Electrochromic material, preparation method thereof, glare-proof rearview mirror for automobiles

An electrochromic material and electrochromic layer technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, vehicle parts, etc. Anti-glare effect, avoid image distortion, good mirror effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

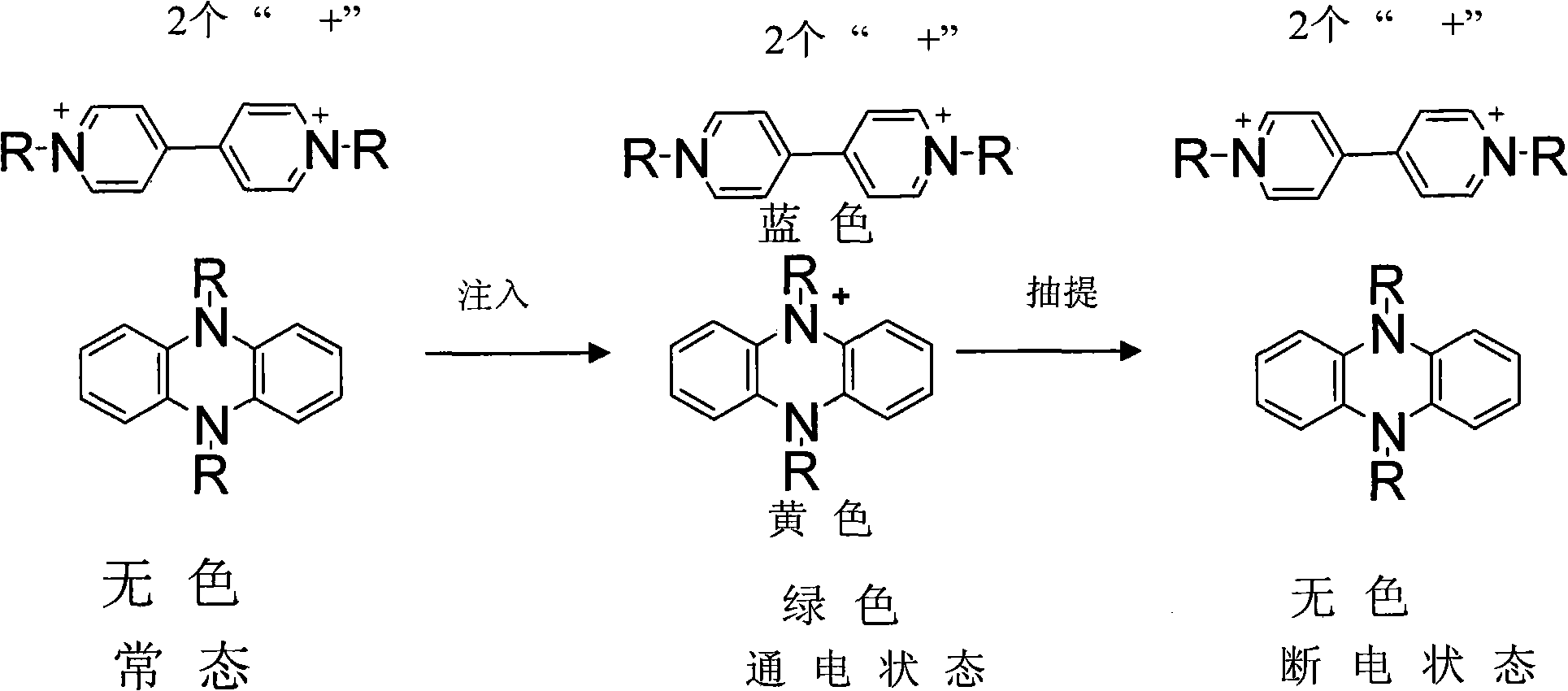

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing the above-mentioned electrochromic material, preferably, the first solvent is one of ethanol, ethylene glycol dimethyl ether, DMF, and acetonitrile, and the second solvent is methanol, ether, or tetrahydrofuran. A kind of, said containing ClO 4 - 、PF 6 - , BF 4 - Compounds containing ClO 4 - 、PF 6 - , BF 4 - salt or acid. The first solvent and the second solvent used in the present invention are preferably the above-mentioned low-toxic or non-toxic solvents, which are non-toxic and environmentally friendly compared with cyanide substances commonly used in the synthesis of electrochromic materials at present.

[0031] The contact mode of the contact reaction between the reaction liquid and the halide of R1 is preferably that the reaction liquid is added dropwise into the halide of R1. The heating method of the heating reaction is preferably microwave, which has high heating efficiency and uniform heating. Therefore, the heating time can...

