Anti-dazzle Thin Film And Liquid Crystal Display Device

A liquid crystal display device and film technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as glare and insufficient precision of concave and convex shapes, achieve good contrast and wide viewing angle characteristics, and prevent visual recognition Reduced, excellent anti-glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

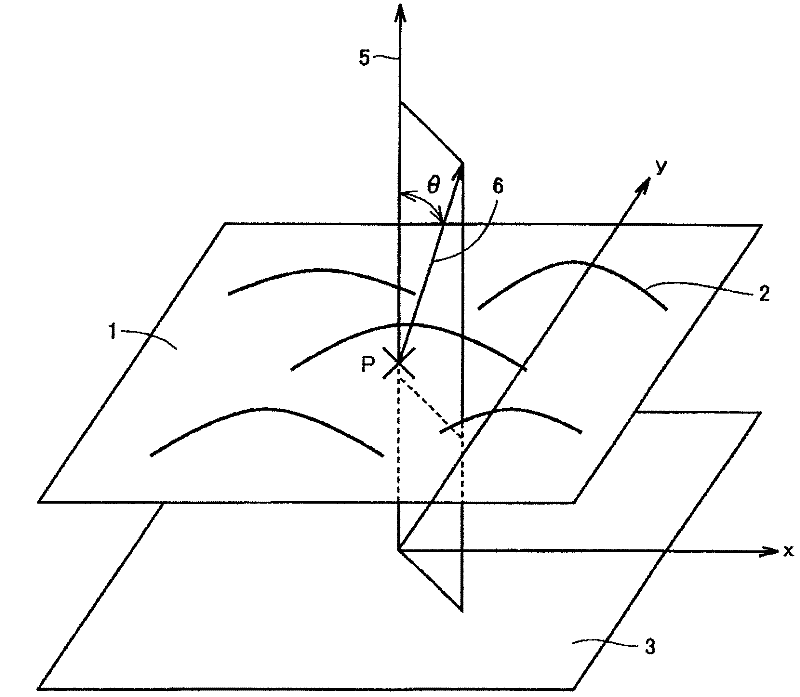

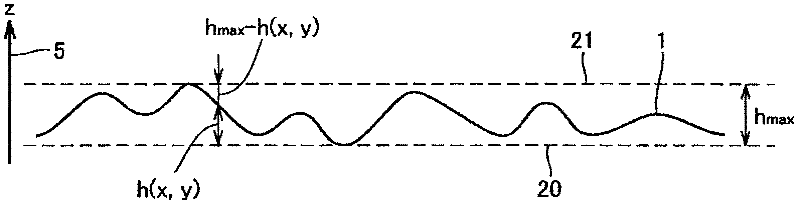

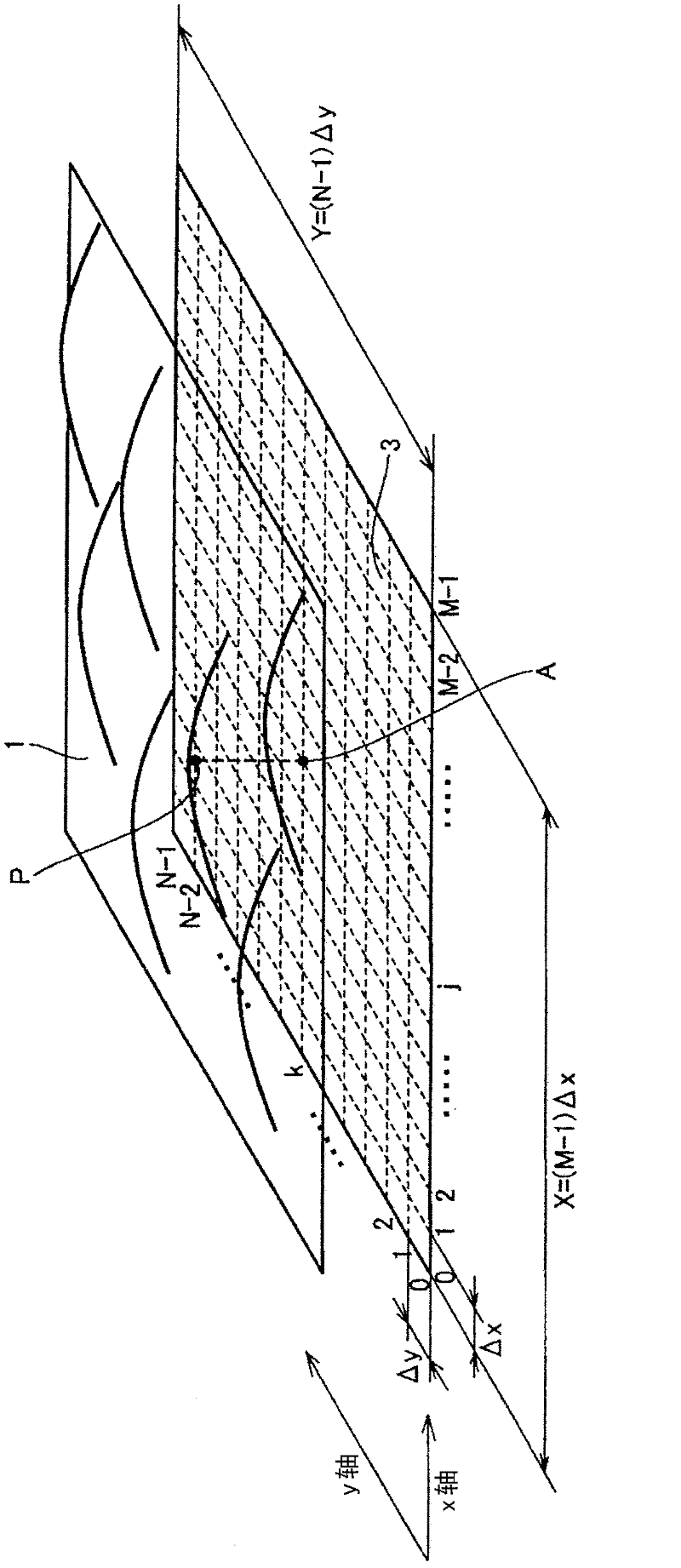

[0255] (Preparation of molds for anti-glare film production)

[0256] The roll which gave the ballard copper plating to the surface of the aluminum roll (A5056 of JIS) of diameter 200mm was prepared. Ballard copper plating consists of copper plating layer / thin silver plating layer / surface copper plating layer, and the overall thickness of the plating layer is set to 200 μm. The copper-plated surface is mirror-polished, a photosensitive resin is coated on the polished copper-plated surface, and dried to form a photosensitive resin film. Next, the following pattern is exposed and developed on the photosensitive resin film by laser light, and the pattern is Figure 16 The pattern shown (by removing 0.035 μm from the pattern with random brightness distribution -1 Below the low spatial frequency components and 0.15μm -1 The band-pass filter of the above high spatial frequency components) is repeated and juxtaposed. Laser exposure and development were performed with Laser Stream...

Embodiment 2

[0265] A mold B was produced in the same manner as in Example 1 except that the etching amount of the second etching process was set to 8 μm, and an antiglare film B was produced in the same manner as in Example 1 except that the mold B was used.

Embodiment 3

[0267] A mold C was produced in the same manner as in Example 1 except that the etching amount of the second etching process was set to 10 μm, and an antiglare film C was produced in the same manner as in Example 1 except that the mold C was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com