Method for producing 1,6-dimethyl adipate

A technology of dimethyl adipate and a production method, which is applied in the field of dimethyl adipate production using solid acid as a catalyst, can solve the problems of large catalyst consumption, equipment corrosion, complicated process and the like, so as to eliminate the need for filtering Steps, save operating costs, improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

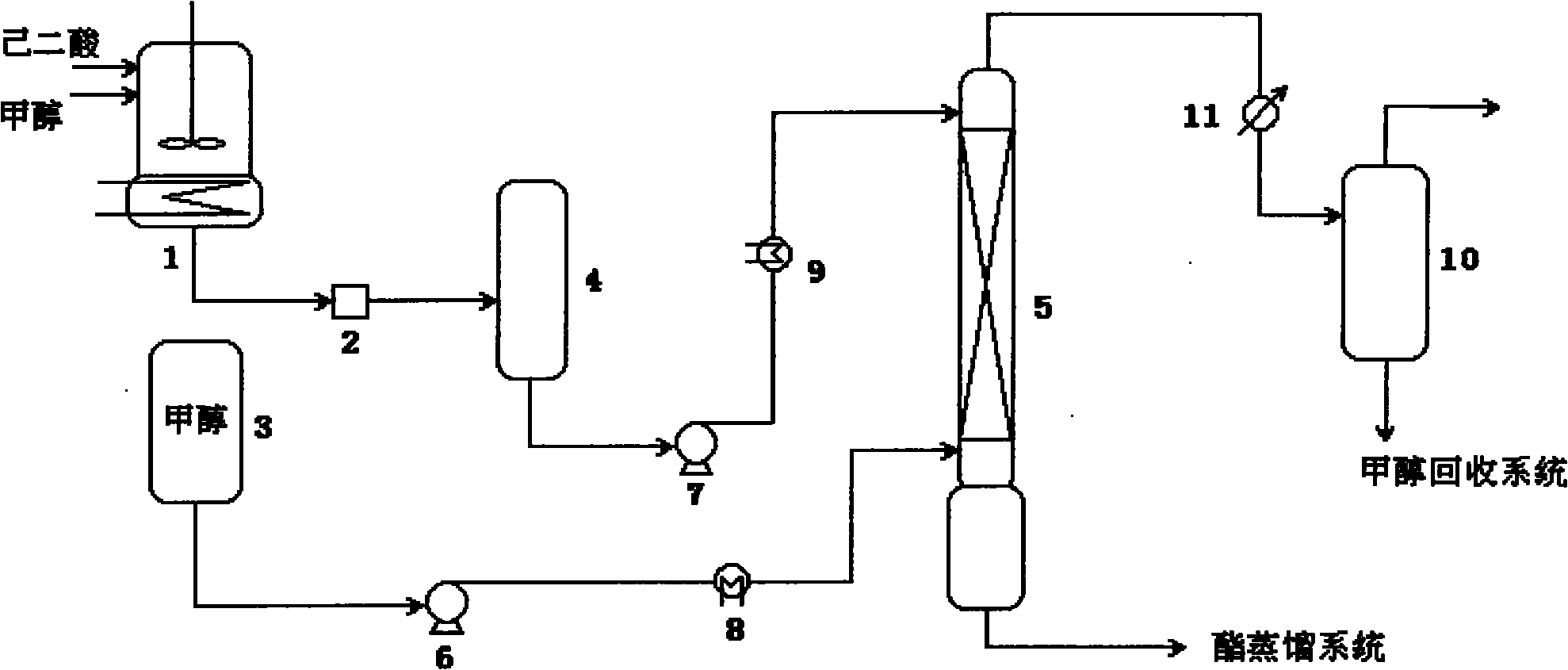

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 pre-esterification experiment

[0024] Mix methanol and adipic acid at an alcohol / acid molar ratio of 3 to 5, heat to an appropriate reaction temperature and reaction pressure (reaction pressure is measured by gauge pressure, and gauge pressure refers to a pressure value higher than atmospheric pressure), under the condition of no catalyst, adipic acid The pre-esterification reaction between the acid and methanol occurred, and the experimental results are shown in Table 1 (the conversion rate of adipic acid is calculated according to the analysis result of the acid value of the product).

