Method for separating low-concentration naphthenic acid in wastewater and preparing naphthenic acid sample

A naphthenic acid, low-concentration technology, applied in the field of separation and sample preparation of low-concentration naphthenic acid in wastewater, can solve problems such as difficulty in evaluating the extraction efficiency of naphthenic acid and difficult determination of non-solvent organic carbon, and achieve good purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

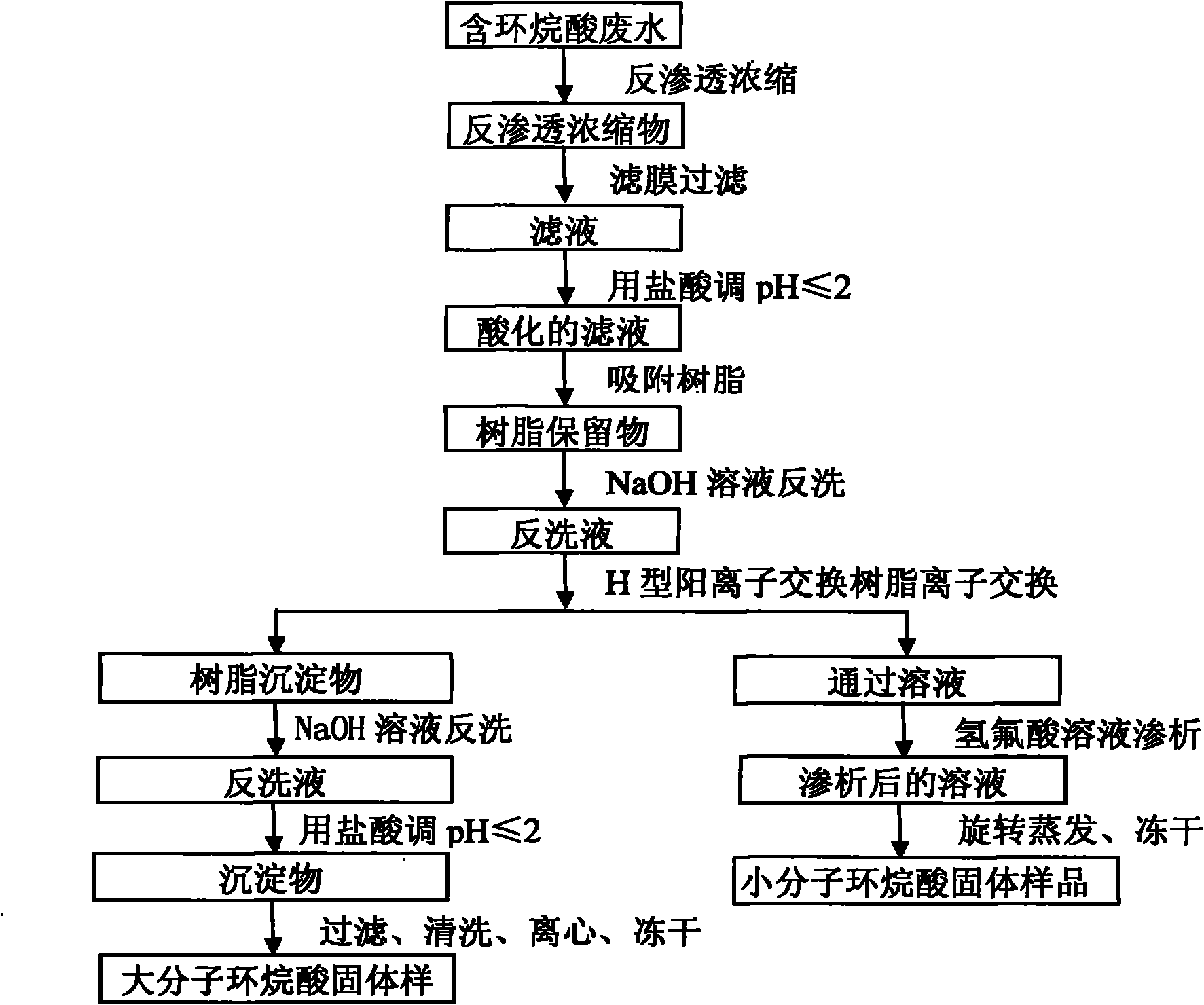

Method used

Image

Examples

Embodiment 1

[0026]Amberlite DAX-8 resin (SUPELCO) was soaked with 0.1mol / L NaOH for 24h, and then washed with deionized water to remove residual NaOH. The washed resin was sequentially extracted by Soxhlet with dichloromethane, acetone and methanol for 16 hours. Put the purified 800mL DAX-8 resin into a glass column with a length of 700mm and an inner diameter of 40mm, and the two ends of the glass column are fixed with glass wool. Next, wash with deionized water, 0.1mol / L NaOH, deionized water, 0.1mol / L HCl and deionized water in sequence until the total organic carbon (TOC) of the eluate is lower than 1.0mg / L.

[0027] MSC H Form cation exchange resin (MTO-Dowex Marathon) was Soxhlet extracted with methanol for 16h and stored in methanol. About 800mL of purified MSC H Form cation exchange resin was loaded into a glass column with the same specifications as the DAX-8 resin column. The resin column was washed sequentially with deionized water, 0.1mol / L NaOH, deionized water, 0.1mol / L HC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com