Fire coal sulfur fixation, smoke abatement and denitration agent

A technology of denitrification agent and sulfur-fixing agent, which is applied in the fields of coal-burning sulfur-fixing, smoke suppression, and denitrification agent, can solve the problems of ineffective reduction of NO emissions, poor system reliability, and difficulty in popularization and use, and achieves high temperature and prolonged use. Service life, the effect of eliminating coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

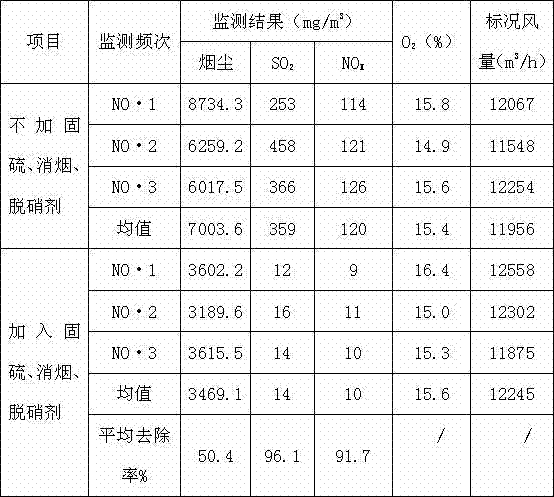

Examples

Embodiment 1

[0019] Embodiment one: Compound carbonate [C a m g (CO 3 ) 2 ]: 40%

[0020] Zeolite: 22%

[0021] Alumina: 18%

[0022] Dicyclopentadienyl iron: 1%

[0023] Urea: 7%

Embodiment 3

[0031] Embodiment three: Duplex carbonate: 46%

[0034] Strontium nitrate: 3%

[0035] Alumina: 2%

[0036] Potassium carbonate: 8%

[0037] Ammonium nitrate: 10%

[0038] Manganese oxide: 6%

[0039] The above-mentioned each component is made into the method of a kind of coal-fired sulfur fixation, smoke elimination, denitrification agent of the present invention is:

[0040] (1) Take each raw material as fine particles with a particle size of 100-200 mesh;

[0041] (2) Take each raw material powder and mix evenly according to the above component ratio to make a loose powder;

[0042] (3) Water can also be added to the powder as needed, and the liquid can be obtained by stirring evenly. According to the moisture content of the coal, the ratio of the powder to water is 1:2-3 (weight ratio);

[0043] (4) When the present invention is in use, it is evenly mixed into the coal in the proportion of 1-5% by weight. If a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com