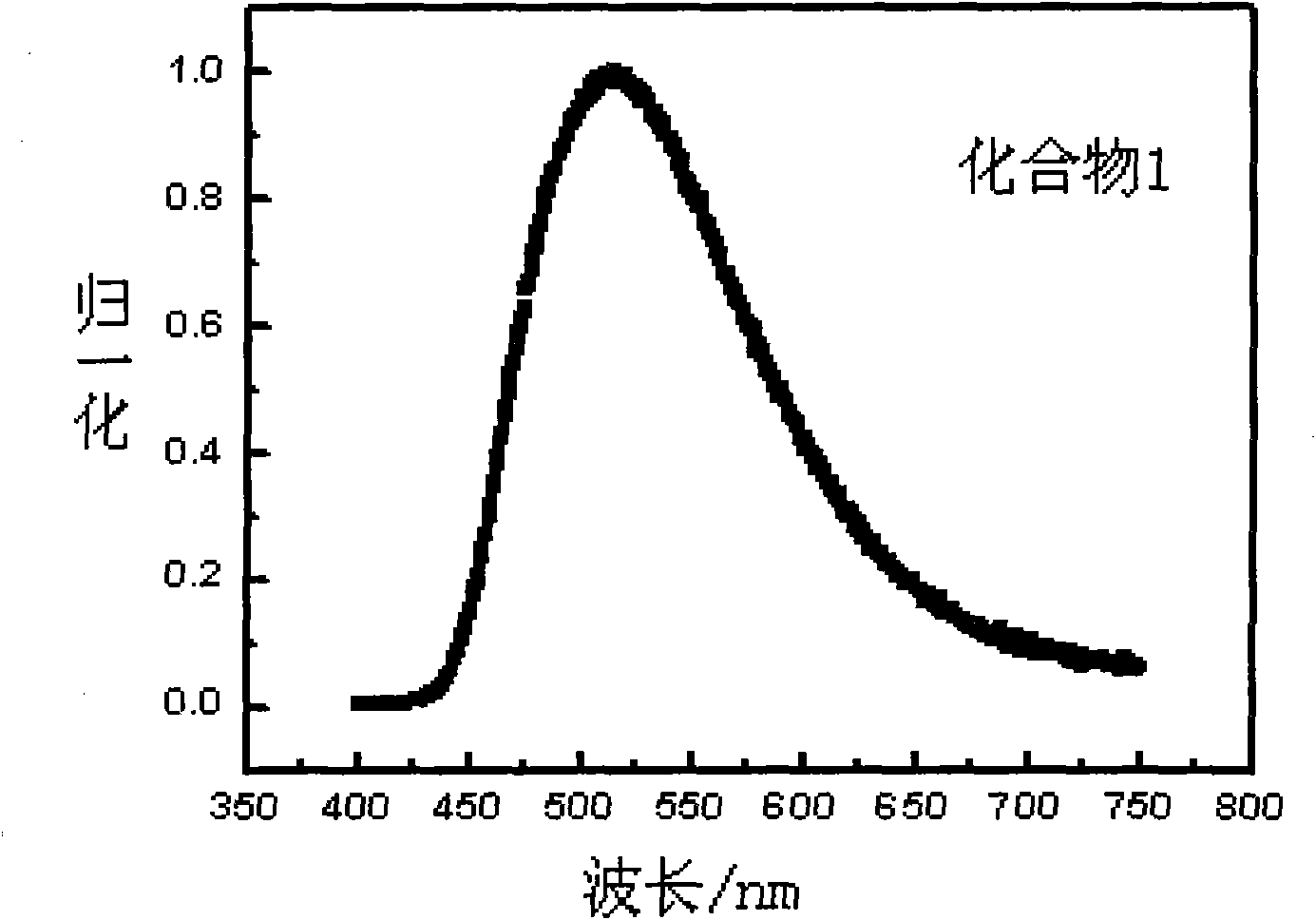

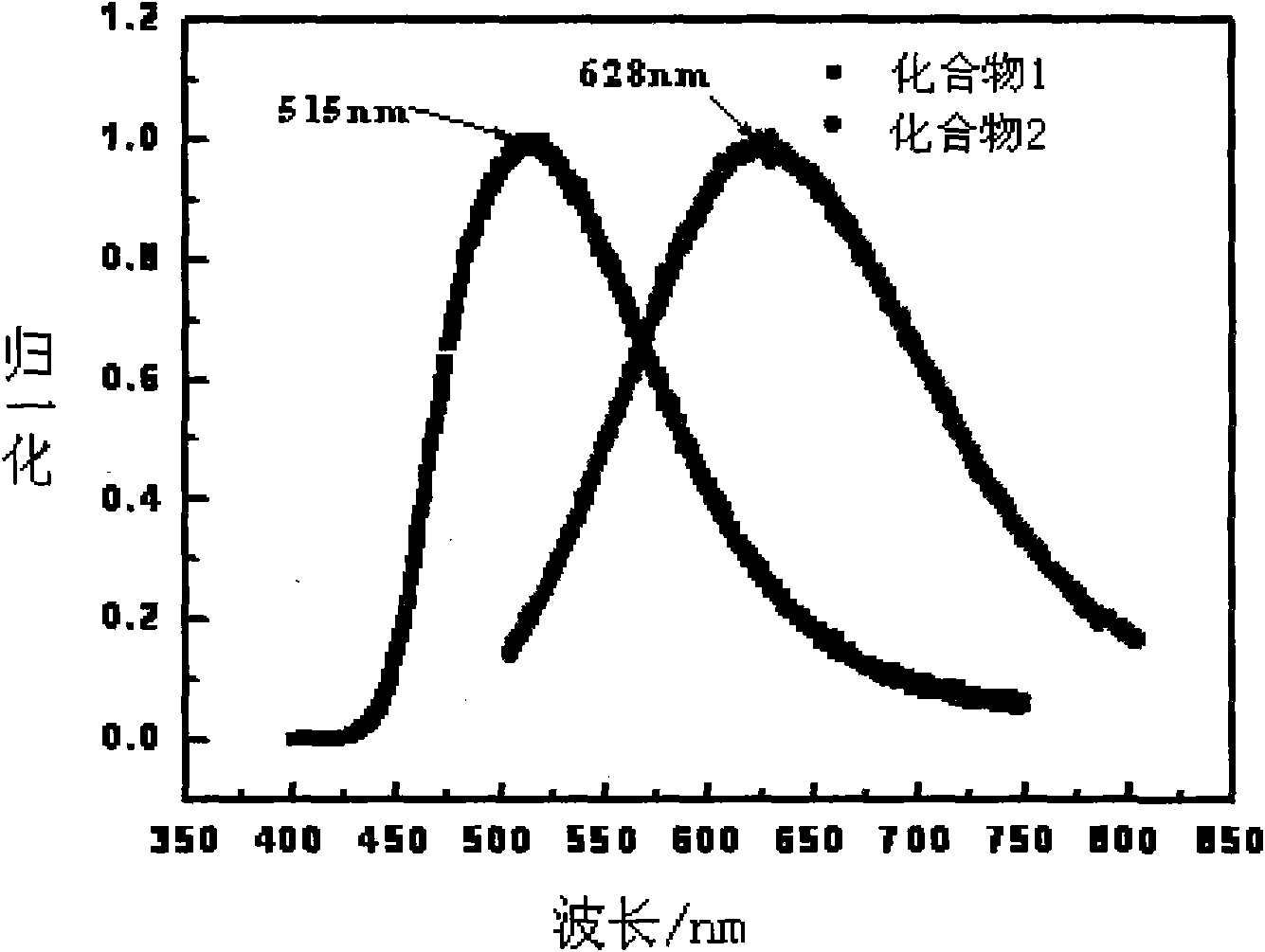

Embodiment 1

[0038] 1) Synthesis of electrochromic materials

[0039] Accurately weigh 1.8g (ie 0.01mol) of phenazine and 0.36g of ethyllithium, add 30mL of ethylene glycol dimethyl ether, reflux for 15min, stir and cool for 0.5h, and drop the reaction solution into 2.36g of 1 , in 4-dibromobenzene, after 30 minutes of dripping, the reaction was continued for 8 hours to obtain 5-(p-bromophenyl)-10-ethyl-5,10-dihydrophenazine solution, which was recrystallized with n-hexane to obtain 2.0 g of yellow needles The powder is 5-(4-bromophenyl)-10-ethyl-5,10-dihydrophenazine.

[0040] Weigh 5-(p-bromophenyl)-10-ethyl-5,10-dihydrophenazine and 4,4-bipyridine in a three-necked flask according to a molar ratio of 2:1, add 25 mL of methanol, and place in a microwave The reaction was carried out by rotation for 15 minutes, and the black solid obtained by rotary evaporation was recrystallized with deionized water to obtain 1.6 g of the electrochromic material A1 of the present invention, with a yield ...

Embodiment 2

[0044] 1) Synthesis of electrochromic materials

[0045] Accurately weigh 1.8g (that is, 0.01mol) of phenazine and 0.22g of methyl lithium, add 30mL of ethylene glycol dimethyl ether, reflux for 15min, stir and cool for 0.5h, and drop the reaction solution into 2.36g of 1 , in 2-diiodoethylene, after 30 minutes, the reaction was continued for 8 hours to obtain 5-(2'-iodovinyl)-10-methyl-5,10-dihydrophenazine solution, which was recrystallized with n-hexane to obtain 2.0g The yellow needle powder is 5-(2'-iodovinyl)-10-methyl-5,10-dihydrophenazine.

[0046] Weigh 5-(2'-iodovinyl)-10-methyl-5,10-dihydrophenazine and 4,4-bipyridine in a three-necked flask according to a molar ratio of 2:1, add 25 mL of ethanol, and Rotate and react in a microwave oven for 13 minutes, filter the reaction product and react with potassium fluoroborate solution with stirring, and recrystallize the solid substance with deionized water to obtain the electrochromic material A2 of the present invention....

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com