Three-layer noise reduction drainage pipe and manufacture method thereof

A manufacturing method and drainage pipe technology, which is applied in the field of pipelines, can solve the problems of noise, water flow colliding with the wall of the drainage pipe, no good solution, noise and other problems, and achieve obvious noise reduction effect, good impact strength and Tensile strength, the effect of reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

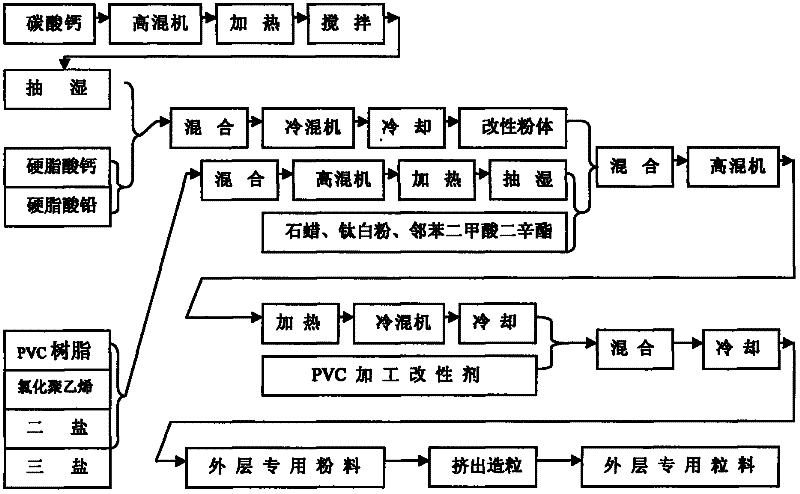

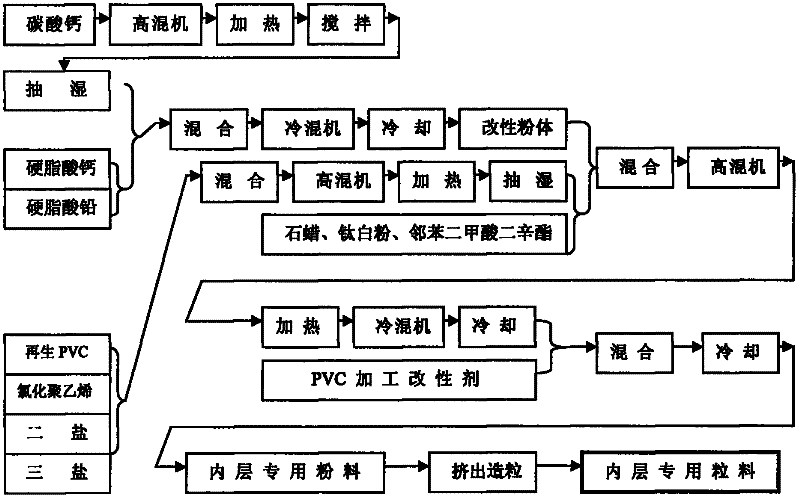

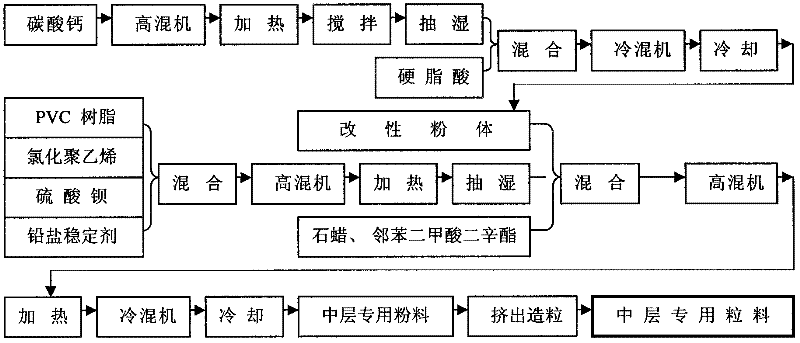

[0069] Impact-resistant outer layer: 100 parts of polyvinyl chloride resin (SG4), 8 parts of chlorinated polyethylene, 2 parts of dibasic lead phosphite, 5 parts of tribasic lead sulfate, 1.2 parts of calcium stearate, lead stearate 1 part, 0.6 parts of paraffin, 1.5 parts of PVC processing modifier (ACR401), 10 parts of activated light calcium carbonate (800 mesh), 2.2 parts of titanium dioxide, 4 parts of dioctyl phthalate. Characteristics of impact-resistant outer layer material selection: The impact-resistant outer layer material is mainly to improve impact resistance. PVC resin is a polar non-crystalline high polymer with strong force between molecules. It is a hard and brittle material; lower impact strength. Chlorinated polyethylene is specially added to the material formula, and hdpe (high-density polyethylene) is used to suspend the chlorinated powder product in the water phase. With the increase of chlorination degree, the original crystallized hdpe gradually becomes...

Embodiment 6

[0092] Embodiment 6 is to directly apply the material of the scheme two in the content of the invention, that is, an expandable polyvinyl chloride composition material, wherein: 100 parts by weight of polyvinyl chloride resin, 17 parts by weight of methacrylic ester polymer, inorganic foaming 18 parts by weight of agent. Directly enter into co-extrusion with outer and inner layer composition materials, and others are all carried out according to embodiment one. After testing, they all meet the requirements of the national standard GB / T 5836.1-2006 "Rigid Polyvinyl Chloride (PVC-U) Pipes for Building Drainage", and the noise reduction effect is similar to the above [Example 4].

[0093] Can draw from above: the optimal proportioning of barium sulfate is 150~300 weight parts, active light calcium carbonate (800 orders) also has certain sound-absorbing ability, but the noise reduction effect of barium sulfate, active light calcium carbonate is strong ( 800 mesh), and appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com