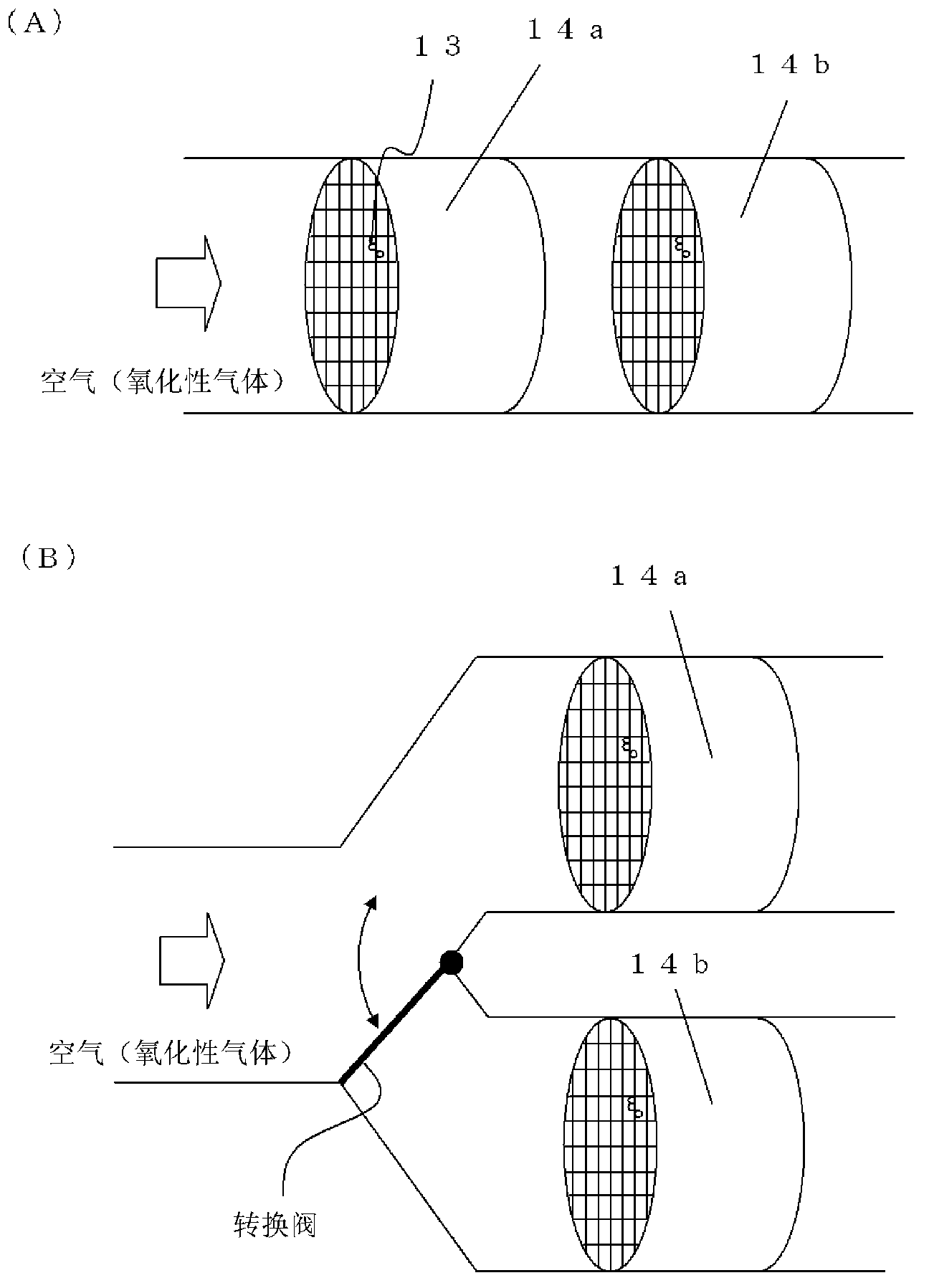

[0173] In addition, thermoelectric elements 26 such as Picture 9 As shown, it is connected to a conduit 19 near the catalyst carrier 14 or downstream thereof. Only supply a small amount of fuel methanol, and try to generate electricity through the Seebeck effect caused by the temperature difference in the above-mentioned parts of the system.

[0174] After measuring the temperature near the catalyst carrier (as the temperature of the catalyst carrier) and the temperature in the downstream area (as the temperature of the reacted gas) at this time, the following results are obtained: Figure 13 Chart.

[0175] by Figure 13 It can be seen that the catalyst carrier itself rises to about 200°C. On the other hand, the gas temperature rose to about 430°C. In addition, using their temperature difference of 200°C or more, the thermoelectric element can effectively store electricity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com