Method for improving alumina dissolution rate in aluminium electrolysis process

A technology of dissolution rate and alumina, which is applied in the field of aluminum electrolysis, can solve the problems of unsatisfactory industries, and achieve the effects of energy saving, lower electrolysis temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

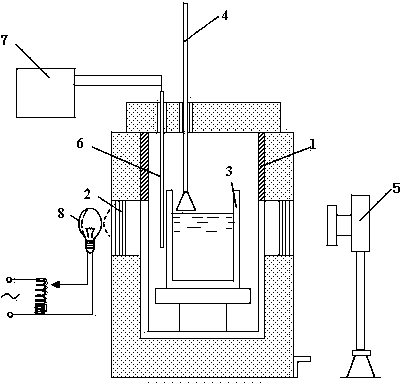

Image

Examples

Embodiment 1

[0024] Add fluorine-carrying aluminum oxide with hydrogen fluoride content of 1wt% to the electrolyte through the feeding tube, the amount added is 1wt% of the total amount of electrolyte, when the alumina added to the electrolyte is completely dissolved and the temperature is stable again, add 1wt% to it again alumina, and so on, until the alumina added to the transparent tank no longer dissolves or the life of the quartz crucible expires. Compared with ordinary alumina (average dissolution time of 10 minutes), the dissolution time of fluorine-loaded alumina (about 6 minutes) is 60% of that of ordinary alumina.

Embodiment 2

[0026] The hydrogen fluoride content is 0.5wt% fluorine-loaded alumina is added to the electrolyte through the feeding tube, the addition amount is 1wt% of the total amount of electrolyte, when the alumina added to the electrolyte is completely dissolved and the temperature is stable again, add 1wt to it again % alumina, and so on, until the alumina added to the transparent tank no longer dissolves or the life of the quartz crucible expires. Compared with ordinary alumina (average dissolution time of 10 minutes for a single time), the dissolution time of fluorine-loaded alumina (about 7 minutes) is 70% of that of ordinary alumina.

Embodiment 3

[0028] Add 4wt% hydrogen fluoride-loaded aluminum oxide to the electrolyte through the feeding tube, the addition amount is 1wt% of the total amount of electrolyte, when the aluminum oxide added to the electrolyte is completely dissolved and the temperature is stable again, add 1wt% to it again alumina, and so on, until the alumina added to the transparent tank no longer dissolves or the life of the quartz crucible expires. Compared with ordinary alumina (single average dissolution time of 10 minutes), the dissolution time of fluorine-loaded alumina (about 4 minutes) is 40% of that of ordinary alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com