[0025] Table 1 Pre-esterification reaction conditions and results

[0026]

Embodiment 2

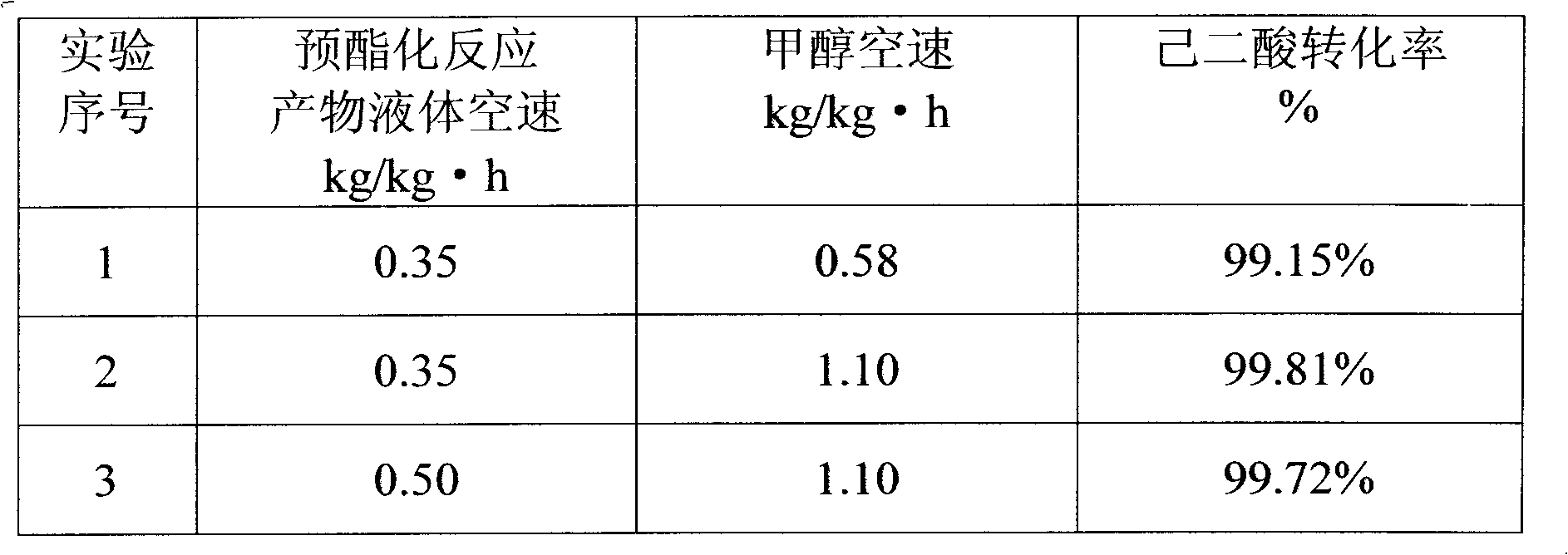

[0029] Esterification experimental results under different space velocities of embodiment 2

[0030] Utilize the mixed material after the pre-esterification reaction of Example 1 to carry out the continuous esterification experiment, use the DNW-II type resin produced by Dandong Mingzhu Special Resin Co., Ltd. as the catalyst, adopt catalytic rectification reaction, and set 10 blocks in the catalytic rectification tower Trays, the resin catalyst is evenly distributed on each tray. The operating pressure is normal pressure, the temperature at the bottom of the tower is 120°C, and the temperature at the top of the tower is 95°C. The reaction results under different conditions are shown in Table 2.

[0031] Table 2 Catalytic distillation esterification reaction conditions and results

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com